Overview

In 2017 I published the first iteration of this project. And since then, the cat feeder had been daily working. The mechanics is still the same and has proven its reliability over years.

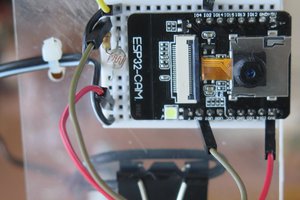

Software has changed, starting using AI (a failure at that time), then using an old smartphone as a webcam. And now using a much more compact and cheap solution !

Here is what it looked like in 2017:

Sadly, Chicha (my cat in the video) died last year and won't be there for another video today...

Lessons learnt

Here are the lessons learnt during 8 years of daily operations:

- Ants love cat kiddles... When dish is on the floor, the day after it will be full of ants. So the dish must "float" in the air

- Cat is a hunter, he always prefer squirrels or birds or mouses to kiddles. If you feed it with the same amount of food, the day after the dish will overflow (and feed the ants !)

- kibbles are like a "3d tetris game" they tend to fall and intricate and block the feeder. A reliable anti jam feature is mandatory

- high capacity feeders are a must to take one month vacation for instance... But detecting that the feeder is empty is also needed

- notification that your cat is eating is fun but should occur only when your cat is eating and not when somebody is in front of the dish !

- Seeing your cat eating is a smart feature, not really mandatory but so fun !

We will see how these concerns have been addressed.

Mechanical design

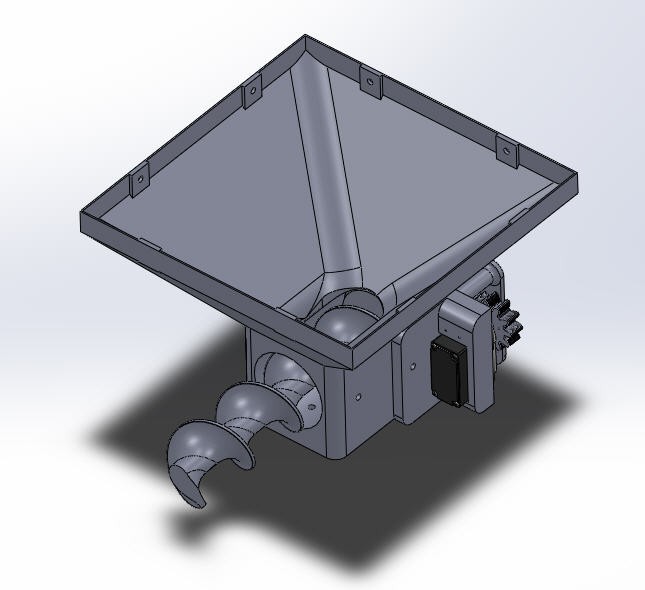

Mechanical design is based on a pyramidal hopper which is dropping the kibbles on a big worm screw auger.

The worm screw is driven by a 360° RC servo and two gears.

A 360° servo allows a continuous rotation in both direction CW or CCW.

A 360° servo allows a continuous rotation in both direction CW or CCW.

Anti jamming :

to prevent blocking the worm gear, motion is controlled in both directions by software. This will "shake" the kibbles and help them drop from the hopper into the worm gear.

To avoid blocking the worm gear in "forward motion" a rubber lip is glued into the hopper on its front side. This soft lip will absorb all the constraints and, together with the back and forth motion, prevent any jamming. Trust me it works !

As you can see on this picture a PVC pipe is inserted around the worm gear and a slot is cut on top of it to allow kibbles to drop into the worm gear.

PVC is perfect to allow a friction less motion into the pipe. It is strong, very soft and naturally shiny (almost "oiled").

Weighing the dish

Weighing the dish is an idea which fixes a lot of concerns explained above!

- the dish will "float" above the ground preventing ants to eat the kibbles

- when the cat is eating, weight of the dish dicreases. It's an elegant way to detect "cat eating" event

- when the kibbles are dropping we can measure the exact ration we want to deliver to the cat and stop worm screw motion

- if the dish is not empty, we only fill it to the exact ration, preventing "overflow"

- if the kibbles do not fall it is either a jam situation or an empty hopper one. A notification can be sent to your smartphone

- finally, the green dish of the video sits above the 3d printed one. You can easily remove it for washing and to keep it clean.

So a load cell is added under the hopper it acts as a kitchen scale !

![]() Outer walls assembly

Outer walls assembly

Finally, as shown on the picture, wooden walls are added around the hopper. They are fixed together using 3d printed feets and 5mm wood screws. Dimensions to cut the 18mm plywood are given into the 3d printed parts package (.dxf files).

Here is an exploded view: Assembly of all these parts is fairly easy and straightforward

As you can see holes are drilled into the front wall to accommodate the camera and the motion detector (IR sensor).

As you can see holes are drilled into the front wall to accommodate the camera and the motion detector (IR sensor).

Printing the catfeeder

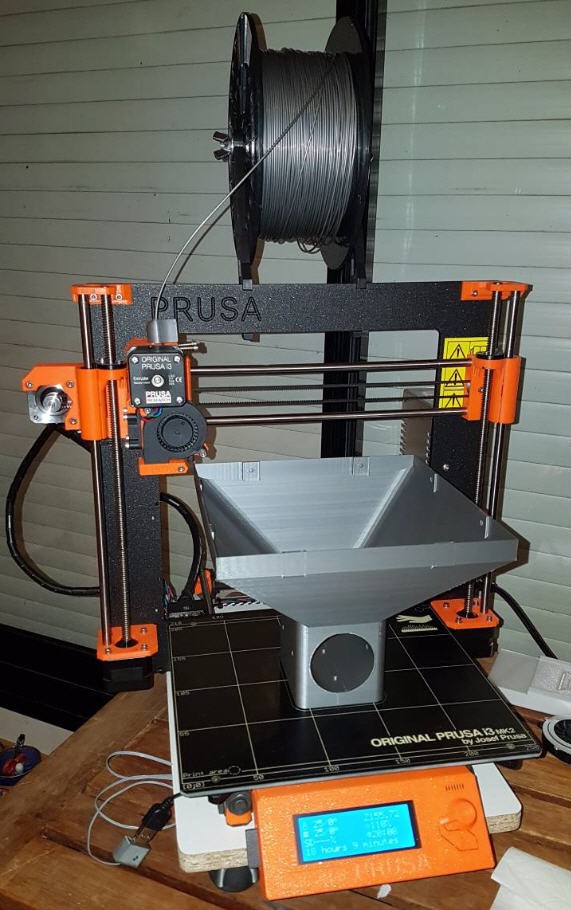

Most of the parts are printed with PLA filament.

The biggest one is the hopper ! It can however be printed directly on my Prusa i3 Mk2.s printer without any support.

The auger must be as strong as possible and as smooth as possible. For these...

Read more » JP Gleyzes

JP Gleyzes Outer walls assembly

Outer walls assembly

Marc-Antoine Lalonde

Marc-Antoine Lalonde