PCB DESIGN PROCESS

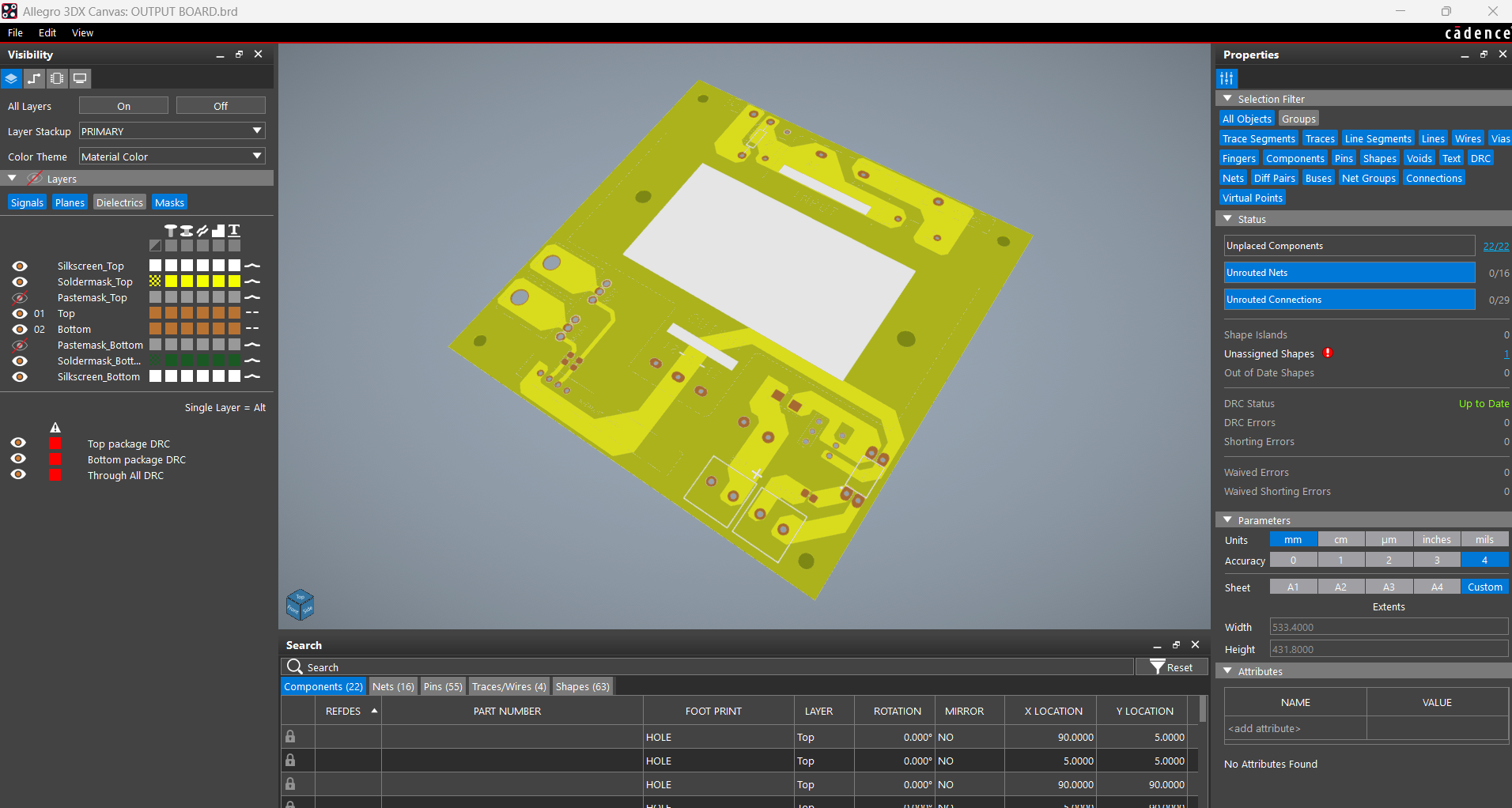

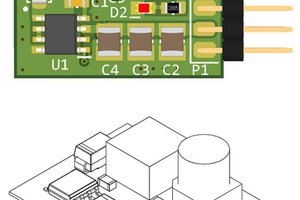

We begin this project by designing the PCB, which consists of two primary sections for modularity.

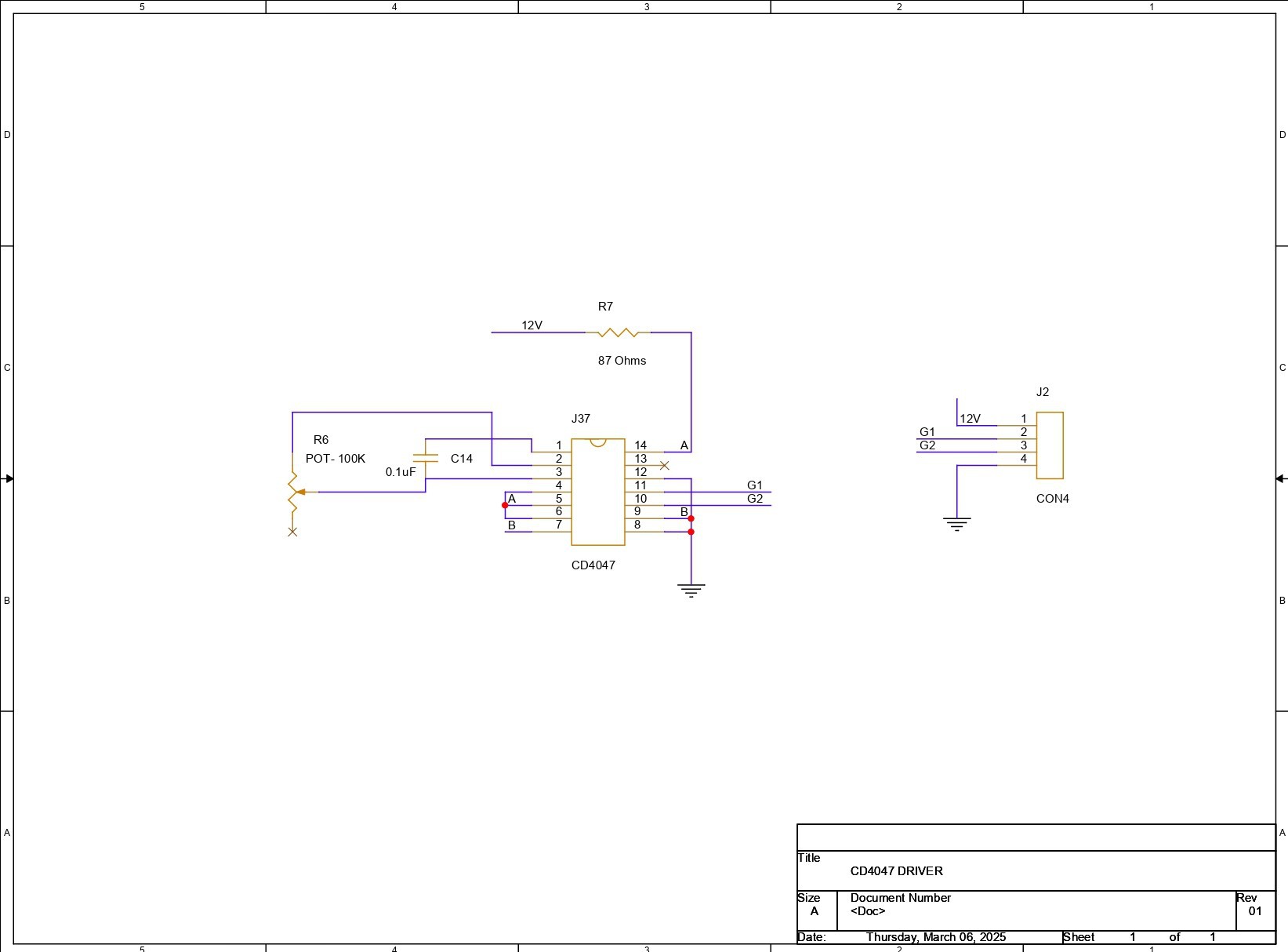

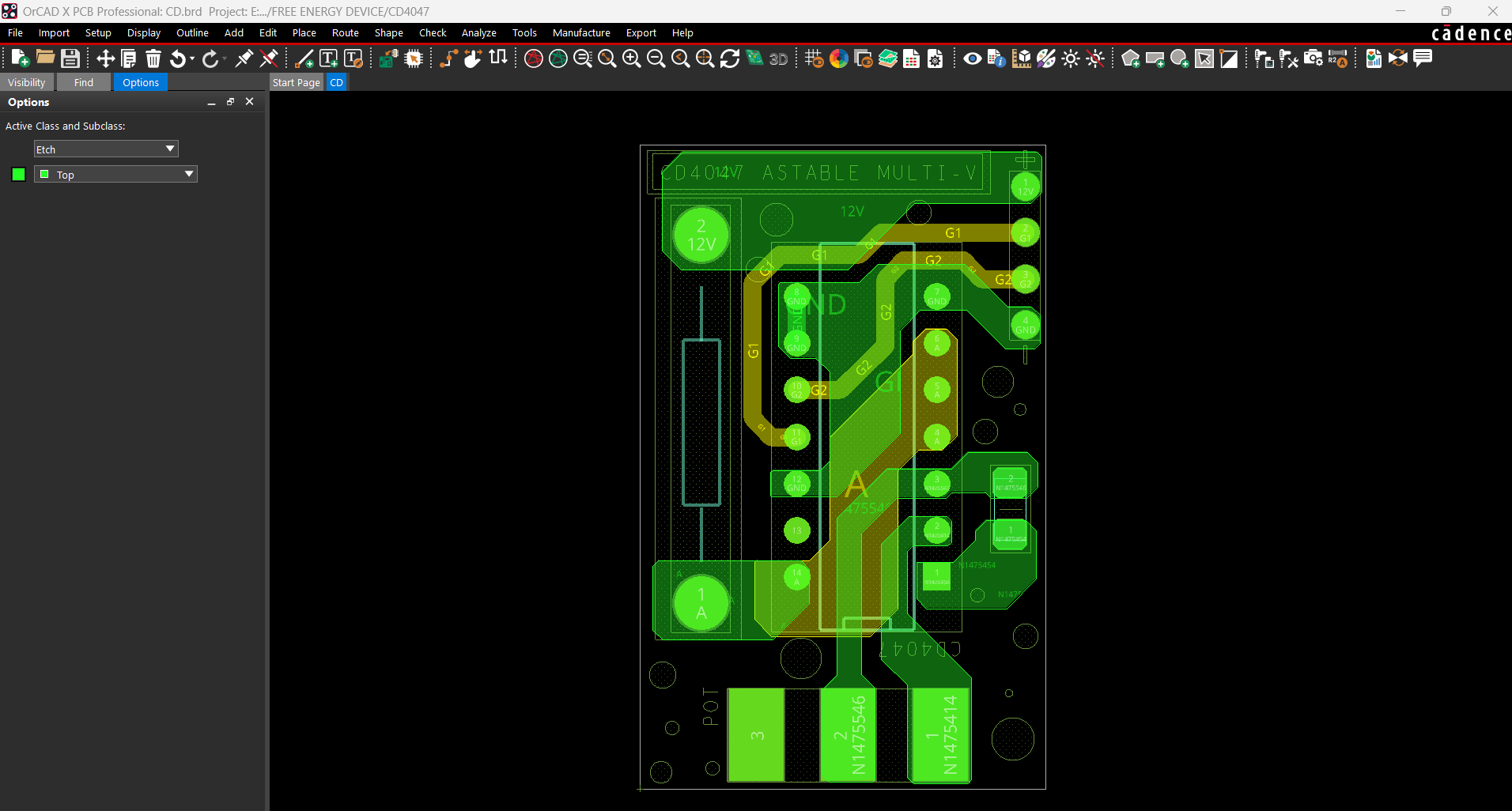

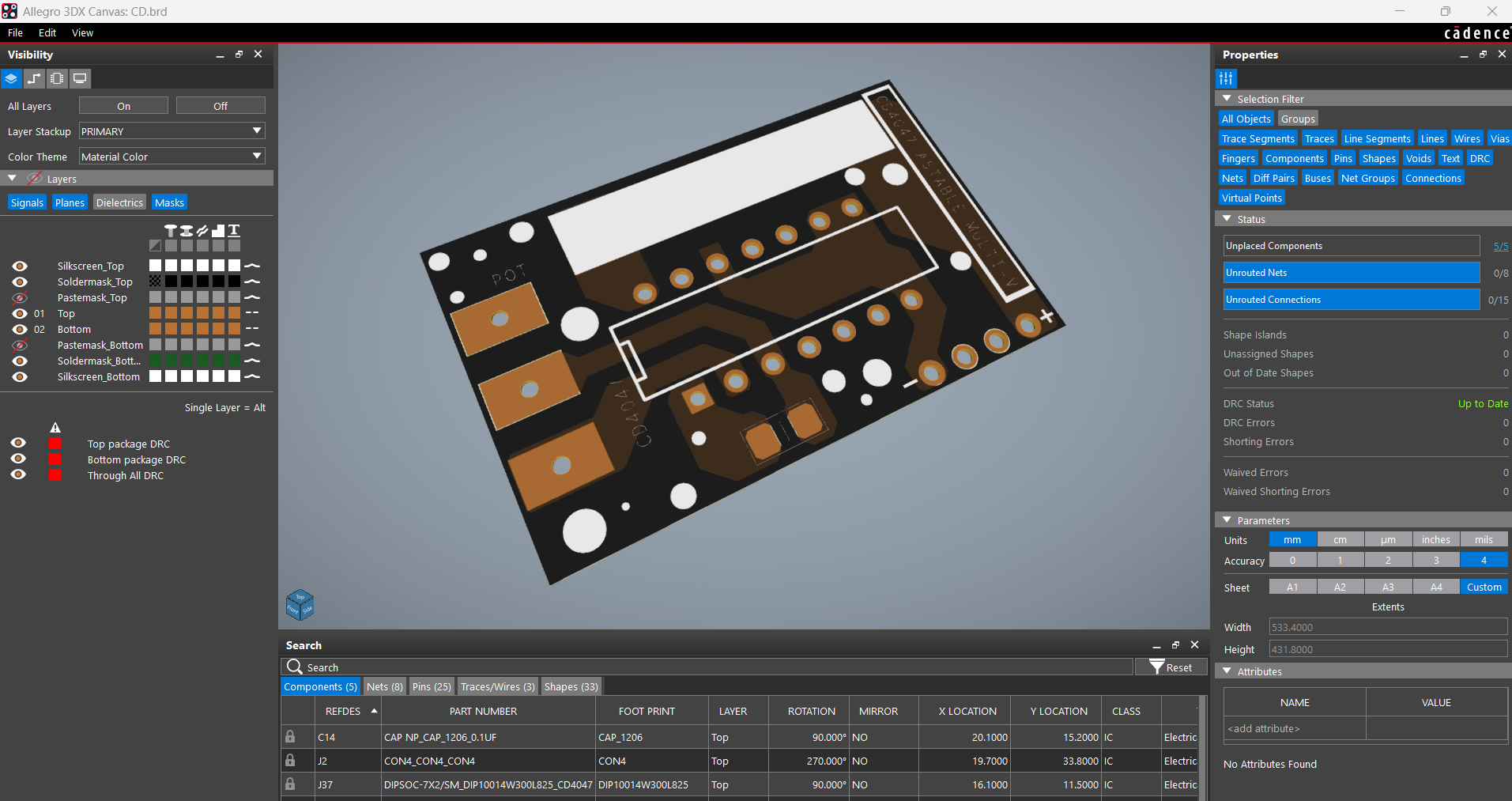

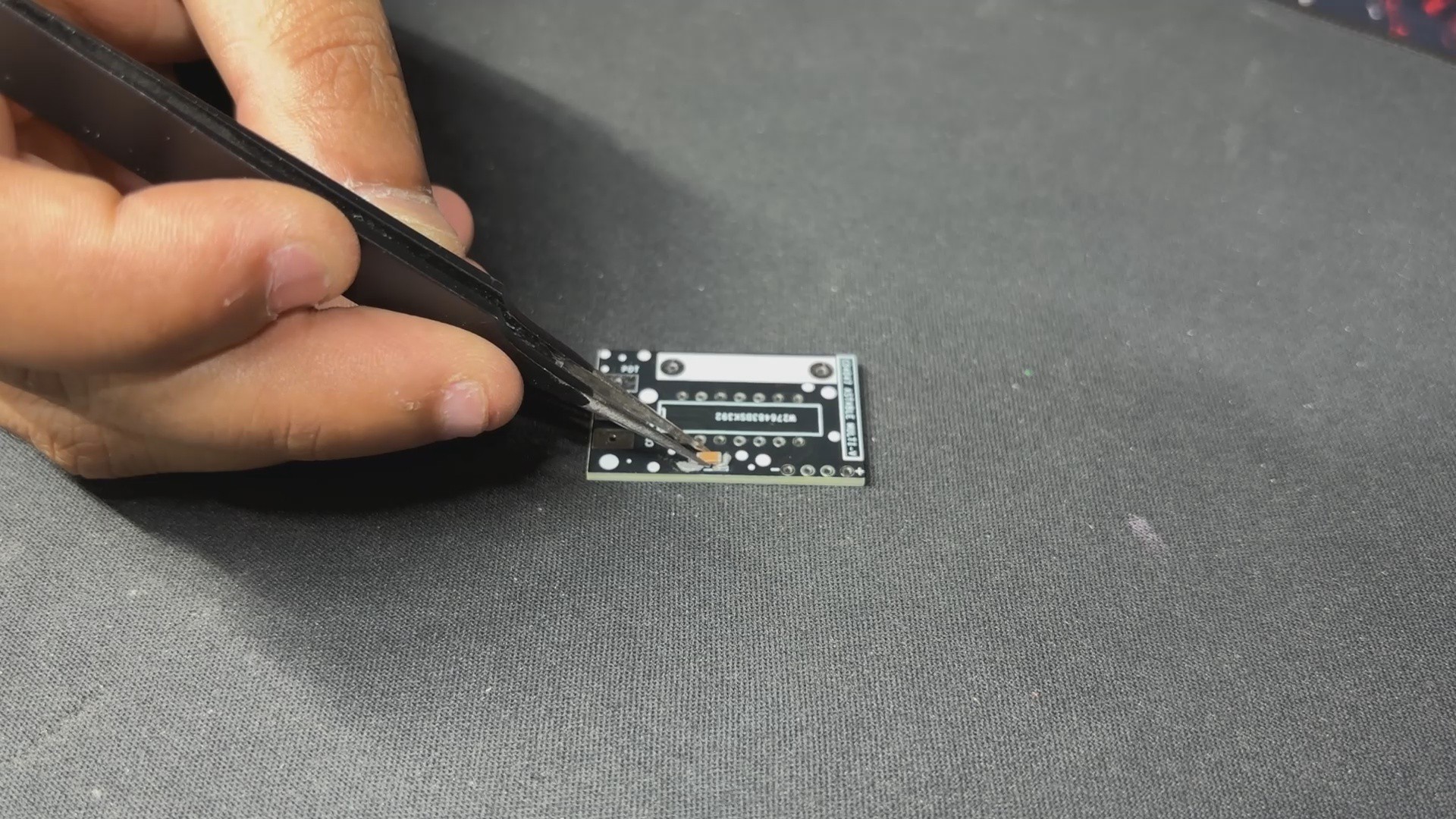

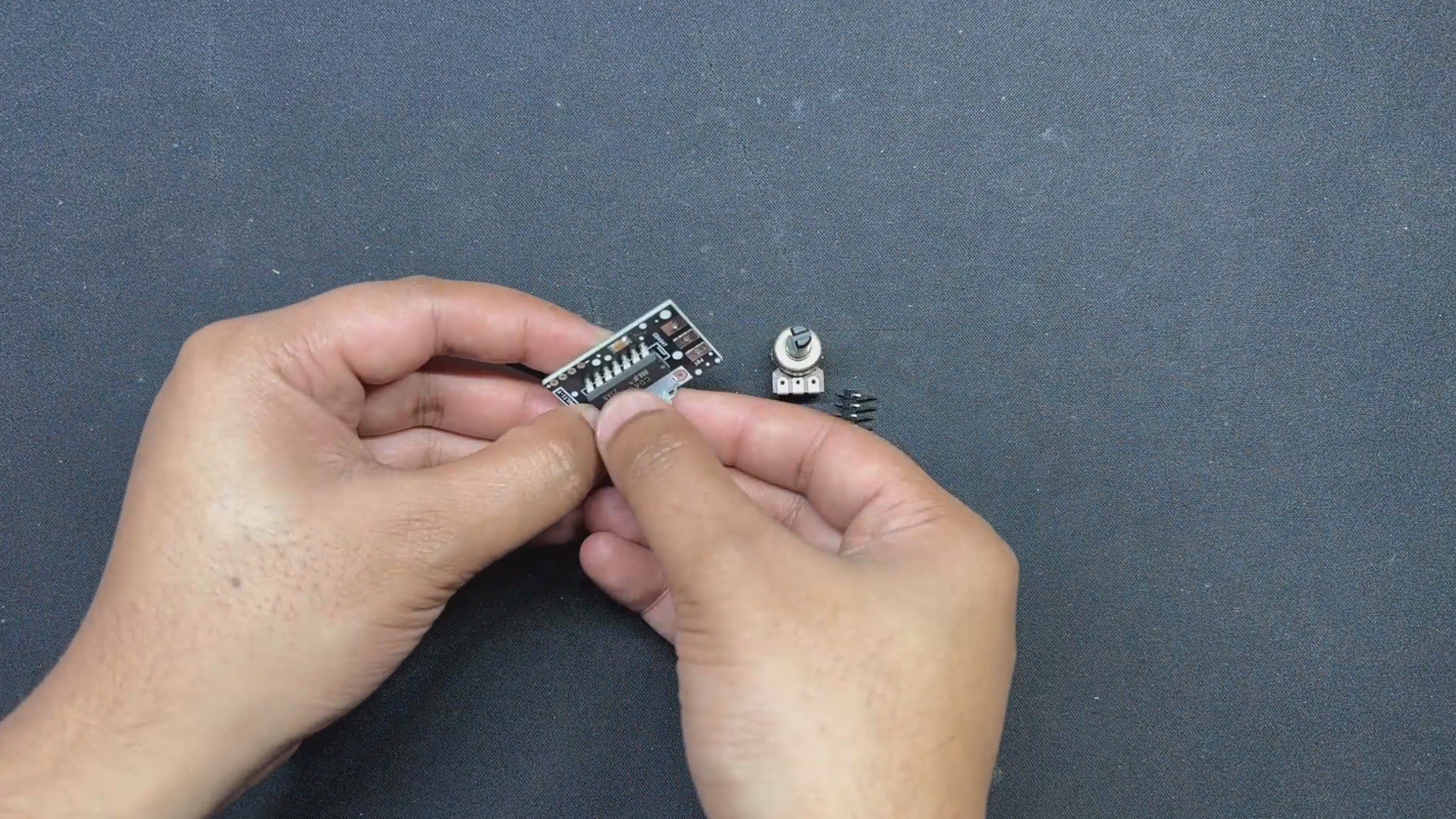

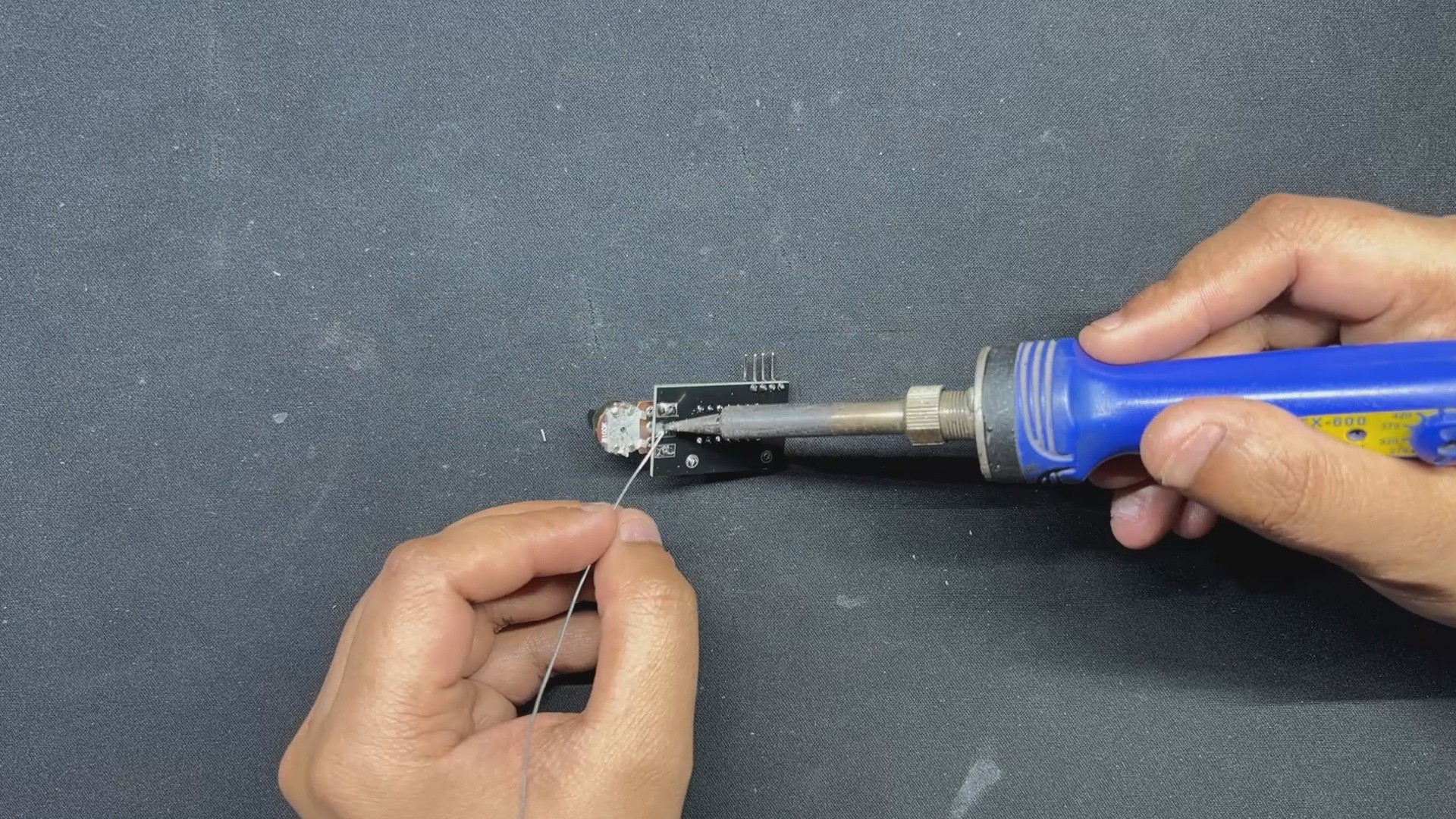

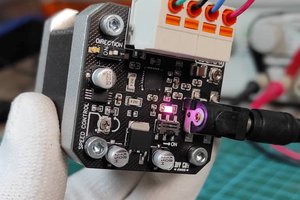

The CD4047 Driver is the initial section, which consists of the CD4047 IC, a potentiometer, and a load resistor. The CD4047 IC generates square wave pulses, and the frequency can be adjusted using the potentiometer. This provides fine control over the output frequency, which is generally set to 50 Hz or 60 Hz for normal AC applications. The load resistor ensures that the CD4047 IC's output pulses remain stable.

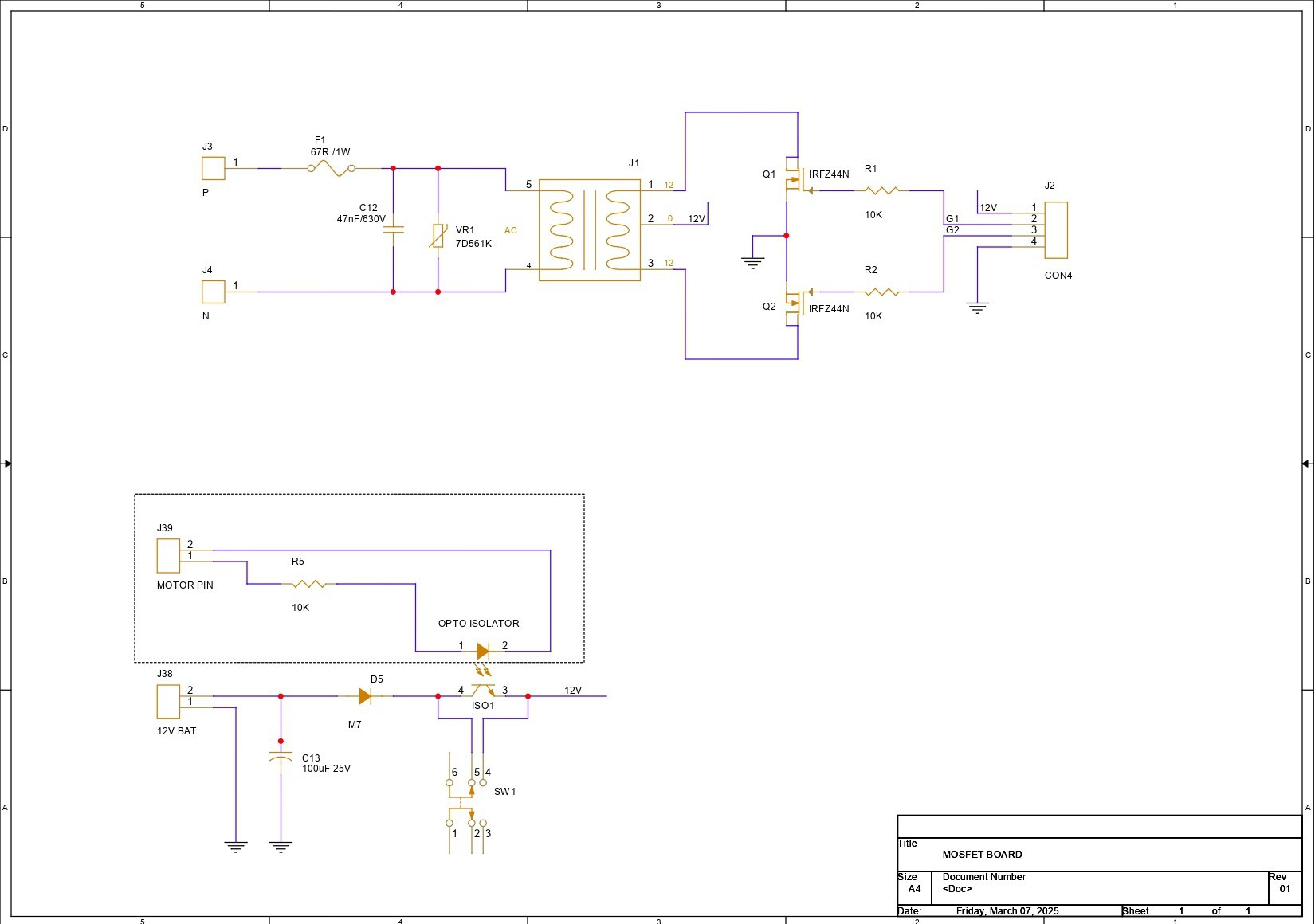

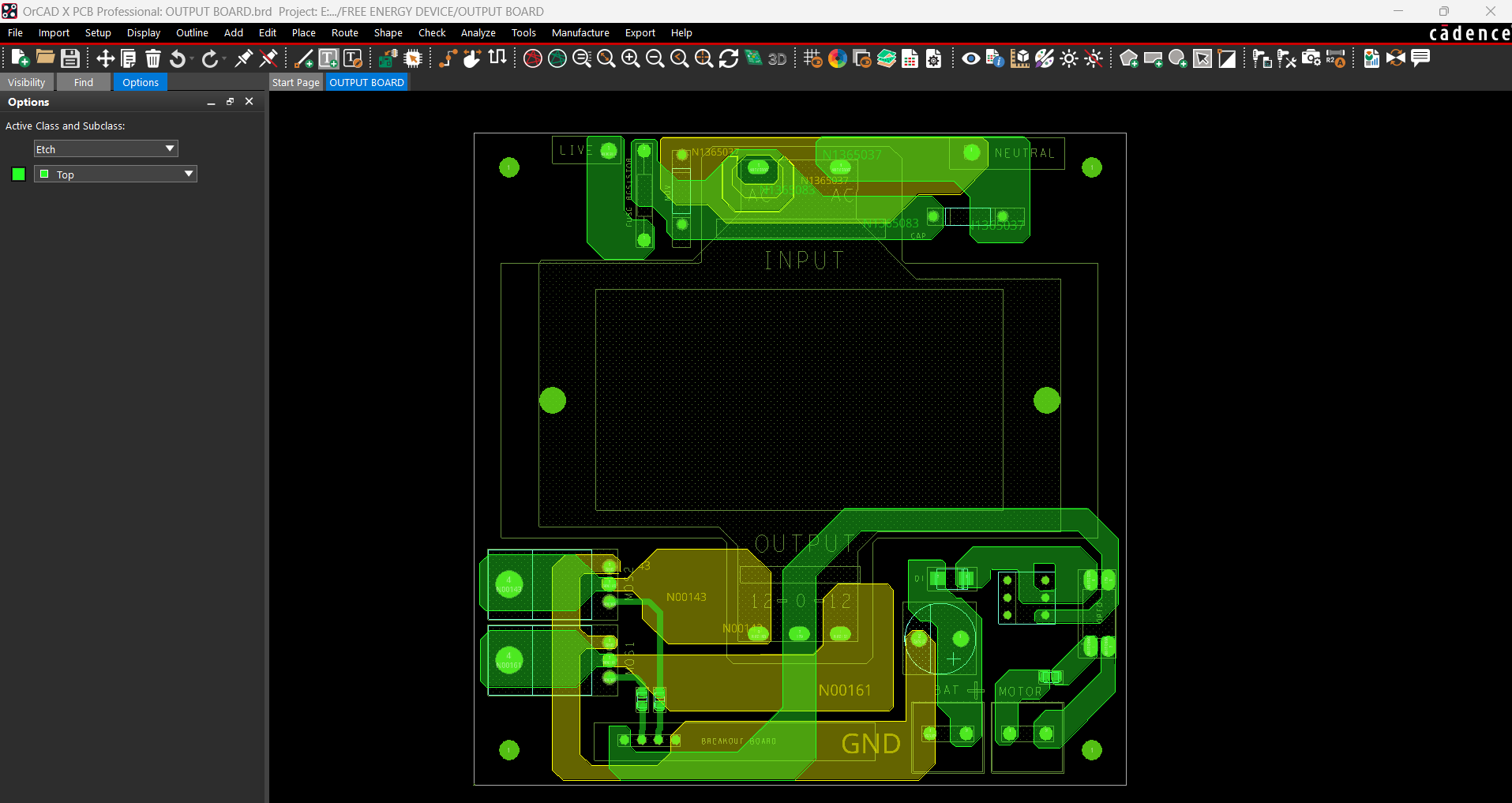

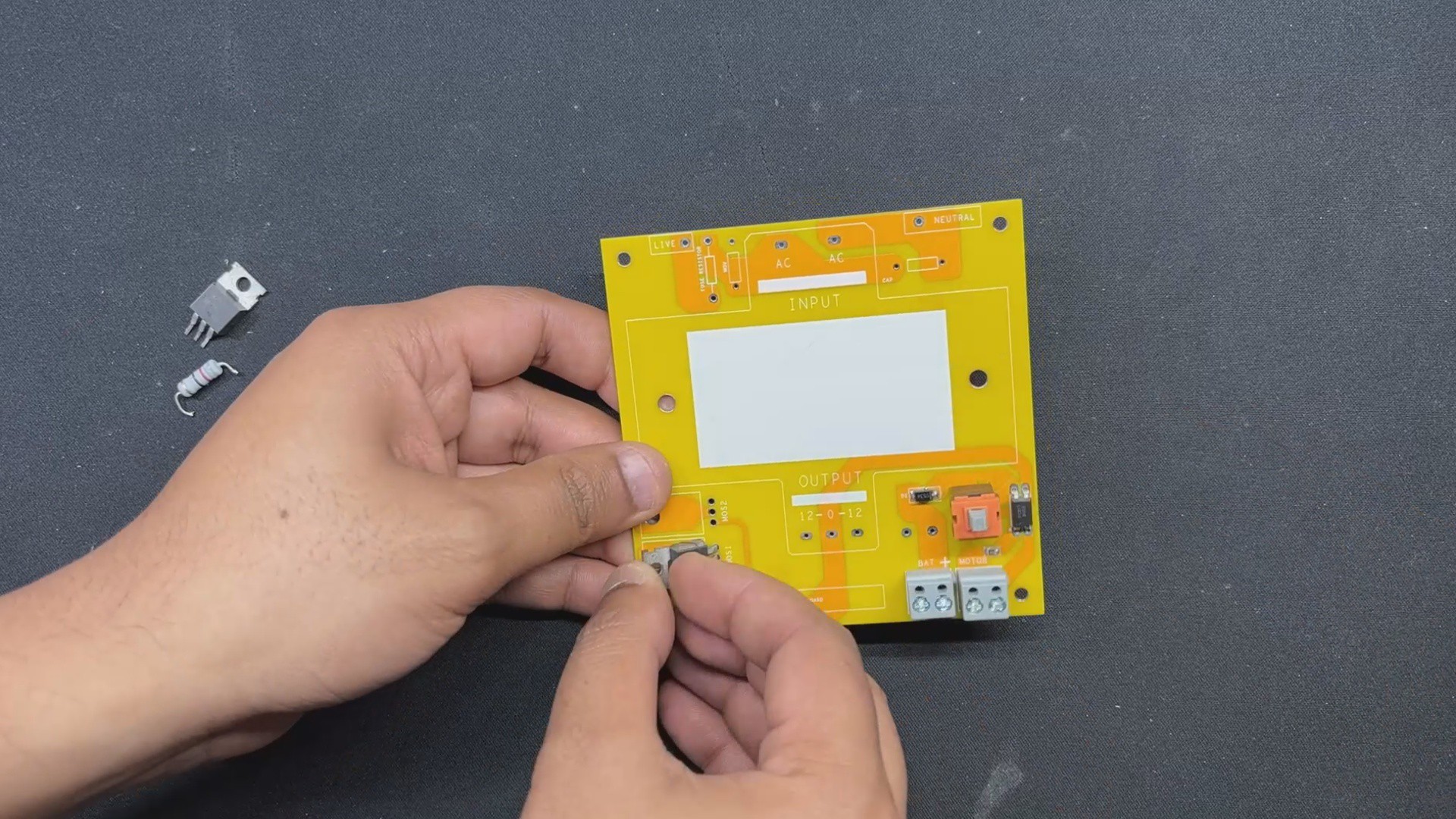

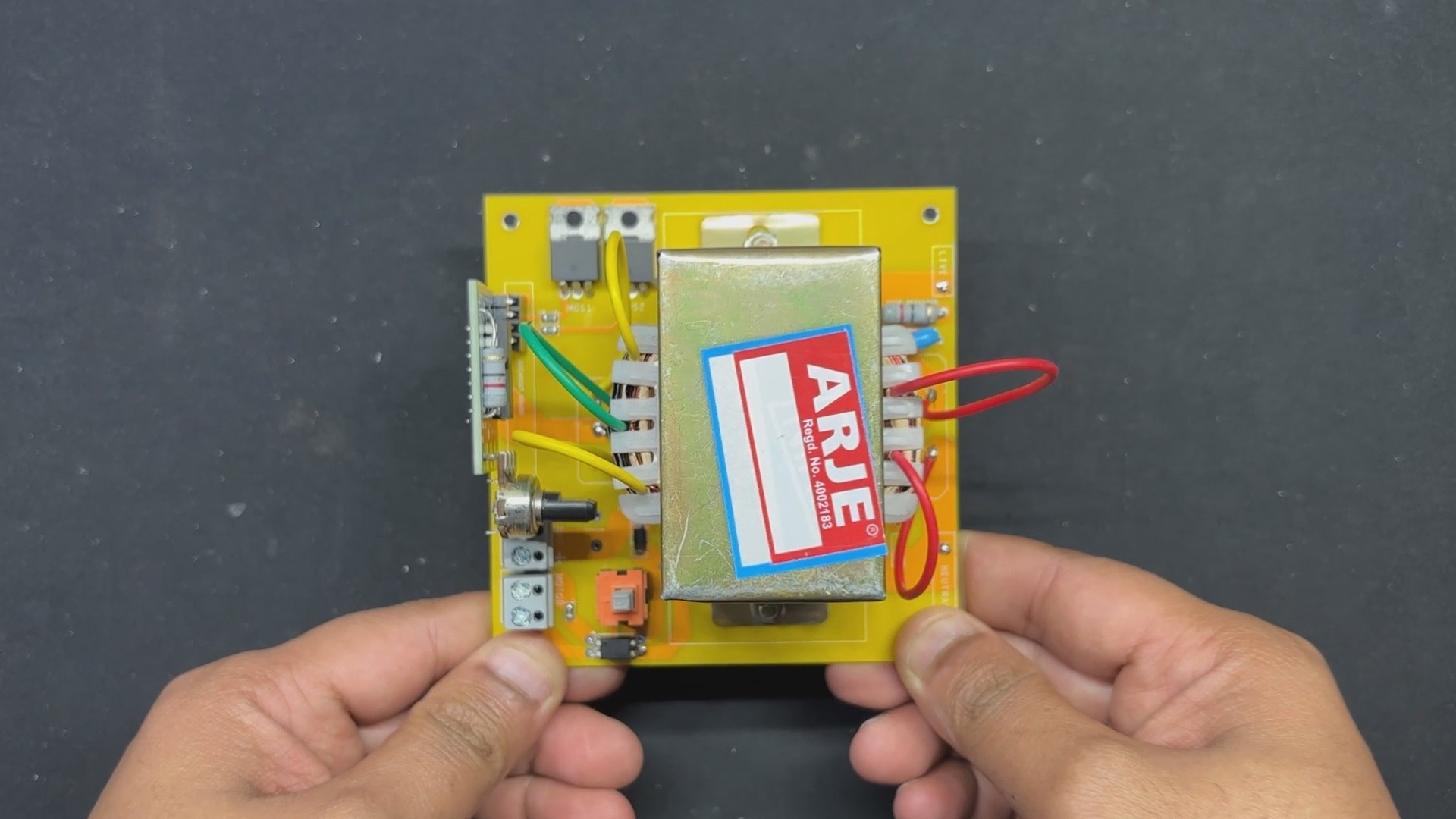

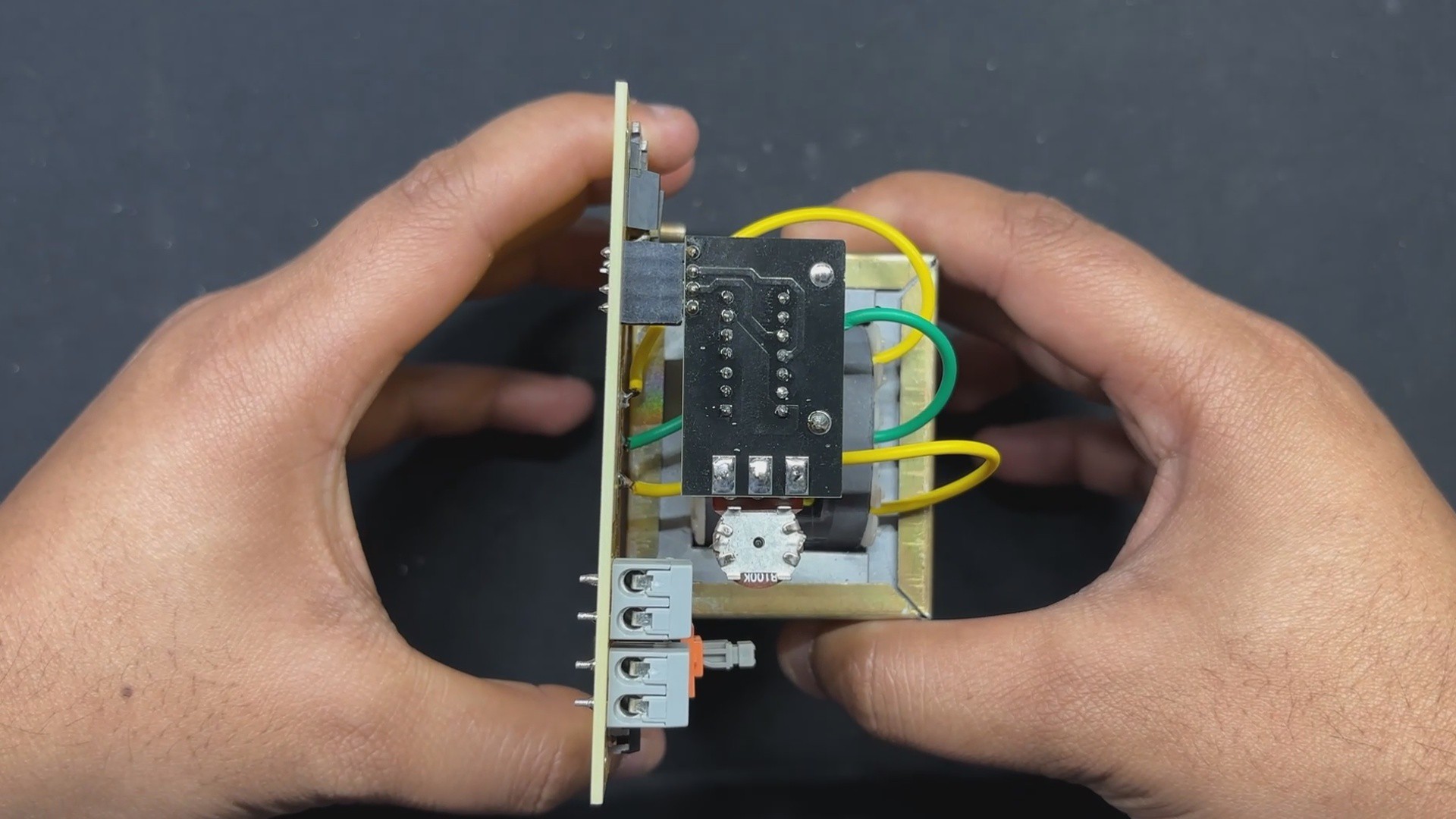

These pulses are then sent into the circuit's second section, the MOSFET BOARD, which includes MOSFETs, a transformer, capacitors, and other essential components.

The MOSFETs amplify the square wave pulses received from the CD driver by turning on and off, enhancing the signal. The amplified signal is then fed into the transformer's primary winding, which increases the voltage to the necessary AC level.

The transformer turns the amplified square wave signal into a higher-voltage AC output. Capacitors are employed to filter the output, resulting in a smooth AC waveform with little noise and ripples. This arrangement simplifies troubleshooting and upgrading while also improving heat management by dispersing components across multiple boards. As a result, the inverter efficiently transforms 12V DC power into a uniform AC voltage, making it suited for a variety of applications that require AC power from a DC source.

This board also has two mounting holes, so the transformer can be securely attached with nuts and bolts to the circuit.

We've also added CON 2 screw terminals, via which we'll connect a 12V lithium battery pack to the circuit.

PCBWAY Service

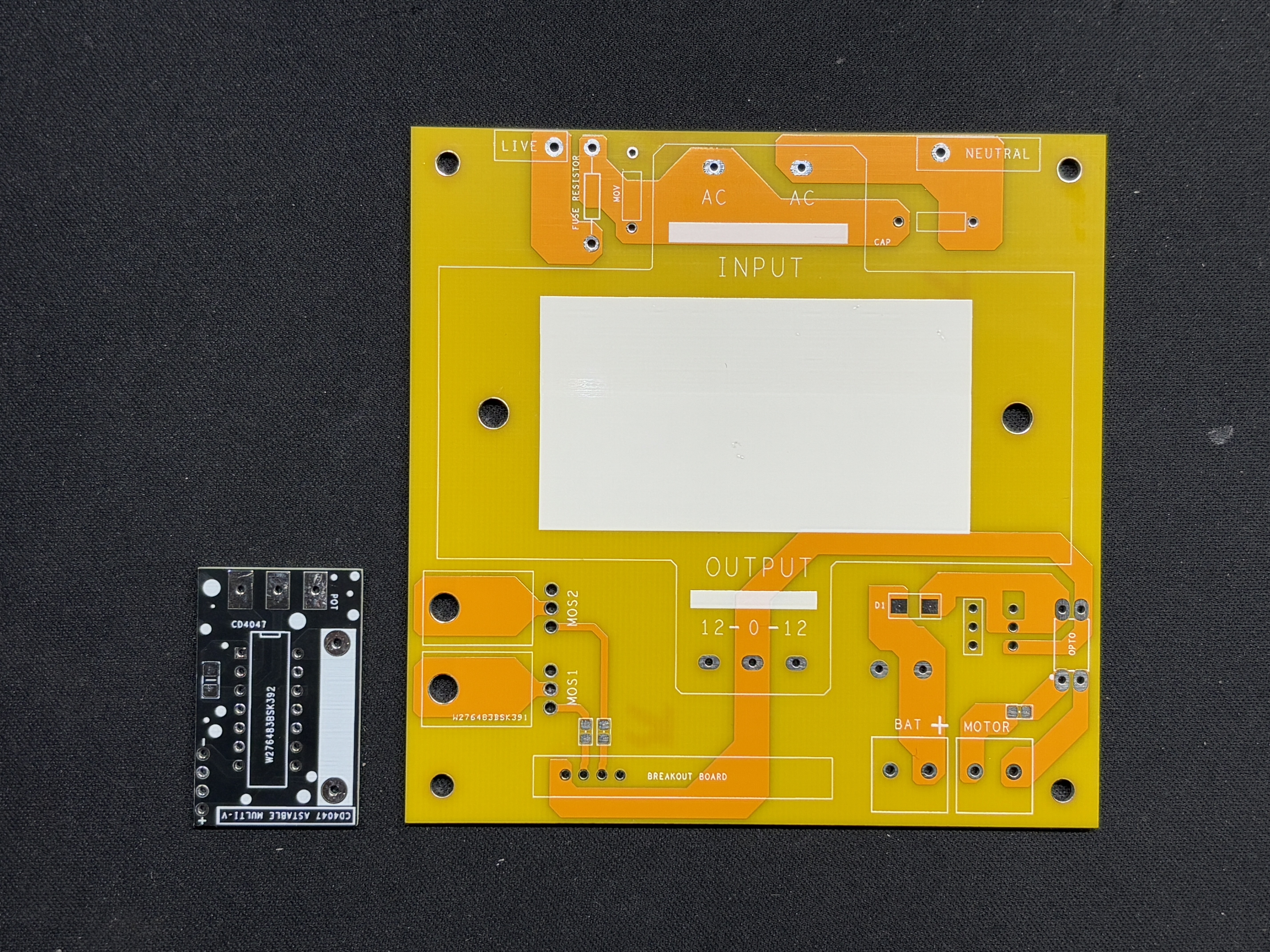

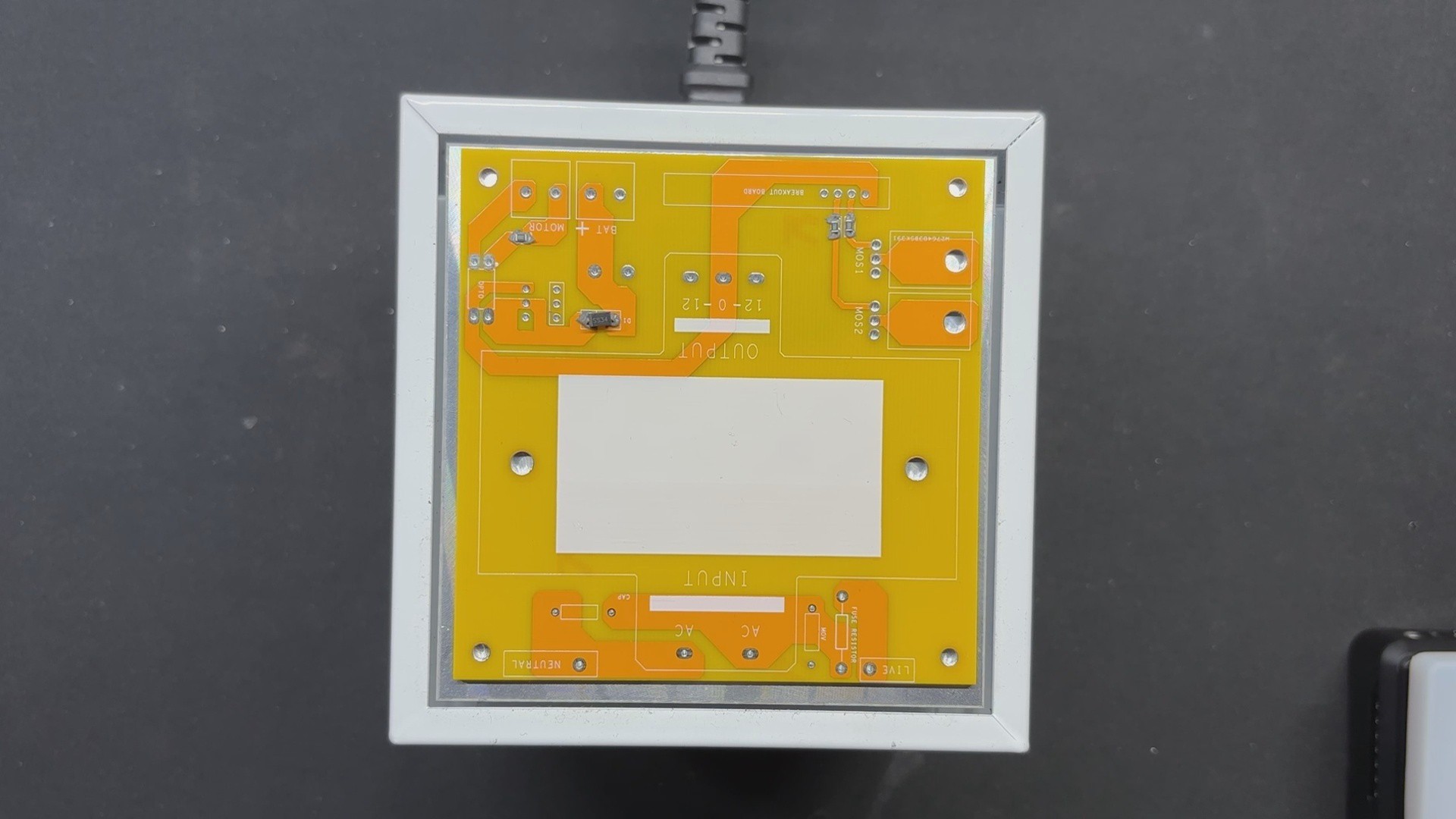

We created two PCBs for this project: the CD4047 driver and the MOSFET board. Two orders were placed, one for the CD4047 driver and one for the MOSFET board.

The CD4047 Driver Board was ordered with black solder mask and white silkscreen, and the MOSFET Board was ordered with yellow solder mask and white silkscreen.

After placing the order, the PCBs were received within a week, and the PCB quality was pretty great.

Their commitment to quality and customer satisfaction has been unwavering, leading to significant growth and expansion.

Also, PCBWAY is organizing a PCB badge-making competition to mark their 11th anniversary, inviting designers and makers to showcase their creativity by designing badges that celebrate the company's legacy and envision a bold future. Participants must incorporate the elements "PCBWay" and the number "11" in their designs and can use PCB, PCB+SMT/THT, or PCB+3D printing techniques. Submissions can be posted in the comments, emailed, or shared on social media with the hashtag #PCBWay11BadgeContest.

Prizes include cash, PCBway coupons, and free prototyping services for all qualifying entries.

You guys can check out PCBWAY if you want great PCB service at an affordable rate.

Arnov Sharma

Arnov Sharma

Sagar 001

Sagar 001

hesam.moshiri

hesam.moshiri

DIY GUY Chris

DIY GUY Chris