Currently I am attaching a vacuum needle to the 4th stepper motor and designing the finger operated control board.

Control panel now has 2x L293E stepper motor controller chips controlling 2 stepper motors. The circuit works but may need snobbery diodes and filter capacitors to operate reliably - the motors vibrate slightly (this was actually solved by oversampling by about x100 in the Arduino code).

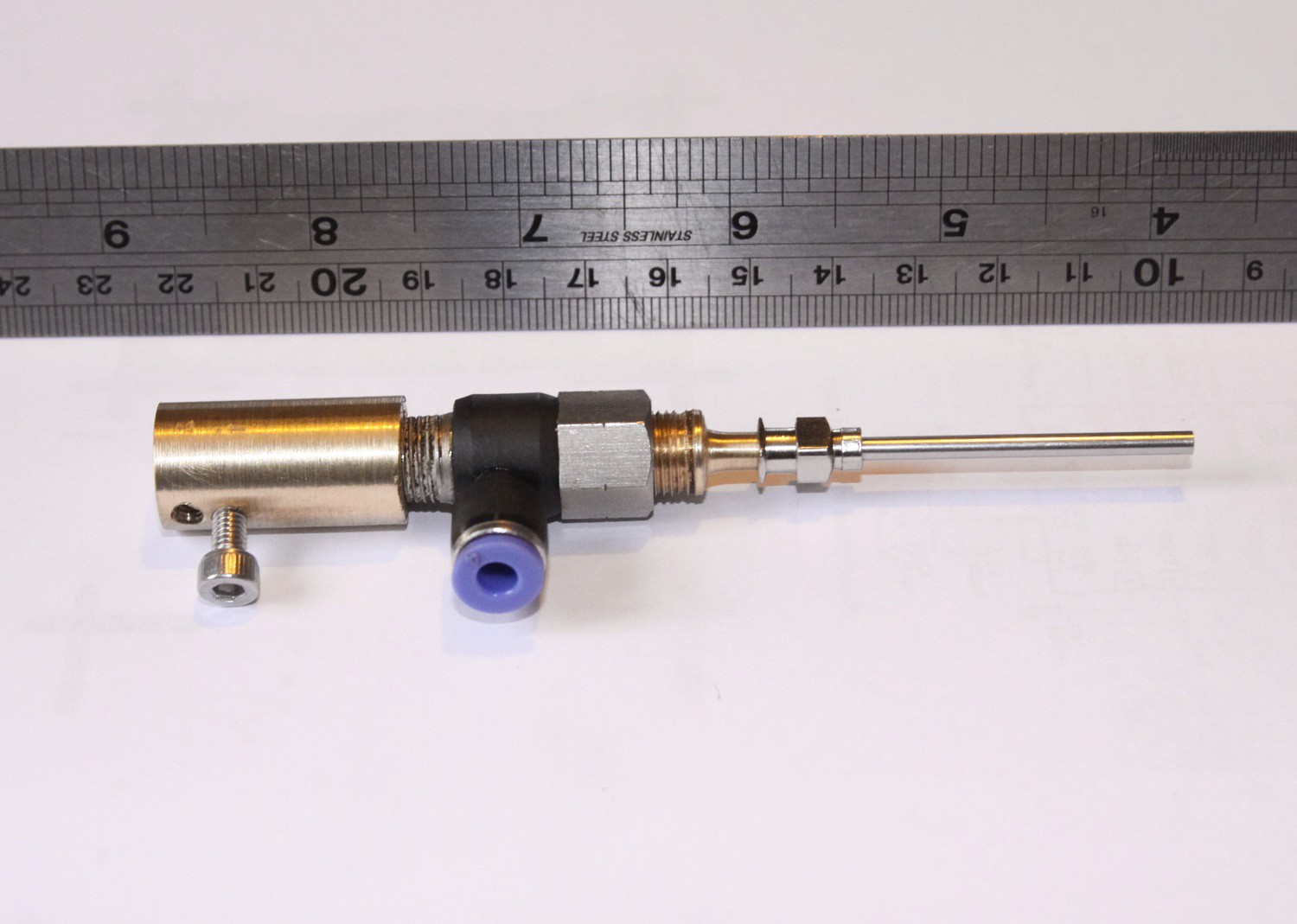

The vacuum needle system has been fabricated with two brass fittings made by my own hands on a lathe (see photo). It uses a special air fitting that has a rotating stem on a static banjo: 4MM X 1/8" NPT FEMALE SINGLE BANJO, Kelm One Touch Plastic Push-in Fittings. A standard T fitting would not work as the pipe would get tangled up in the machine as the needle revolves.

The whole machine needs to be extended upwards by about 60mm so some extra lengths of 2020 aluminium profile have been ordered. In the meantime, the control board needs to be hardwired onto proper PCB - Too many diodes and general breadboard frenzy has meant too many chances of shorts/bad connections. No worries though - I have space Hackable Prototyping PCBs just for this kind of situation :)

GOAT INDUSTRIES

GOAT INDUSTRIES

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.