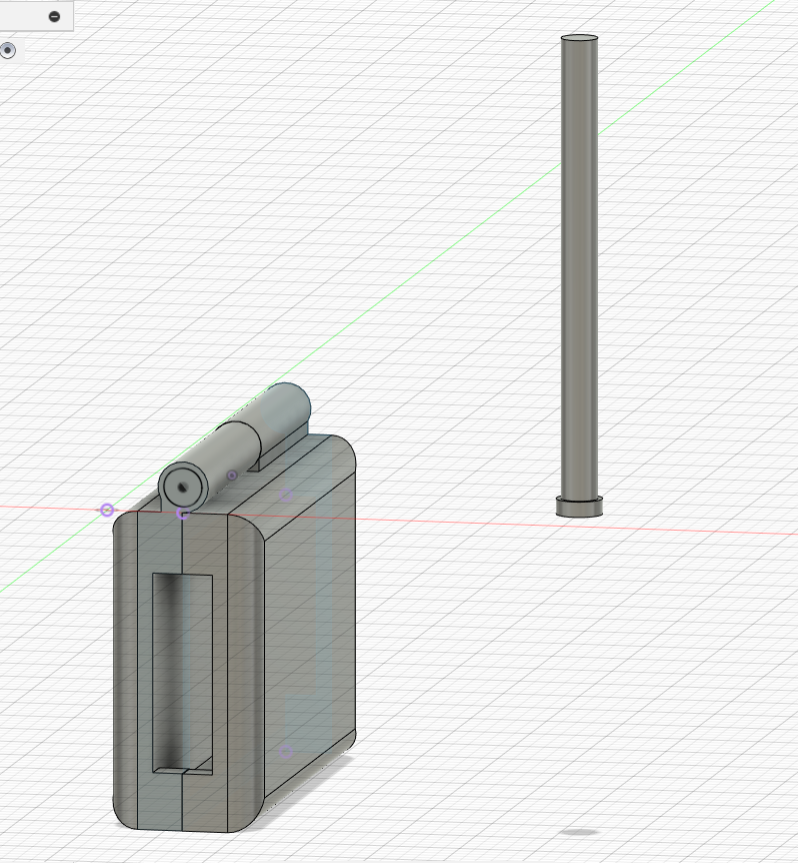

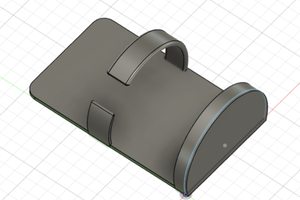

We met Diego who is a 12 year old kid with a malformation in his left hand. After discussing a bit with him, we decided to try to make an object to help him tie his shoes. Then, we came up with an idea, which is to create a clip that will hold the laces in place and also allow him to tighten his laces. We got the inspiration from multiple objects such as; plastic boxes and bracelet clips.

Project To Simplify Tying Shoelaces

This project aims to make tying shoelaces easier. The target users are disabled people with hand deformities.

nurdamla

nurdamla

aurelie.pavy

aurelie.pavy

Audrey Robinel

Audrey Robinel

Scott

Scott