First - this project is totally open source, and is available for usage by anyone who cares to do so in the manner of their choosing. I'll be posting the code when I get it written, and that will also be open source.

OK, a few details. There are a few parts to this puzzle. The first is the physical side - i.e. the structure of the kiln. The second is the electrical side - i.e. the controls. The final part is running/operating the kiln. I'll devote a section to each.

**STRUCTURE**

If you go to Home Depot, Costco, or any other 'Big Box', chances are you've seen pallet rack. It's made up of vertical standards with long beams in between and wire racks between the beams to put things on. What I discovered is that there is a healthy market for this stuff; used or new, buying or selling. In many cases, a pallet rack merchant will buy the racks from an entire warehouse that is being cleared out, and chances are, there are a few standards that aren't as pristine as they'd like them to be. If you can get one to answer the phone (not as easy as you'd think), a vendor will probably sell you a few standards for cheap if you're not stuck on looks. I was able to pick up two standards that had been twisted at the top as well as some new beams and a few wire racks. I drove them home, and promptly set to work. I cut the standards apart entirely with my sawzall and removed the cross braces. I also cut off the tops (I didn't need that part) so the standards were the height I wanted them to be. My end goal for this kiln was to have the wood drying underneath, and have a work bench on the top. I then shortened the cross braces (they were set for 42" deep and I wanted 30" based on my shop size) and bolted them back to the standards. Putting it all together (the wire racks had to be cut as well), and I had the structure in place.

In the pictures, you'll see that I then cut 1/2" insulation boards to contain the space. I used several rolls of aluminum tape to seal gaps in the insulation. This is the structure - modified pallet rack for the exoskeleton and insulation board for the skin. I'll also add some sheet metal to protect the insulation from getting banged up on the front and sides.

**ELECTRICAL/CONTROL**

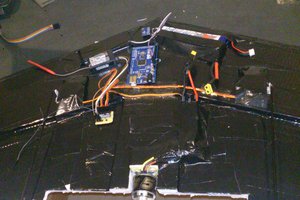

I am not ashamed to admit that I leaned heavily on the Arduino ecosystem to make this work. I am in no way an electrical engineer, and using an Arduino is stretching my capabilities as it is. Apology (or lack thereof) aside, my objectives for the kiln control system were:

1 - control of a dehumidifier (on/off)

2 - control of a fan (on/off)

3 - reading temperature and humidity inside the kiln

4 - logging data for temp and humidity

5 - displaying status on an LCD

6 – setting a target humidity level inside the kiln

7 - ideally posting status to the web

Based on these requirements, I utilized the following:

1 – An Arduino Duemilanove

2 – An Ethernet shield

3 – An LCD shield

4 – A DHT22 temp/humidity sensor

5 – A DS1302 Real Time Clock

6 – A relay board

7 – Three momentary buttons

8 – Jumper wires, some multi-conductor cable, other electronics stuff

The only real challenge associated with this setup was the number of pins required to make it work. Given that I hadn’t ruled out connecting a computer to the Arduino and reading data that way, I was down to 18 pins. If you add up the required number of pins to make things work, you arrive at the fact that I need 21 pins available. To get around that, I wired up the momentary buttons into a single analog pin and used resistors to make allow the board to differentiate which button was being pushed. Other than that minor improvisation, everything else was connected via jumpers and turned on. You might note that I didn’t stack the Ethernet and LCD shields together. That happened for three reasons. First, I like seeing the blinking lights on each board. Second, both of the boards want to use pin 4; to get around this, I ran one of the jumpers from the Arduino pin 3 into the LCD input on pin 4 and called out pin 3 in the code for the...

Read more » Tim White

Tim White

cb22

cb22

justin

justin

John Duffy

John Duffy

eric

eric

Hello, is this where a longtime project? Is it still going? Or you left this project with not all features that you thought to implement. I'm interested in this project.