Eventually, after revisiting the literature, I found another sensor, the PNI RM3100 (a bit more expensive, ~€30 on AliExpress), characterized by:

✅ very low thermal drift,

✅ very low pink noise,

✅ and, most importantly, a native RMS noise of just 13 nT.

And that reignited the project!

Here’s my plan:

1️⃣ Still use the statistical approach: 1,000 measurements → noise reduced to about 0.4 nT.

2️⃣ Rotate the sensor around the (1,1,1) axis to eliminate internal biases.

3️⃣ Design a waterproof, robust enclosure capable of long-term outdoor measurements.

For points 1 and 2, I plan to implement data fusion with a Kalman filter directly embedded in the microcontroller, like I had already done in this Hackaday project.

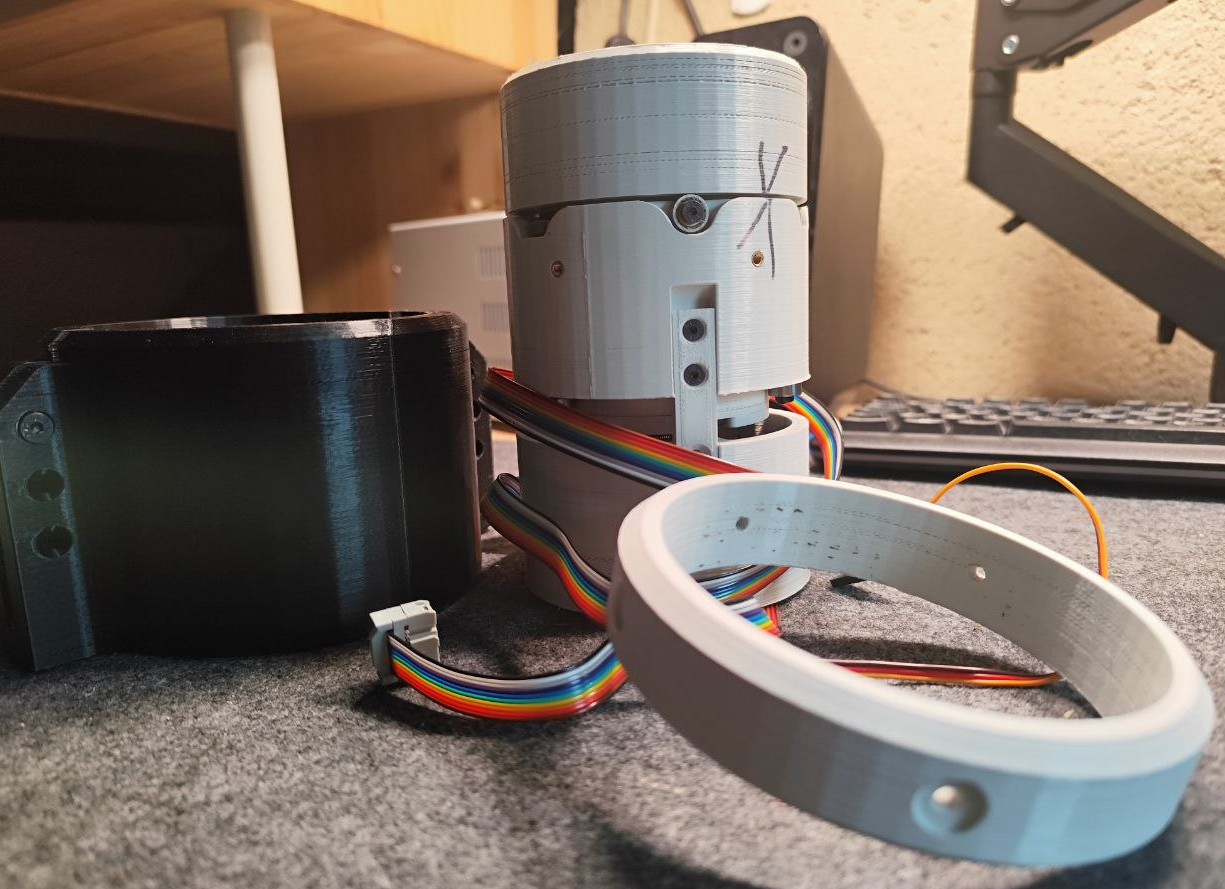

Current Status: CAD and Mechanics

I’ve already purchased the sensor (not yet received) and completed the CAD for the mechanical parts.

The setup is designed to fit inside a 100 mm diameter wastewater pipe, offering both waterproofing and low cost.

Instead of NEMA17 motors (which generate too much magnetic disturbance due to their strong permanent magnets), I chose a GM995 servo, much smaller.

I also took care to minimize metallic parts in the assembly. Remaining metallic components include:

-

small 623ZZ bearings (to relieve the servo and ensure guided rotation),

-

and some metallic screws, but fixed relative to the frame (thus creating a static, acceptable perturbation).

Bertrand Selva

Bertrand Selva

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.