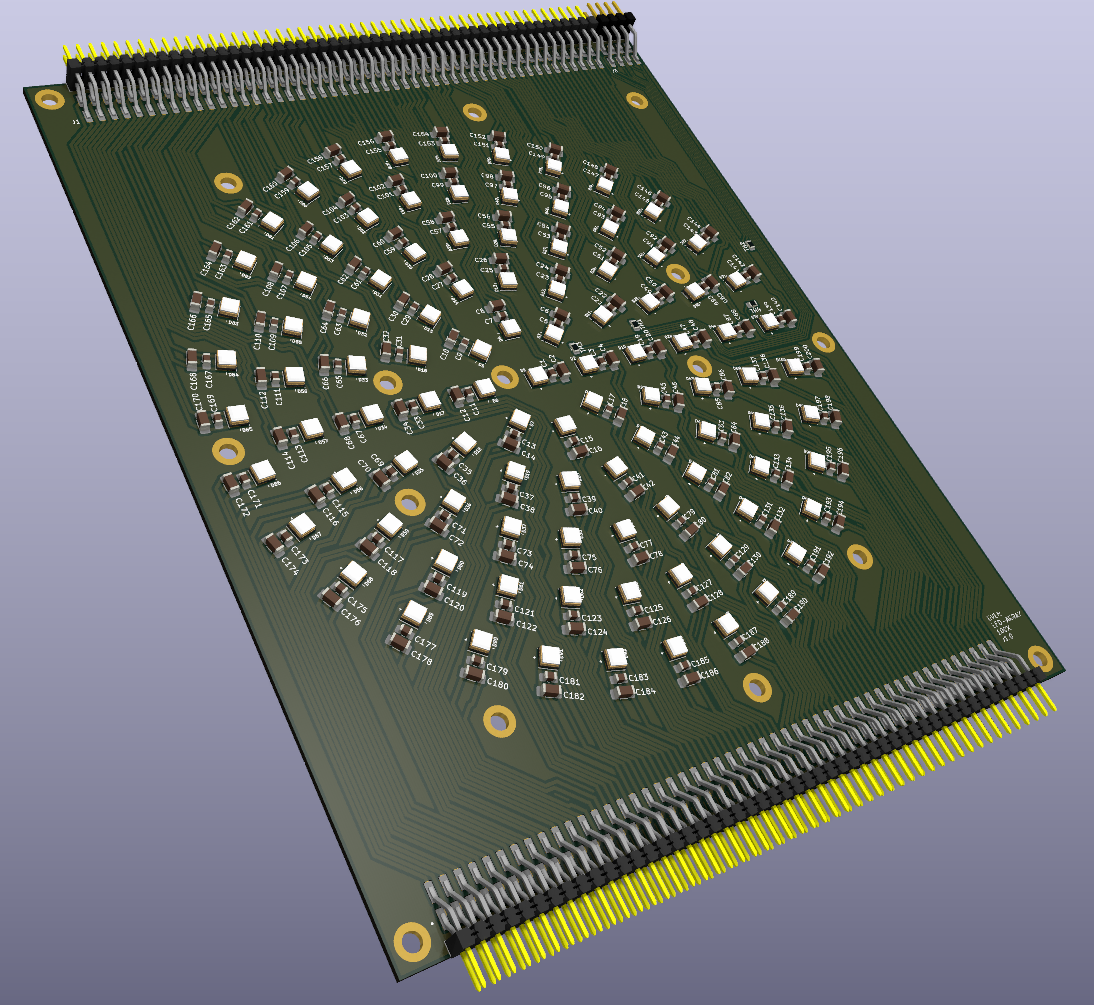

Next I designed the LED panel. We chose 100x LEDs for this version. The spacing is as uniform as possible. Unfortunately EasyEDA doesn't seem to have any way of positioning components in a programmatic way, so for this PCB I'm using KiCAD again. KiCAD has a python scripting console and I used the following script to place all the components automatically.

import math

import pcbnew

board = pcbnew.GetBoard()

# Ring configuration

rings = {

0: 1,

1: 8,

2: 14,

3: 20,

4: 26,

5: 31

}

ring_spacing_mm = 12

cap_spacing_mm_1 = 3.5

cap_spacing_mm_2 = 2.6

center_x_mm = 100

center_y_mm = 111

ref_offset_mm = 1.5 # tangential offset

def mm_to_nm(val):

return int(val * 1_000_000)

center = pcbnew.VECTOR2I(mm_to_nm(center_x_mm), mm_to_nm(center_y_mm))

ref_counter = 1

for ring_index, led_count in rings.items():

radius_mm = ring_index * ring_spacing_mm

for i in range(led_count):

angle_rad = -2 * math.pi * i / led_count

angle_deg = -math.degrees(angle_rad)

dx = math.cos(angle_rad)

dy = math.sin(angle_rad)

tangent_dx = -dy

tangent_dy = dx

# LED

led_ref = f"D{ref_counter}"

r_led = radius_mm

led_pos = pcbnew.VECTOR2I(

center.x + mm_to_nm(r_led * dx),

center.y + mm_to_nm(r_led * dy)

)

led_fp = board.FindFootprintByReference(led_ref)

if led_fp:

led_fp.SetPosition(led_pos)

led_fp.SetOrientationDegrees(angle_deg - 90)

c1_txt = c1_fp.Reference()

c1_txt.SetVisible(True)

c1_txt.SetTextAngleDegrees(0)

c1_txt.SetPosition(pcbnew.VECTOR2I(

c1_pos.x + mm_to_nm(0),

c1_pos.y + mm_to_nm(0)

))

# Capacitor 1

c1_ref = f"C{2 * (ref_counter - 1) + 1}"

r_c1 = r_led + cap_spacing_mm_1

c1_pos = pcbnew.VECTOR2I(

center.x + mm_to_nm(r_c1 * dx),

center.y + mm_to_nm(r_c1 * dy)

)

c1_fp = board.FindFootprintByReference(c1_ref)

if c1_fp:

c1_fp.SetPosition(c1_pos)

c1_fp.SetOrientationDegrees(angle_deg + 90)

c1_txt = c1_fp.Reference()

c1_txt.SetVisible(True)

c1_txt.SetTextAngleDegrees(0)

c1_txt.SetPosition(pcbnew.VECTOR2I(

c1_pos.x + mm_to_nm(0),

c1_pos.y + mm_to_nm(0)

))

# Capacitor 2

c2_ref = f"C{2 * (ref_counter - 1) + 2}"

r_c2 = r_c1 + cap_spacing_mm_2

c2_pos = pcbnew.VECTOR2I(

center.x + mm_to_nm(r_c2 * dx),

center.y + mm_to_nm(r_c2 * dy)

)

c2_fp = board.FindFootprintByReference(c2_ref)

if c2_fp:

c2_fp.SetPosition(c2_pos)

c2_fp.SetOrientationDegrees(angle_deg + 90)

c2_txt = c2_fp.Reference()

c2_txt.SetVisible(True)

c2_txt.SetTextAngleDegrees(0)

c2_txt.SetPosition(pcbnew.VECTOR2I(

c2_pos.x + mm_to_nm(0),

c2_pos.y + mm_to_nm(0)

))

ref_counter += 1

pcbnew.Refresh()

board.Save(board.GetFileName())

print("✅ Components and reference labels updated with tangential offsets.")

Routing was a bit tricky, because for a copper base board you can only route on the top of the board. I included 4 NTC thermistors as well, so we can get feedback on the LED temperature.

The LED driver boards will be connected on either side of the LED panel using the 2.54mm pin headers.

Simon Trendel

Simon Trendel

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.