There were two main approaches I could take:

Option 1: Hijack the Capacitive Buttons

This involves adding electronics that take over the touch buttons. Since the device behaves autonomously (e.g., it automatically switches off after sitting at power level 0 for a while), I’d also need to read all the LEDs—including the 7-segment display—to monitor its current state and react accordingly.

Pros:

-

Straightforward—no need to reverse-engineer the communication protocol

-

Built-in safety features remain fully active

-

The display still shows the current power level

Cons:

-

Requires careful tuning to reliably trigger the touch sensors

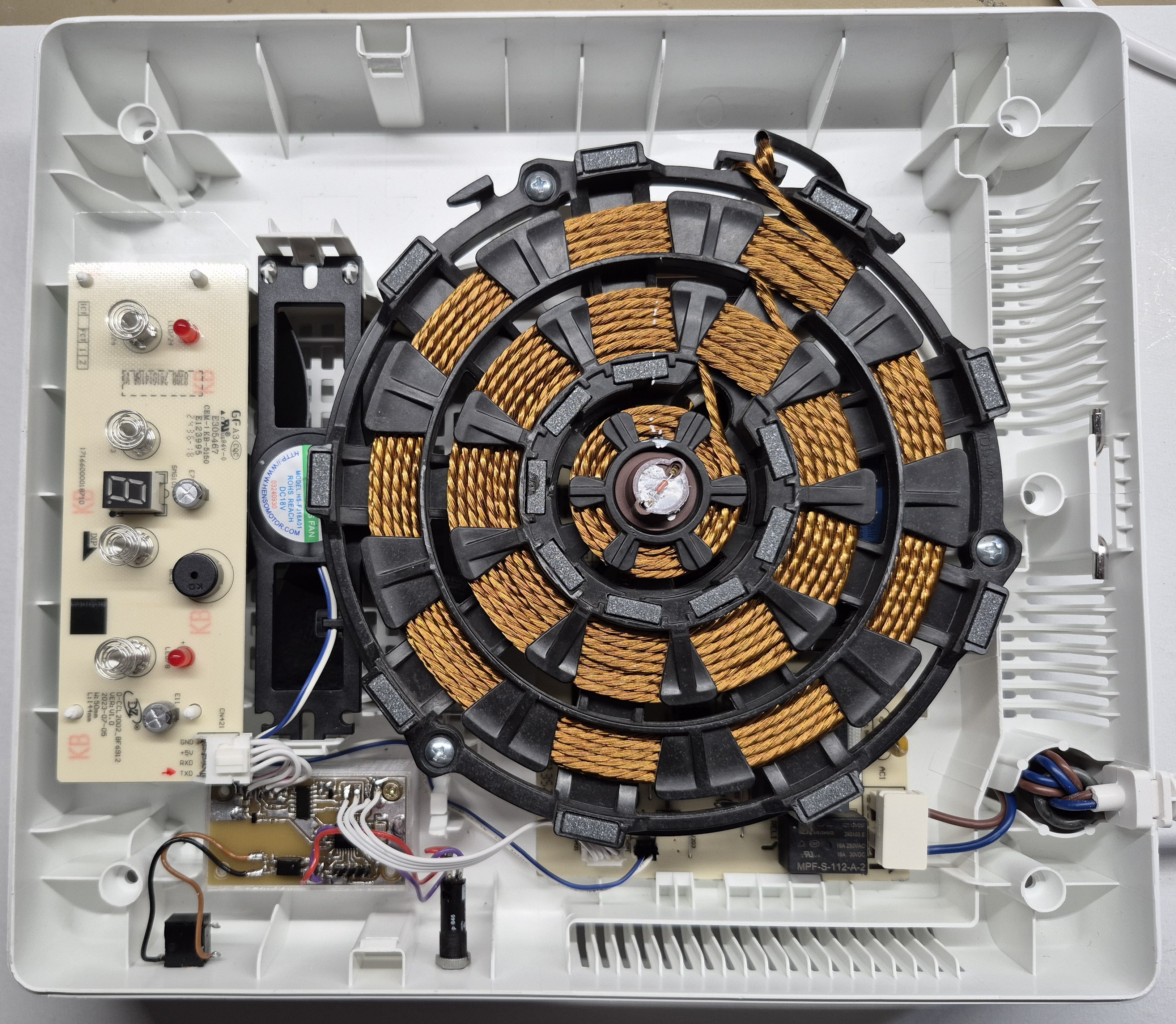

Option 2: Intercept the Communication Between Control and Power Boards

This means placing a microcontroller between the control PCB and the power PCB. It can pass through normal communication during manual use, and take over when automated PWM control is needed.

Pros:

-

Offers more direct and flexible control

-

Potential for finer-grained control beyond the default 0–9 power levels

Cons:

-

Requires reverse-engineering the communication protocol

-

Need to fully understand the built-in protection mechanisms

At the time, Option 2 seemed the most promising—or at least, the most fun from an electronics perspective—so I went with that.

Here’s a photo of the final working setup. More details to follow!

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.