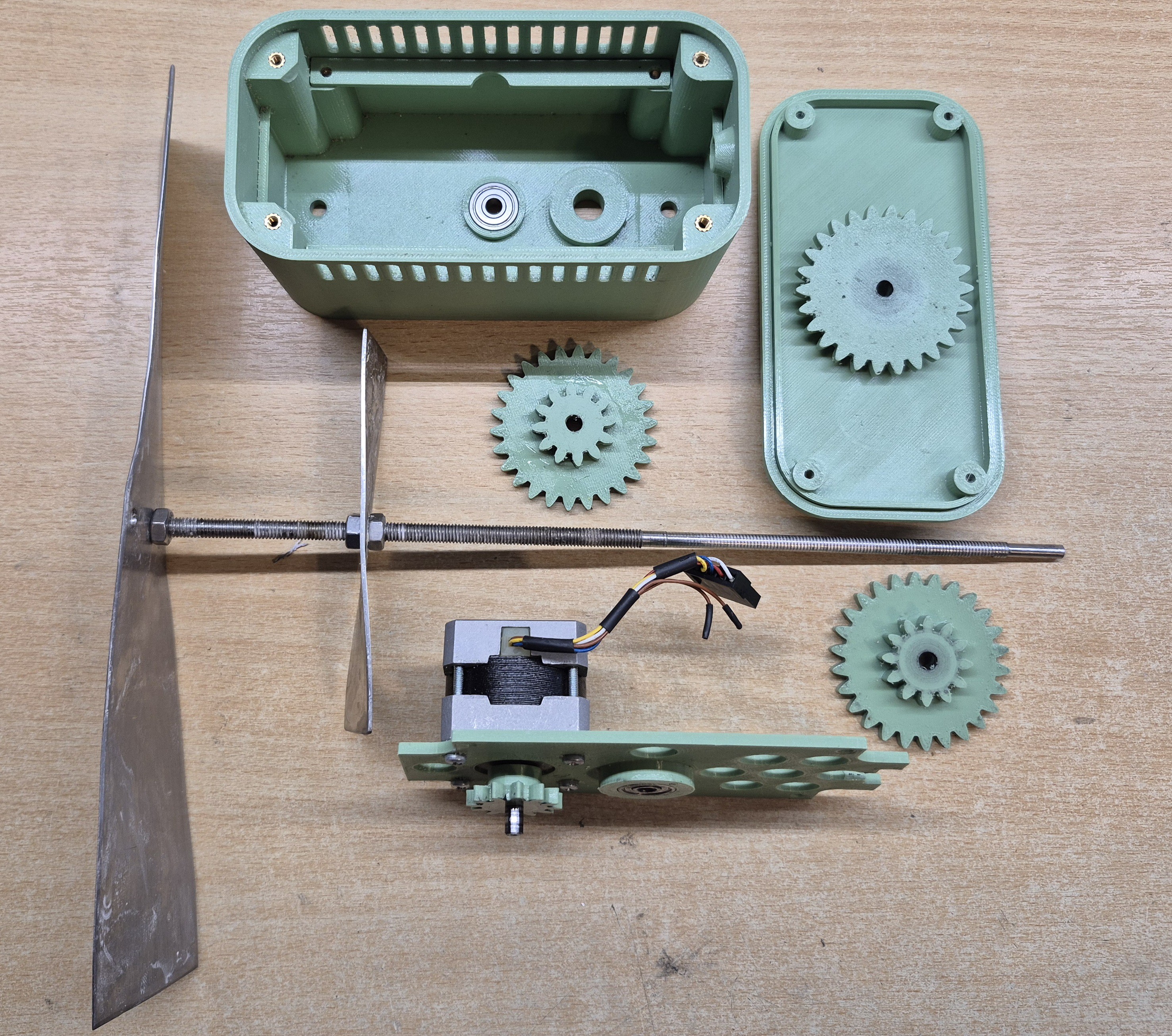

I started with a stepper motor paired with a 1:10 reduction gear to drive the stirring mechanism. However, I underestimated the resistance of the mash—it turned out to be too thick and heavy. The stepper motor just didn’t have enough torque to spin the stirrer at a decent speed. It managed around 20 RPM, which worked, but I wasn’t happy with the resulting temperature differences in the pot (up to 5°C) due to insufficient mixing.

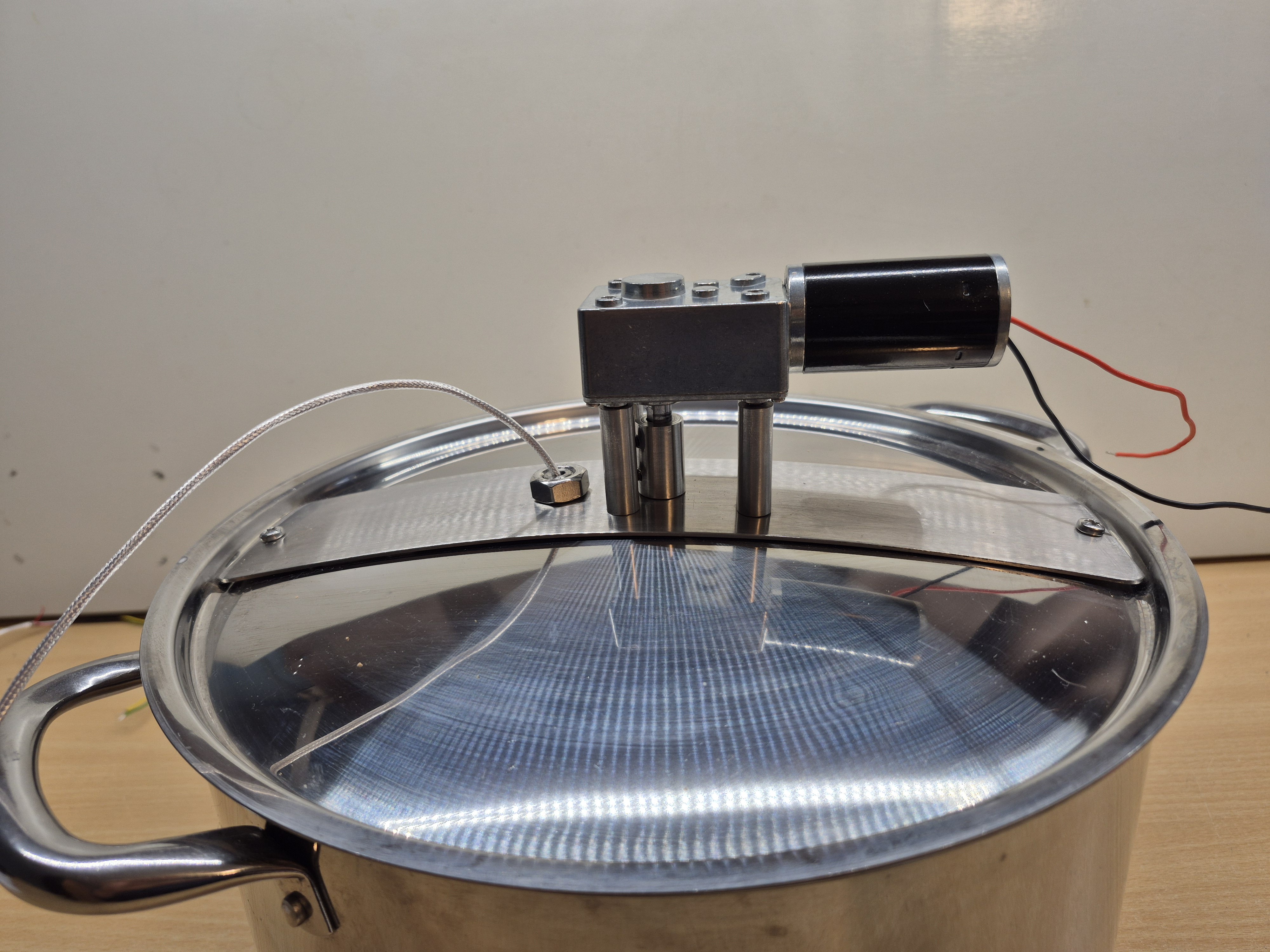

Next, I tried using a cheap battery-powered screwdriver, mounted on top of the lid with stainless steel supports. This motor had plenty of power, and the integrated chuck was convenient—it eliminated the need for extra bearings. Unfortunately, the minimum speed was too high for proper stirring, so I had to abandon that solution too.

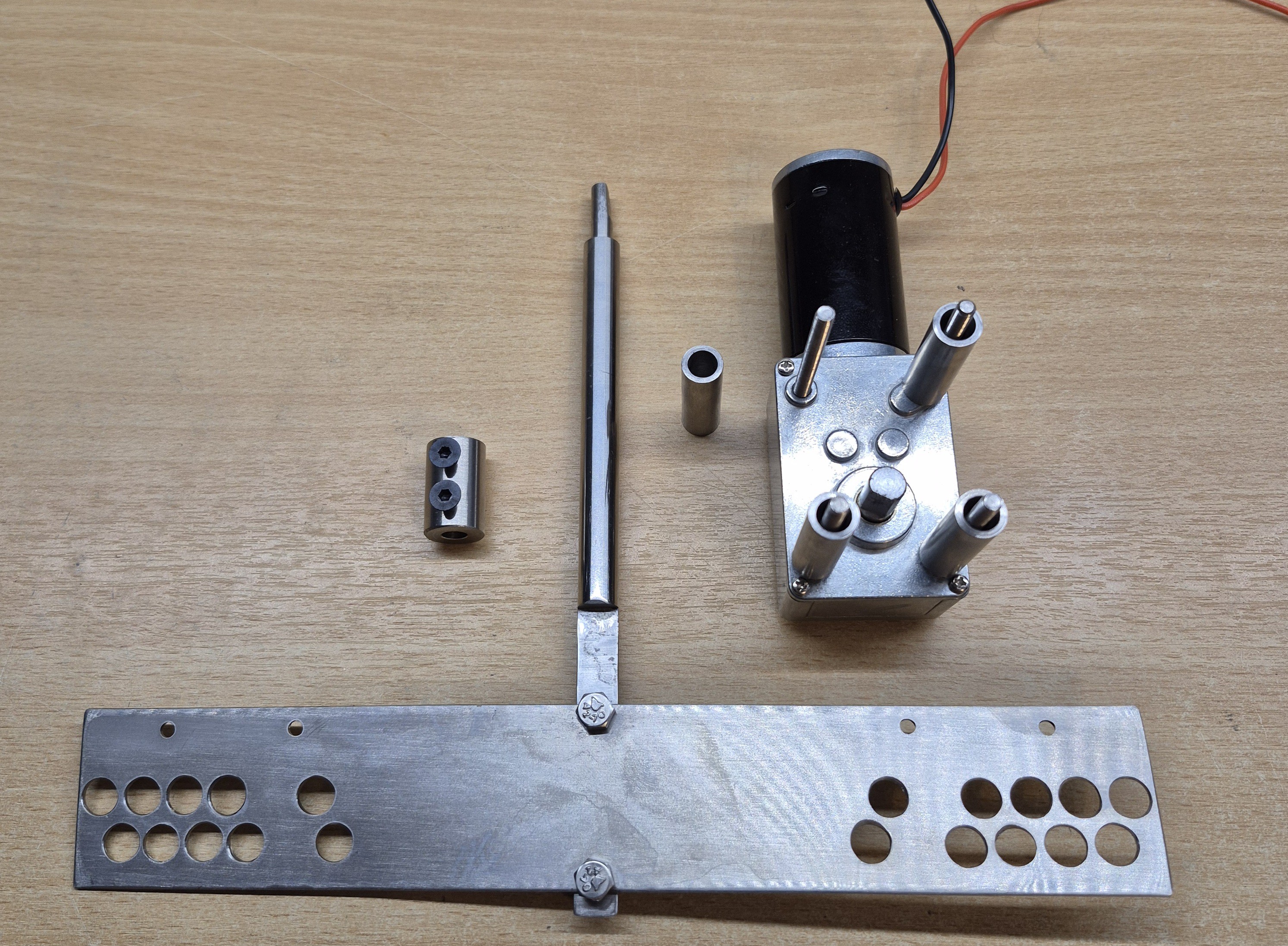

Eventually, I looked for a DC motor with an integrated gearbox, and found one on Amazon. I’m very happy with it—it’s quiet, powerful, and fits the job perfectly. I chose the 24V 100 RPM model, but if I were to do it again, I’d probably go for the 50 RPM version for its higher starting torque, which would be more than fast enough for this use case.

Using my lathe and benchtop milling machine, I machined:

-

A coupler to connect the motor to the stirrer shaft

-

A stainless steel shaft with a flat edge for securing the blade

4 studs to mount the motor

For the stirring blade, I experimented a bit. I added large holes to reduce drag and improve mixing. The blades are tilted at 10° to promote vertical flow. I also drilled small holes near the top so I can later attach extra surface area if needed, to improve flow across the entire volume.

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.