A USB 2 + Battery Conversion Mod easily applicable to any modern android phone!

PhoneBlox

A Old Phone Concept Brought Back To Open-Source Life!

A Old Phone Concept Brought Back To Open-Source Life!

To make the experience fit your profile, pick a username and tell us what interests you.

We found and based on your interests.

A USB 2 + Battery Conversion Mod easily applicable to any modern android phone!

Phoneblox housing all together model.f3zf3z - 19.80 MB - 07/30/2025 at 17:35 |

|

|

Phoneblox Power Button.stlStandard Tesselated Geometry - 25.67 kB - 07/30/2025 at 17:35 |

|

|

Phoneblox middle shell.stlStandard Tesselated Geometry - 78.60 kB - 07/30/2025 at 17:35 |

|

|

Gerber_S10-PoGo-Pin_PCB_S10-PoGo-Pin_5_2025-07-24.zipZip Archive - 7.17 kB - 07/30/2025 at 17:35 |

|

|

Phoneblox Back Panel.stlStandard Tesselated Geometry - 226.35 kB - 07/30/2025 at 17:35 |

|

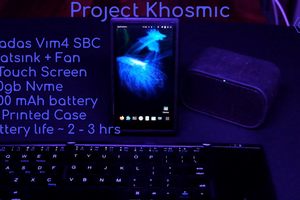

How to make your own Phoneblox!

Hello! This is my guide on how to make a phoneblox. This is all open source, and if you do make one, I would love if you would tag me on bluesky! My account is linked to my channel. Please keep all watermarks of the channel if you use any of the provided files! Again, I would love to see your work, so please, tag me!

Thanks to JLCPCB for providing me with the boards in the video! Get 3D-Printed parts, custom circuit boards and more at jlcpcb.com!

I was NOT told to say this, but JLC PCB provides AMAZING quality. Seriously, if you want to get something from them, you should.

NOTE

I am not responsible for any further damage done to your device. This is a risky process. Only continue if you really know what you are doing. Make sure you are in a well ventilated area while soldering, glueing or anything similar. Keep safety first and wear all protective gear. Make sure you are ready for the possible chance of destroying the phone, as it isn't easy.

And again, I am not responsible for any further damage, to your phone, or yourself.

You have been warned.

ANOTHER WARNING

I am very bad at board modelling and F360, so to pros, this will prob seem very badly made. Feel free to show and share me your redesigns, at bi0sbootmedia@gmail.com and I may provide a link to it in this document!

NOTE 5;

As you saw in the video, the battery boards, I DID NOT order them, so I have no proper way to know if they work. If you are planning to do the battery method, (Which I dont reccomend) Buy at your own risk.

Good Luck And Enjoy!

-----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

What you need:

Donor phone

Soldering iron

Solder

3D-Printer (Or anything to make the housing out of)

Patience!

CAD skills (im awful at it and i could do it so if you arent the best it is very minimal so :p )

Gerber editing skills

Heat Gun - If you are using the battery boards

Step 1)

Selecting a phone

For the phone, I wouldn't go with an iphone. USB 2 will be used frequently throughout the setup and iphones don't really handle accessories well, so go with an android. Any android will do, although I would recommend a phone that is fully flat and that you can take the screen apart. For example, I'm using a samsung galaxy S10, which has a curved display, so i have to revolve a shell around it.

For the phone specs, it really depends on what you want. If you just want to do calls, any budget phone from the past 5-8 years will work fine. If you want to do more intensive tasks like gaming, you should use a mid to high end phone from the past 5 years.

Models i would recommend are;

Samsung Galaxy S10 - S25

Google Pixel 5 - 9

Fairphone 4 - 5

Any phone that you have will work, as long as it supports USB accessories. I would recommend a phone with a desktop environment like samsung dex, if yours doesn't have it, you can use a third party launcher on the Play Store.

2) Boards

For the board, (where everything will attach) you need to figure out what you will be removing. For example, I'm doing a;

Battery

USB 2

Speakers

EDIT-

This is me from the future, I realised that the battery has more than just positive and negative connectors, as you saw in the video, so I didn't do the speaker, so make sure you know what all the pins do in the battery, speaker, etc.

It's not a lot, but the usb 2 will use accessories like thermal cams, etc. I have the board file, which I think is pretty modular across all phone types. You will need to solder though. The setup for usb is complicated but this is how it will work.

The charging port can be mounted at the bottom while you can cut the wire for the USB 2 board and solder it.

For the components, I am using 0.8mm pogo pins from aliexpress. I have 10 rows of 8 pins in each “cluster”, so I will need at least 80 pins.

Here is where i went wrong when writing this.

DO NOT, and I repeat, DO NOT, solder the pins to the base board itself. It was a moment where my brain was not in gear as if you solder only what you need to the blocks, you will only end up doing a fraction what that was. For example if I do one USB 2 Device, and One Battery, that ends up being only 8 pins I have to solder. So just hear me out, Make the pins pads on the main board, and solder the pogo pins to the bloks.

For the components themselves, I will add pads into the PCB software “EASYEDA.com” for connection to the board to the component. This is where you need soldering and PCB editing skills. For the battery, you will need to replicate the connector on it as the pads are way too small to solder wires to. For example, this is a ribbon cable I designed to wire the battery connector to the board.

I will use a FPC ribbon board like this

Which then connects to a soldered on battery connector, and the ribbon cable goes to the main connector board, like this.

They will then go to where they respectively locate.

(i.e. Micro USB to USB C splitter, BAT FPC to the Bat connector, etc)

3)

Housing

I would recommend you 3d print it. You can model it down to the accuracy of the boards, and it is much more stable then any other option. If you do not have a 3d printer, I would recommend modeling the housing very precisely and if a library or friend has a 3d printer, test it on that first. You can then fabricate 3d models in JLCPCB when buying the boards and get a perfect finish. I use fusion 360, which is the standard across most hobbyist makers, but any similar software will work. Id recommend using f360, but definitely dont use anything like tinkercad. It isnt complex enough for this build.

For the final model, I am getting it made from Aluminum 6061 from JLCCNC3D to give it a quality more structured feel.

4)

Modelling the housing

When modelling, you have to account for these main components;

Motherboard

Display

Speakers

USB splitter

Back connector board

Etc.

You may have to trace the motherboard into the software if you do not own a scanner. For the screws, keep slots for small, heat set inserts, you can install these with any soldering iron and ensure a stable connection. For the bloks, you need to measure the exact size that it can line up with the other ones on the boards.

If you are using metal like I am, Insert the screw size in a thread in fusion or however you do in your said software.

For the volume buttons, you can make a crank and shaft style push button that rests on the button of the phone, or, you can make flex cables (from the best of the best at jlc) to actually have a contact. I was initially going to do this, although like i said, if you arent great at soldering, I would say to avoid it. I have made solderless boards linked below so you can use them if you want.

5)

Blok ideas (over usb 2)

Well done! You have completed the project. Here are some blox ideas for the phone;

USB hub

Flashlight

Thermal cam

USB storage

All of these can be easily modeled in the software EasyEDA, which has 2 modes, for pros and beginners, Which I highly recommend!

For connecting the bloks, I would make something like this for USB 2/BAT.

Like I said, Make sure your battery connector has the right amount of pins, or it wont work.

Thanks to David Hakkens for the original concept, and thanks for supporting me!

FILES -

Make sure to alter the position of the STL/F3Z of the phone shell to fit your printer.

This folder contains all the files necessary to build the phone.

https://drive.google.com/drive/folders/1-IgkQyCmx4CWKqMlsGnTF5DESIH8y76S?usp=sharing

And once again, Thanks!

Phoneblox Lite;

How to make your own Phoneblox Slim

What is phoneblox lite? -

Phoneblox lite is a rough concept idea from myself that has basically no effort into it, but is more of a idea. You can make your own model a case like adapter, or just replicate the original without the battery removed and re-wired

I would recommend doing this over the original phoneblox as it requires much less effort. You can interpret designs for the battery maybe through QI or wireless charging, or just through the usb port. It is much easier and gives the exact same result. The only thing you are missing out on is design, although for the work that it takes, this is much easier. As you saw in the video, I just used the original model but didnt bother with the battery cuz im awful at soldering.

Phoneblox lite is a phone-case adapter, which plugs into the usb c/microusb of the phone, which allows for battery add ons and USB 2 Pins. It contains the use case of the original main phoneblox but on a very tight budget. It allows you to make the phone without breaking the bank, and not having to go soldering.

What you need

Decent CAD Skills - Camera punctures, EASYEDA, etc

A phone, android preferred

Around $/€/£50, depends on how detailed your boards are, and what material you make it out of.

This project is minor, and will very unlikely be made by me. If I have spare time during the video, I will make it, although It is unlikely.

Step 1) Design the case

I would recommend finding a 3D model of the phone and indenting it into a very thin, small box onto your cad modeling software, and then print in a flexible material like tpu. This makes it so you can glue this mould into a full design. I would recommend you make the shell revolve around the phone as it makes it looks much nicer.

Step 2) Model the board

You will need to make a USB C board to ideally 4Pin FPC connector, as you can just rip the board files from the mail phoneblox drive (linked below) and resize it to however your phone needs it. I would recommend you properly make it fit right as you will have space for your camera.

What benefits and negatives is there to making the “Lite” Variant;

Cons;

Basically fully better than main phoneblox, other than flair factors.

I.e. The internal battery is still in the phone, So it breaks the illusion, but you can

Pros;

You get to Not solder, not have to worry about buying extra equipment, and is more of a fun weekend project.

You skip out on;

Making Battery Board

Soldering Battery Connector In block and in the phone

Complicated wiring setup, lots of areas of failure,

Cheaper total cost with same end function

Can be pretty universal, If you design correctly,

You could use it even as a external USB C hub

No extra tools to buy

From 5 Total PCBS to 3 (only inc. USB Block, BACK board, and type c to ribbon cable.)

The only real thing you are missing out on is bragging rights, but does it rlly matter? You have cool phone 🤷♂️

This is much more optimal, and will prob phase the original out in popularity. Its easier, cheaper and overall better. While I do plan to make this in the final video, budget may be tight.

Create an account to leave a comment. Already have an account? Log In.

Become a member to follow this project and never miss any updates

Srinivas Nistala

Srinivas Nistala

Conceptual Hardware

Conceptual Hardware

Ahmed Bilal

Ahmed Bilal

Badar Jahangir Kayani

Badar Jahangir Kayani