Why create this?

I started this project for two reasons,

I wanted to try object detection for cats

I was interested in seeing if I could use object detection to tell my cats apart, I already have thousands of pictures of them on my dslr and iphone so why not use that data set to my advantage.

The apps bundled with existing products aren't very nice to deal with:

At home we already have a automatic cat door by sure petcare so i could probably just have bought one from them. But in recent years, Ive been frustrated with opening their app and other smart home apps only to find that i have been logged out.

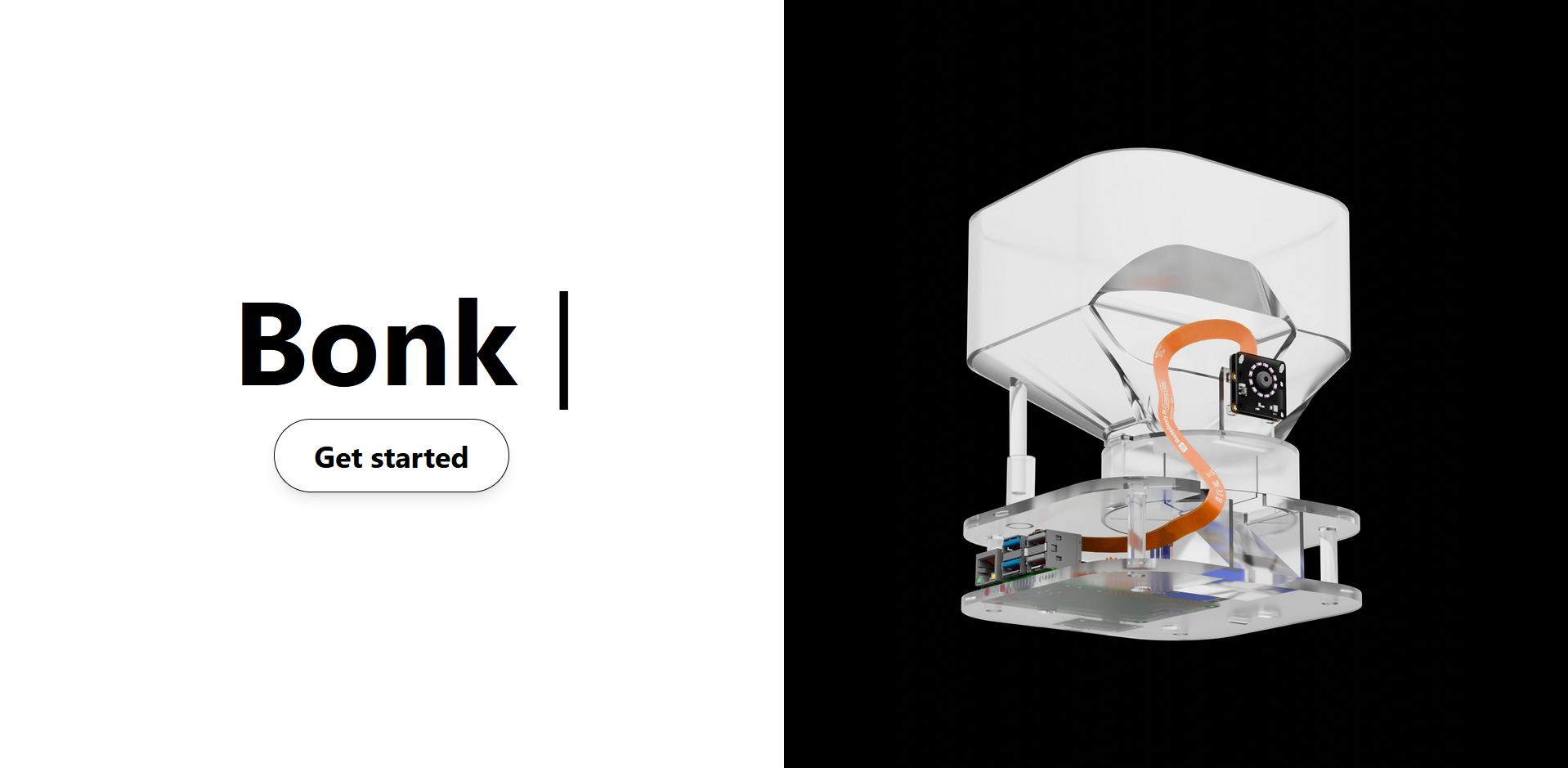

The design process

So this isn't my first attempt at building a cat feeder. A few years ago, I created a prototype using Arduino. In that first version, I used a simple rotating circular door mechanism. However, it came with several issues: food would often get stuck at the edge of the door, and the weight of the food could sometimes force it open.

Now in my second attempt i wanted to make something proper however i had no good ideas, i designed a sliding door, circle sector door and a square rotating door. Later on while scrolling on AliExpress i found a xray view style image of a cat feeder. It uses a rotating impeller to move food from the hopper to the outlet and into the bowl. This felt like the best solution so its the one i went with.

For the early concept renders, I started with a rough sketch of the design. Since gpt 4o image generation had just launched, I used it to bring the sketch to life, then refined the result in Photoshop. While the render looked good, it didnt account for internal components, so I used Blender to experiment with the layout. Blender isn't ideal for precise measurements, but its great for figuring out where i can place things.

Once I had a rough idea of where each component could go, I opened up Autodesk Inventor and started designing. The goal was to have a full assembly file so I could see how everything fit together before printing the parts. I went with a level based system, stacking 3d printed pieces to create different layers for the components, feeding system, and food storage. Things got complicated quickly, as some parts started interfering with each other. In the end, it wasn't as simple as just lifting off each modular section to take it apart.

Electronics

This is really a weak point for me, so i consulted my grandfather for help on how to to power the thing. I wanted to power everything using a single USB C cable, but that turned out to be tricky. I had read that you shouldn't connect servo power directly to the power rail on the Raspberry Pi 5, which made the setup more complicated. To solve this, I used a USB C breakout board and placed it between the Pi and the power source. From there, I connected a separate power and ground cable to supply the components. After my grandfather helped sketch out how everything should be wired, I ordered the parts from Amazon and a Swedish company called Electrokit.

I'm not very confident with soldering, so I used a mini breadboard to avoid it where possible. That said, some components like the ring light still needed to be soldered.

Putting it all together

I used a Bambu Lab A1 to print all the parts. A few pieces had to be reprinted due to alignment issues, but overall the process went smoothly since most of the design challenges were already solved in the assembly file. One thing I didn't account for was the camera cable, so I had to redesign that part to include a proper cutout.

Software and website

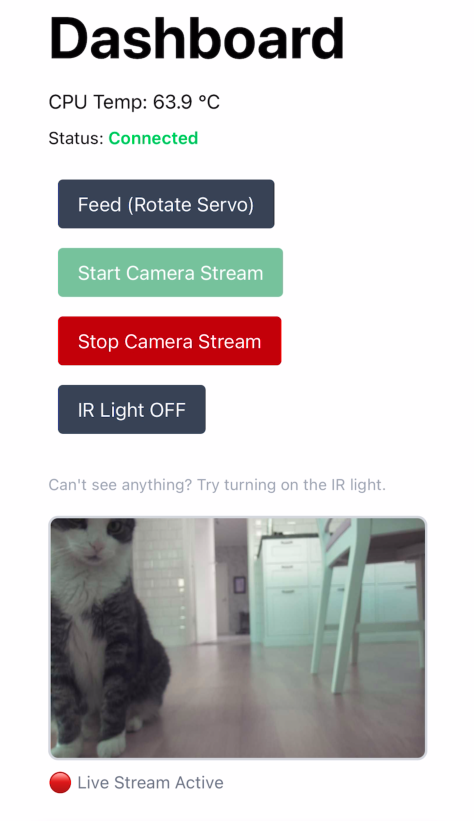

The entire website backend and frontend are hosted on a Raspberry Pi 5. The only hosting related cost is renting a DNS. The backend is written in python using the Flask library. It handles incoming network requests that control the hardware of the device like dispensing food or turning the ir light off. For the camera stream, I initially tried sending a network request for every frame, but this approach was inefficient. Switching to web sockets significantly improved performance, providing a much smoother stream with higher FPS. The frontend is written in Svelte, its a simple web page with just four buttons.

This is an ongoing project so i plan to add

- Feeding logs

- Feeding limits

- Scheduled feed times

- A more complete, well-rounded website

Object detection

I have an AMD GPU, which doesn’t usually play well with machine learning on Windows. While you can almost always fall back to using the CPU with libraries like PyTorch, it's far from ideal in terms of speed. Since CUDA is developed by NVIDIA and AMD's alternative (ROCm) wasn’t available for the version I needed on Windows, I took the harder route and installed Ubuntu in a dual boot setup. Realistically, just using the cpu would have been quicker but wheres the fun in that?

I used Roboflow to label 288 images then augmented them to generate more for the final dataset. I then trained a YOLOv11 model and exported the weights to the Raspberry Pi 5, where the model runs alongside the camera feed in the backend. The object detection runs a bit slow, typically over 100ms per frame, so I run the detection and camera stream on separate threads.

Integration with Apple Shortctus

For this, I chose the simple route. The shortcut just sends an empty post request to mydomain/api/feed, which in turn activates the feeder. I named the shortcut "Feed the cats," so I can trigger it using Siri on my phone or watch.

Reliability issues

Overheating

Recently, I’ve been experiencing random shutdowns, which I believe are caused by overheating. The webpage sometimes stops responding, and I noticed the temperature spike to 82°C one time before it happened. I'm currently using a passive cooler to reduce noise, but the current design does not have proper ventilation.

Food getting stuck

If there's too much food in the funnel, the individual pieces tend to jam by pressing against each other. I tried to fix this by adjusting the shape and size of the hole, but that wasn't enough. I also attempted to reduce the tension by installing a plastic rod in the center, but that didn’t work either. I think i knew these changes wouldn't be enough but a proper solution to this would be more difficult.

The project continues...

While the design has come a long way, there are still some reliability issues to solve. I have some ideas on how to fix them, but they require me to take apart the feeder and reprint a lot of parts. So I will keep moving forward, though probably not at the same pace as before.

While it can feel a bit demotivating when major issues start to stack up, it's still incredibly rewarding to build a product like this.

David Lockley

David Lockley