For affordability and adoption, scaling fiber circuit production is essential, as textile factories need long fiber spools.

Most FPCs are made on panels under one meter. For instance, LED strip reels are usually soldered by hand, meter by meter.

Extreme cost optimizations as for NFC tags use continuous processes such as roll-to-roll production. They unwind flexible material from a feed roll, go through steps like etching, printing, bonding, and coating, then rewind onto a take-up roll.

For yarn fabrication, similar continuous processes are employed, including spinning, and braiding.

Spinning involves twisting fibers together to create yarn or thread.

And braiding involves intertwining multiple strands to create yarns, laces or ropes.

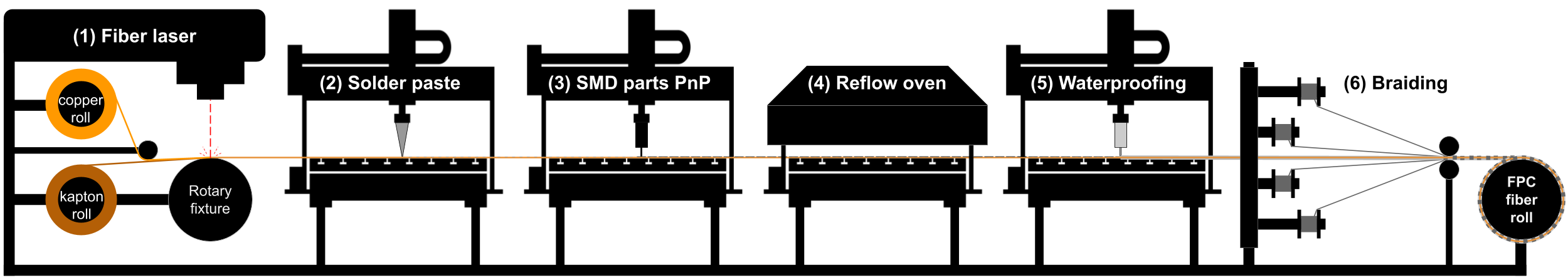

The paper details the six steps to continuously fabricate FiberCircuits in a roll-to-roll process:

Summary: with a minimal redundancy, we estimate that this FiberCircuits production line can run at about 2 km per hour. The set of machines needed for this continuous fabrication would cost from USD 12K to 52K, and the materials would cost about 10K to 50K per kilometer. In comparison to roll-to-roll lithography, exemplified by the LR2RC1500 platform, the process demonstrates approximately fivefold greater cost-efficiency and achieves operational speeds that are five times faster.

Cedric Honnet

Cedric Honnet

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.