Project Update – Big Progress Behind the Scenes 🚀

Sorry for the long gap since the last update — it’s been quiet on the outside, but a lot of exciting work has been happening behind the scenes. Development has been moving steadily, and this update is a good checkpoint to share where the Modular Micro‑PLC project is heading and what’s already been achieved.

Project Recap – Rethinking the Electronics Brick

At the core of this project is a simple but important idea: reverse the usual design logic of electronics sensor bricks.

Instead of starting with electronics first and then struggling to fit everything into a case, the design begins from a mechanical perspective:

- All components are designed to fit cleanly into an enclosure without extra mounting tricks

- No awkward brackets, spacers, or custom mechanical patches

- A more universal footprint, especially targeting DIN rail–mount enclosures

To support this philosophy, the project strongly focuses on a single-layer PCB approach wherever possible. This dramatically reduces mechanical complexity, keeps manufacturing simple, and makes enclosure design far more straightforward.

Hardware Status – Phase One Complete ✅

The PCB design and Phase One testing are now complete.

The core system is modularized into the following fundamental modules:

- Power Module – handling input regulation and system stability

- Simple Terminal Block Power Module

- USB Power Module

- Battery Charger Module

- MCU Module – the main control and processing unit

- ESP32 MCU module

- I/O Module – flexible digital input and output handling

- Digital Input/Digital N-MOSFET Output Module

- OLED/7 Segment Display Module

- Analog Input Module

- Weather Station Module

- Stepper Driver Module

- Communication Module – enabling expansion and connectivity options

- RS485 Module

Each module follows the same mechanical logic and can be combined without redesigning the enclosure every time.

Faster Development – New P2S Printer 🖨️

To speed things up on the prototyping side, I’ve brought in a new P2S 3D printer. This has already made a noticeable difference:

- Faster iteration of enclosure concepts

- Rapid validation of PCB-to-case fit

- More frequent mechanical tweaks without slowing down electronics work

This upgrade is playing a big role in keeping development momentum high.

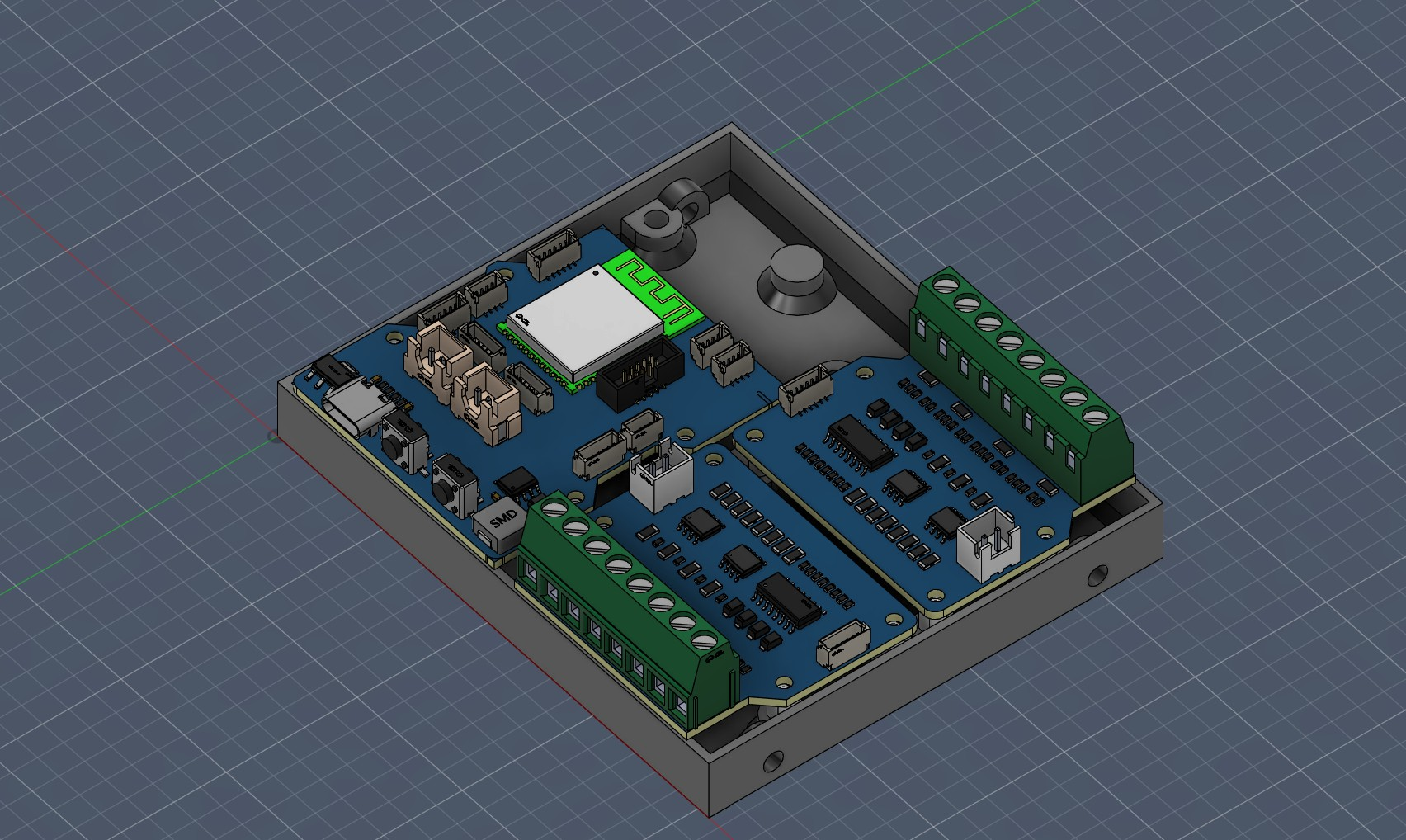

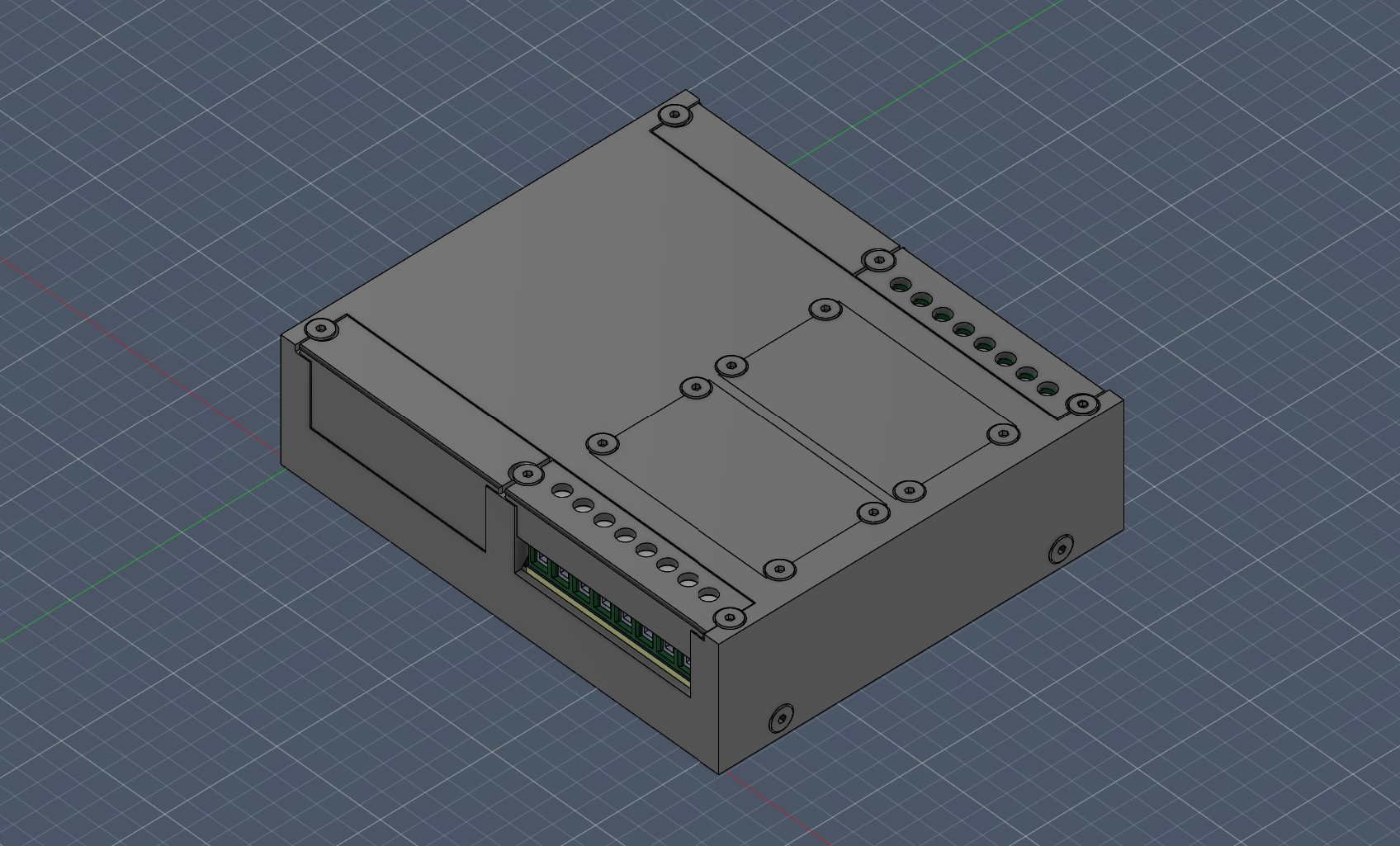

Updated Rendering – Assembly Details Revealed

A new rendering is now available, showing much more detail in the overall assembly:

- How the modules stack and align

- Wiring and connector relationships

- The mechanical harmony between PCB size and enclosure geometry

This better reflects the real-world assembly and helps visualize the full system rather than isolated boards.

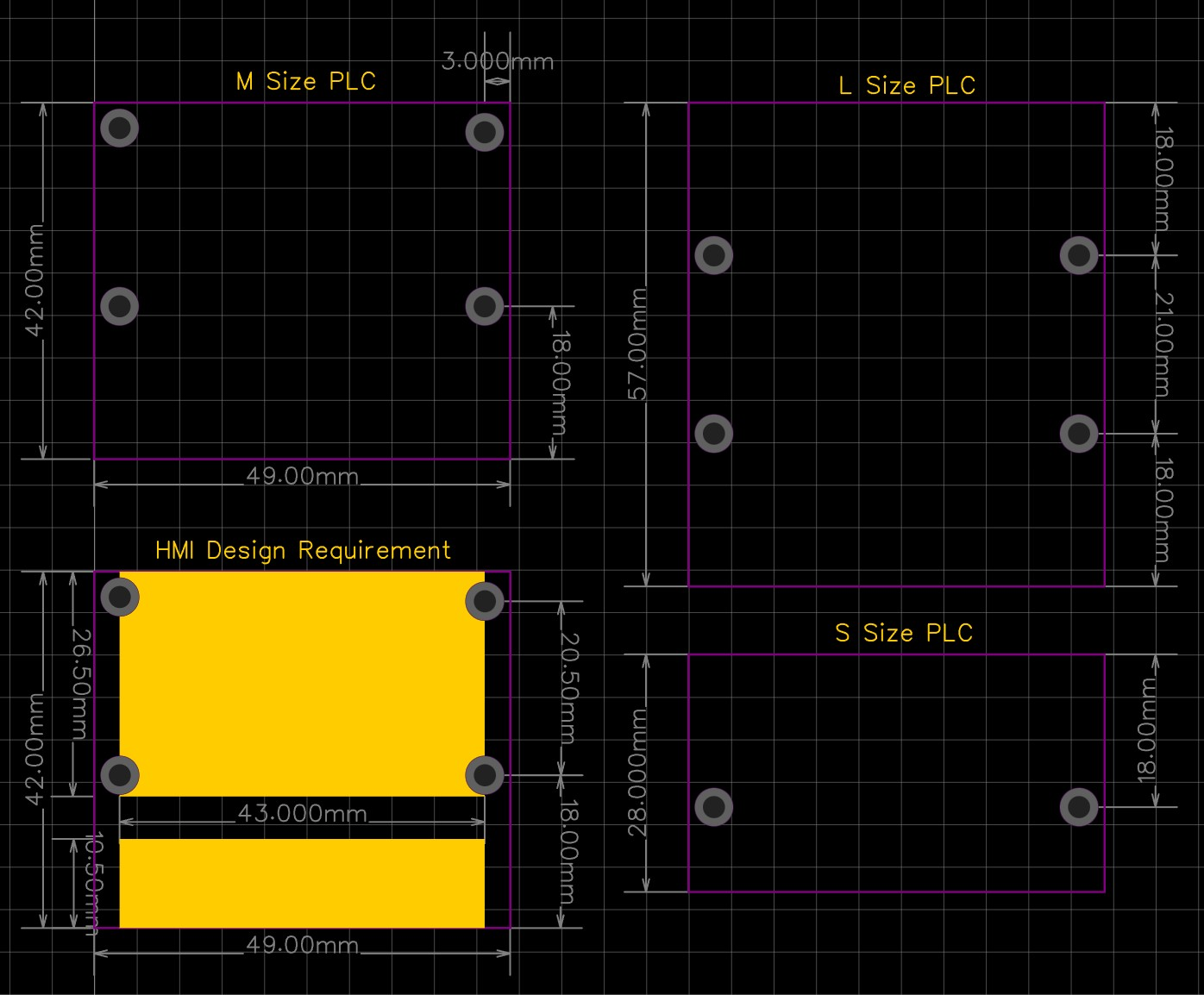

PCB Sizes Reworked – Small, Medium, and Large

One major refinement in this phase was reworking the dimensions of the PCB lineup.

There are now three standardized PCB sizes:

- Small

- Medium

- Large

All three sizes are designed to be intercollegiate, allowing them to mix and match within the same system. This makes the platform flexible enough to cover most application scenarios without forcing a custom board for every use case.

Upcoming Demos – Three Clear Goals 🎯

To better demonstrate what this platform can do, three main project demos have been defined:

- Weather Station A practical sensor-focused demo to highlight modular inputs and communication.

- OLED Clock Display A simple system using an OLED display with clock functionality — perfect for showing UI handling and low-power operation.

- Micro‑PLC Demo A more industrial-focused example featuring digital inputs and digital outputs, showcasing the platform as a compact, modular PLC solution.

These demos will help validate both the hardware and the mechanical design philosophy in real-world scenarios.

Thanks for sticking around despite the quiet period — more frequent updates are coming now that this foundation is in place. As always, feedback and questions are welcome!

Benny Cheung

Benny Cheung

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.