The next question to consider is selecting a connector system for the project. For that, we have a lot of materials to start with. Let me list a few here.

- Qwiic Connector System - https://www.sparkfun.com/qwiic

- Feather - https://learn.adafruit.com/adafruit-feather

- Pmod - https://digilent.com/reference/pmod/start?srsltid=AfmBOorRatG-ZxxxYxxMiF7oObGWU7YAchuTd6O5kCFwzHRLJvIiHQ03

- MikroBUS Click Board - https://cdn.mikroe.com/cms/click-boards/click-board-standard-guidelines-april-2019.pdf

- Raspberry Pi header - https://www.raspberrypi.com/documentation/computers/raspberry-pi.html#gpio

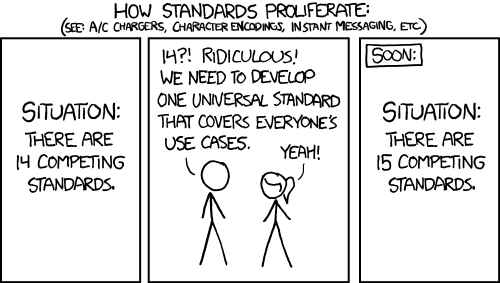

There are tons of options available on the market. Just like creating a new standard, there are always pros and cons to selecting which system.

At the end of the day, the connector isn't just a plug—it's a promise of connectivity. Our main feature here is delivering a unified interface that handles I2C, SPI, UART, and GPIO without breaking a sweat. Why these? They're the Swiss Army knife of maker and industrial comms:

- I2C: For daisy-chaining low-speed sensors and peripherals. It's everywhere in Qwiic/STEMMA worlds, and we'll make it the default for quick expansions—think temp/humidity modules stacking like pancakes.

- SPI: High-speed data for displays, SD cards, or precision ADCs. Pmod-style headers nail this, and it's crucial for our IO modules handling real-time analog signals.

- UART: Serial bliss for debugging, GPS, or modem links. Shields and HATs often expose this cleanly, and we'll ensure it's there for custom MCU handshakes.

- GPIO: The wildcard—digital pins for buttons, relays, or whatever wild idea you throw at it. This is where Arduino/RPi influences shine, giving users raw control without abstractions.

- Power: Most importantly, VCC and 5V for powering the board, which is equally crucial.

My current approach is to mix and match different systems: using Pmod (1.27mm pitch) for GPIO, Qwiic for I2C, and a 6x2 1.27mm pitch IDC connector for all SPI, I2C, and UART. Power will be using JST XH connector for a max of 3A power delivery. I guess this mostly covers all the use cases as illustrated in Pmod (but I don't understand why so many boards use SPI—maybe because of speed?). Coming up next, probably some real designs for your review. Stay tuned.

Benny Cheung

Benny Cheung

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

There is a small 2mm pitch box header version of Mikroe you can use with https://www.mikroe.com/shuttle-click perhaps you could include that on your PCB?

UEXT is a similar (and older) concept https://www.olimex.com/Products/Modules/ including one of those would enable using these off the shelf open hardware modules https://www.olimex.com/Products/Modules/Interface/

Are the PCB JSON you shared EasyEDA? I didn't successfully open them yet

Are you sure? yes | no

Very nice suggestion. I think I will consider the UEXT connector. mikroBUS just seems odd to me to include analog input and PWM as they can be easily implemented by I2C IC.

I will fix the PCB JSON later. They suppose are EasyEDA readable but I have no idea what happened.

Are you sure? yes | no

Do you have a link to the EasyEDA project? I would be interested in having a look

Are you sure? yes | no

I see. What comms are you focusing on? I tried to default to RS486 but with Canbus or SPE as addons via a shield.

My Microcontroller stuff was based around https://www.olimex.com/Products/Duino/STM32/OLIMEXINO-STM32F3/open-source-hardware yes it's an old/ legacy footprint, but industrial rating counts for a lot in this space I think. On-board Canbus is nice too

Are you sure? yes | no

I think it will be a more universal platform to cater for different communication method.

Are you sure? yes | no

I did bit of digging into somewhat adjacent things and ended up with this https://github.com/samuk/IoT-Greenhouse-Temperature-and-Irrigation-Controller-Node-Red

Essentially a bunch of Olimex stuff on a custom carrier https://easyeda.com/editor#id=0fb0bc8a8a284d4f8c591254ed1418f7|7221dde35d414902bdfeba2d03370245|b370bd9c568b42909310514aeeca46e3|a863dc0108f74cb184ebf043b9bd98b7

So that it could work with hat rack https://plasmadan.com/product/hat-rack-mini-raspberry-pi-hat-mount/

And therefore the nice (but proprietary) https://sequentmicrosystems.com/

Are you sure? yes | no

Actually, I am developing a similar project and have come up with this idea. The concept is very nice, but you can achieve it on any kind of platform. However, once you complete the development and want to make it last long, it will present a different challenge.

Are you sure? yes | no

Indeed, that's why I've gone for the industrially rated Olimex components as the core, with the hot-swappable EMMC chip. It's not fully 'industrial' but somewhat more robust than a Pi for example.

Are you sure? yes | no

I'm curious why you decided to not use the Mikroe click?

Are you sure? yes | no

I think the concept of Mikroe is more oriented towards development tools, and the Click boards do not have standard dimensions. This creates significant difficulties in building an enclosure system around the platform. The stacking methodology is also not ideal for integration with casing. The two rows of headers also occupy quite a bit of space and make the board relatively large. I am thinking of a DIN rail casing scenario, and I definitely will update the logic here in a later log post.

There is also some attempt on what I am trying to acomplish as below but seems it is a bit unrefine:

https://www.hwhardsoft.de/english/projects/arduibox-feather/

Are you sure? yes | no