Introduction and Motivation

I'm Olivia Heui Young Park, an Assistant Professor in the Mechanical, Aerospace, and Acoustical Engineering department at the University of Hartford. I have always believed that things only have meaning when they are shared, and one of my goals during my Ph.D. (at Penn State!) was to host a series of hands-on, build-your-own workshops for anyone interested. I'm a huge advocate for hands-on learning, and believe that it's important that every single person gets to have something physical to take home, along with translatable skills like programming, CAD, prototyping, designing, soldering, etc. I was graciously funded by Penn State's Center for Acoustics and Vibration during my last year of Ph.D., and was able to finally host a series of workshops. This project is one of those said successful workshops, where both undergraduate and graduate students with varying backgrounds and majors participated. The first workshop focused on CAD and rapid prototyping using OnShape (cloud-based freeware you can use to collaborate with others). The second workshop was the build day, where students built their own speakers. I took my speaker and tested it in the anechoic and reverberant chambers of our new labs in the Engineering Colaborrative Research and Education (ECoRE) Building, and presented at the 188th Meeting of ASA (New Orleans), 4pED8.

currently playing: NIKI - Every Summertime

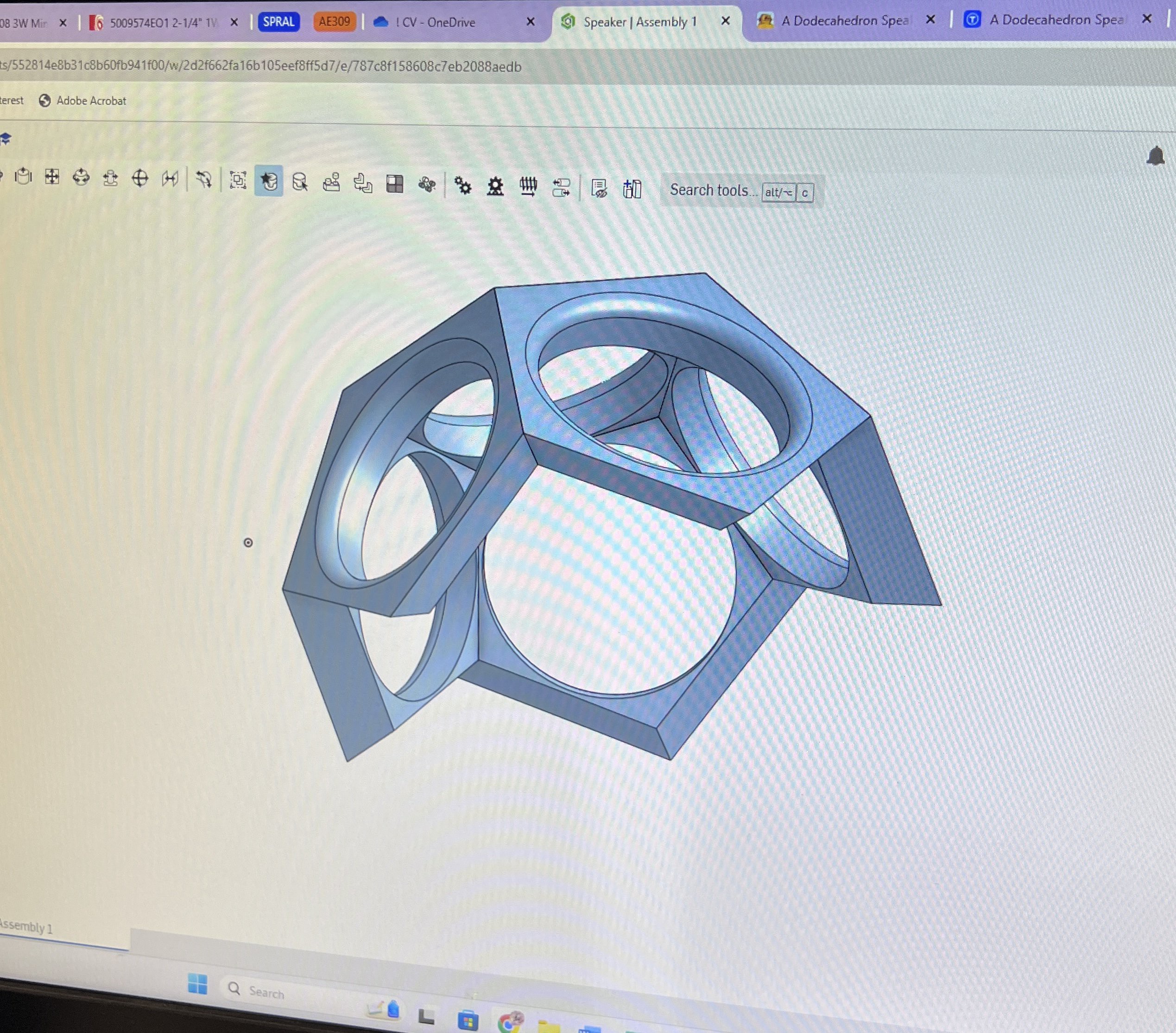

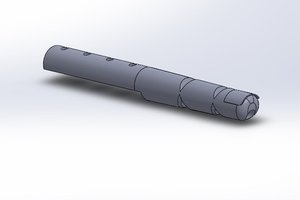

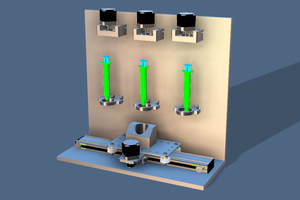

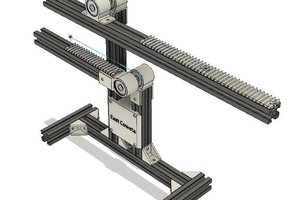

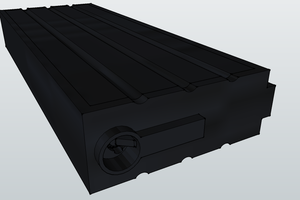

CAD and Prototyping

I wanted to make sure that all the students, including those with ZERO experience with CAD, learned the basic tools so that they can continue using CAD to prototype things for other projects as well. Thus, instead of giving vague design conditions, I had built a CAD model that I know works, and walked through it step by step. The PowerPoint presentation can be found in Files, along with the .STL model of both the single and 6-sided faces of the speaker. i also let the students choose to make design choices if they're comfortable with CAD. i did have one of the students who participated tell me that he was able to use OnShape for his research thanks to my workshop, so goal achieved! For those who want to add a bit more of a challenge, you can vaguely give design considerations, and have a competition to see who can design the most efficient, smooth, pretty etc. functioning speaker casing.

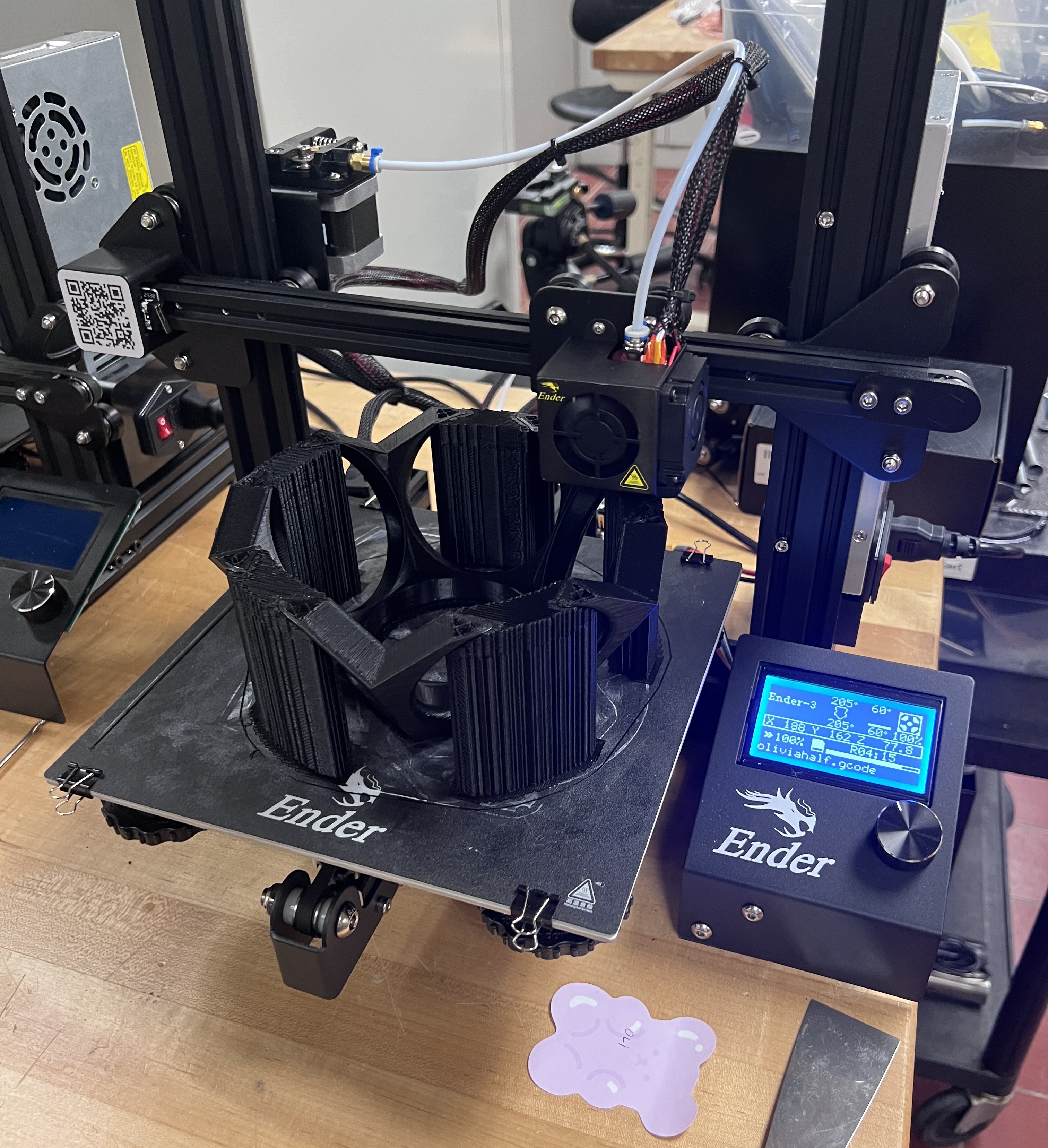

Then, I was in 3D-printing jail. I decided to print all of the faces for all participants, as we had limited resources. I have over 5 years of working with 3D Printers while serving as the MakerSpace TA and the STEM Outreach TA at the Cooper Union, where I got my bachelor's and master's in mechanical engineering, so i felt comfortable printing all the parts. Again, this part can be modified so that student learn the basics and good practices of 3D printing!

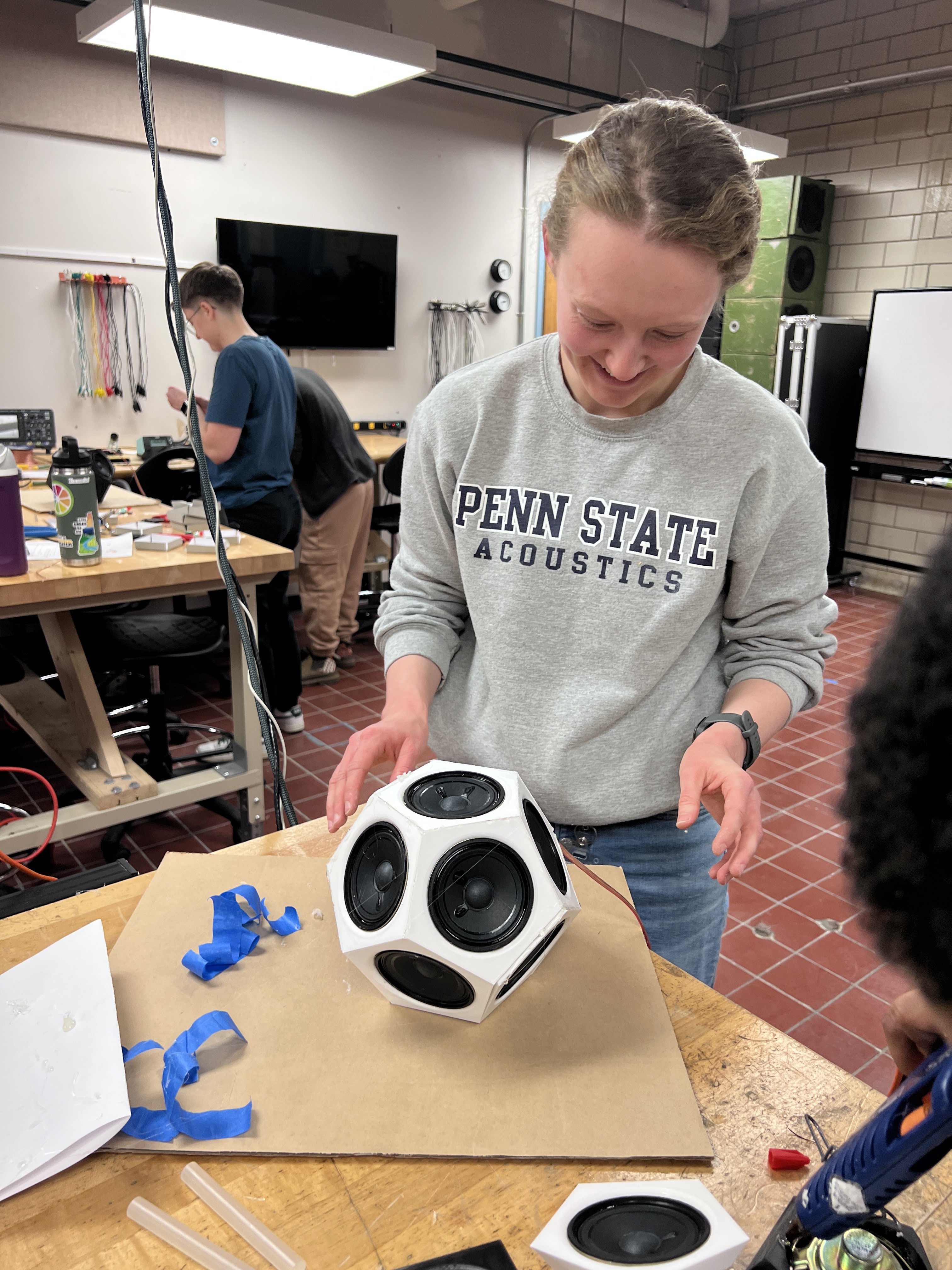

BUILD Day!

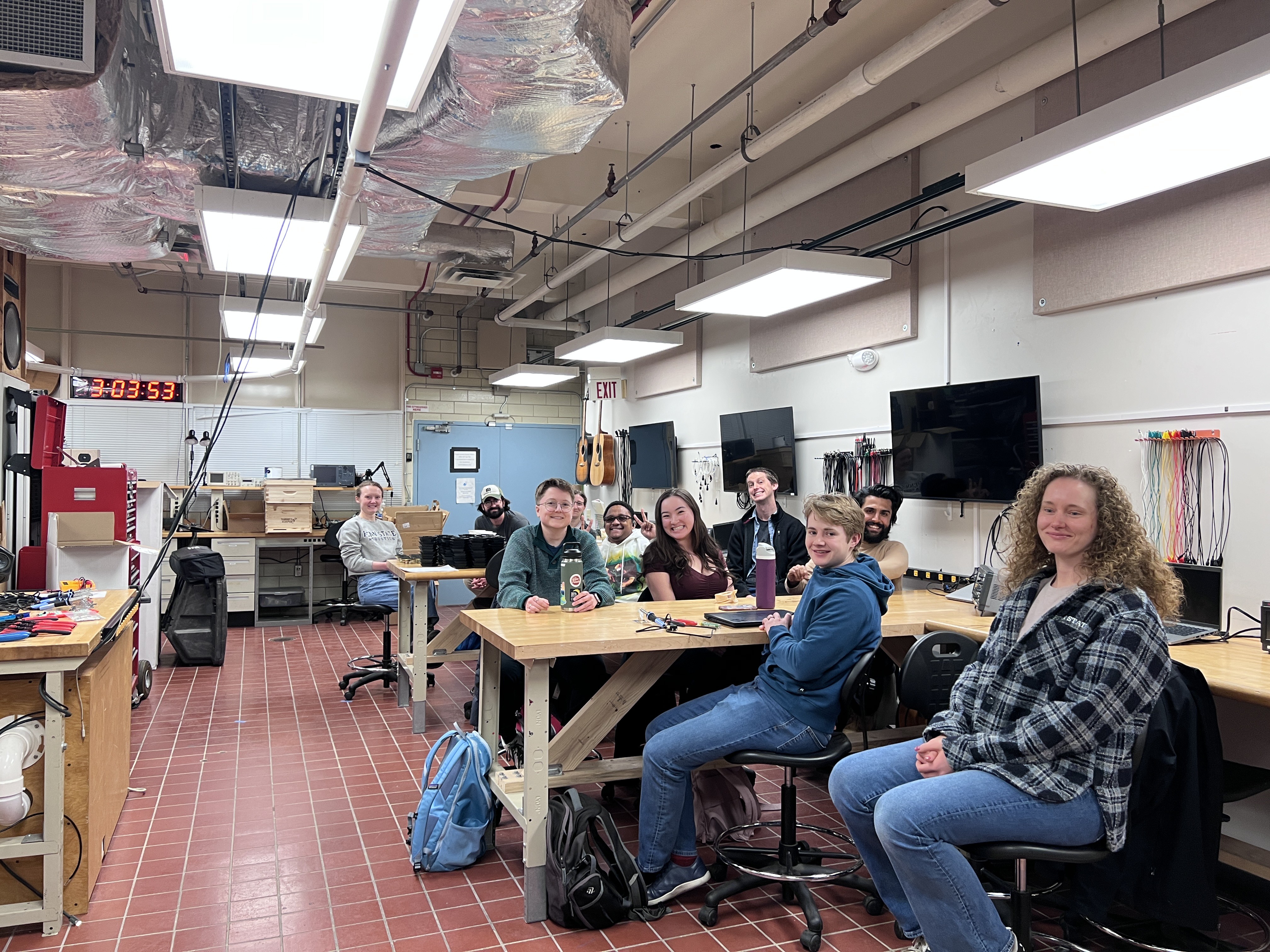

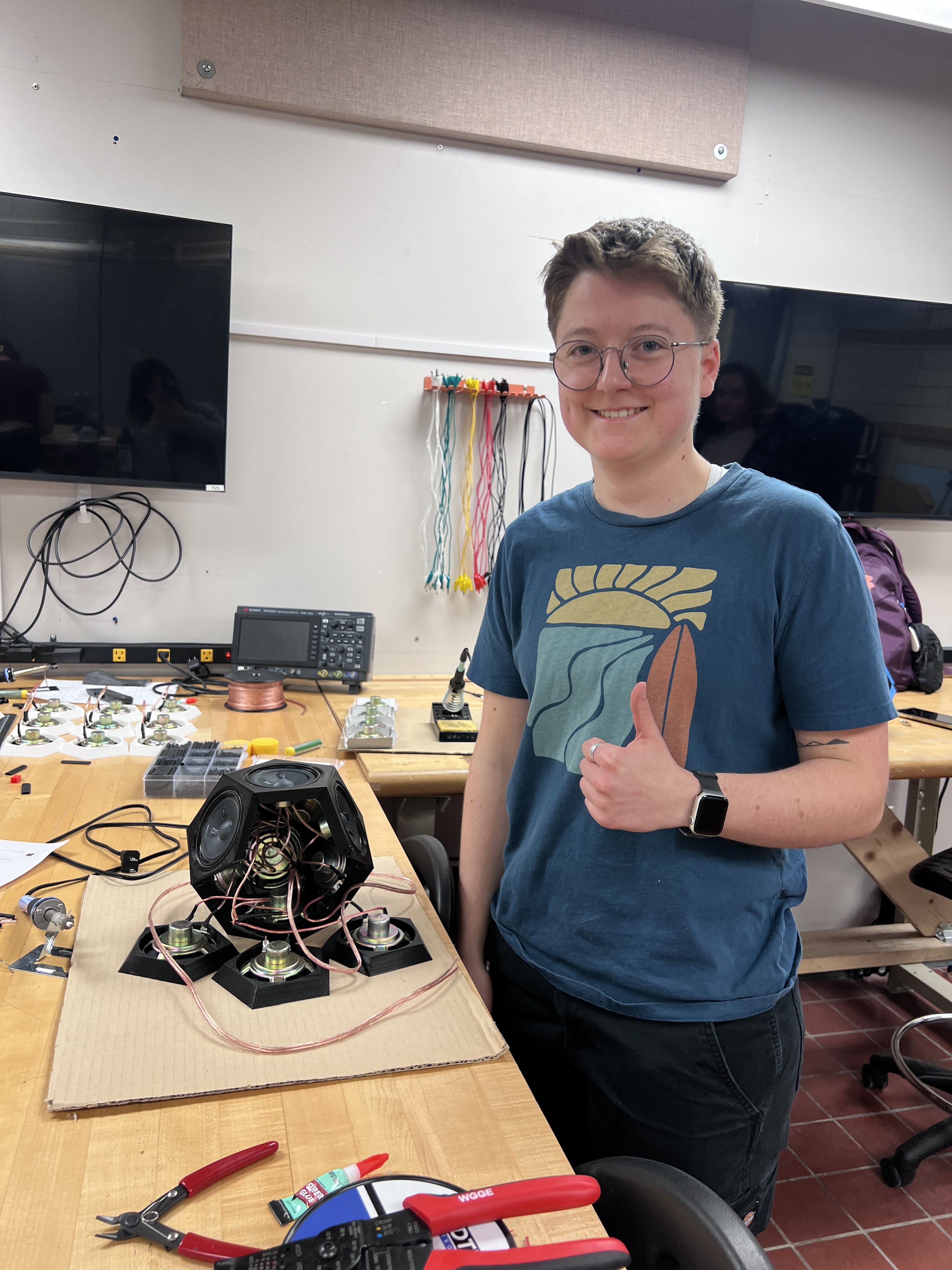

We had 15 students participate, again with varying background knowledge and skills. Everyone was able to either take a fully functioning dodec speakers home, or took almost-finished dodec speakers home!

happy happy faces of dodec speaker owners

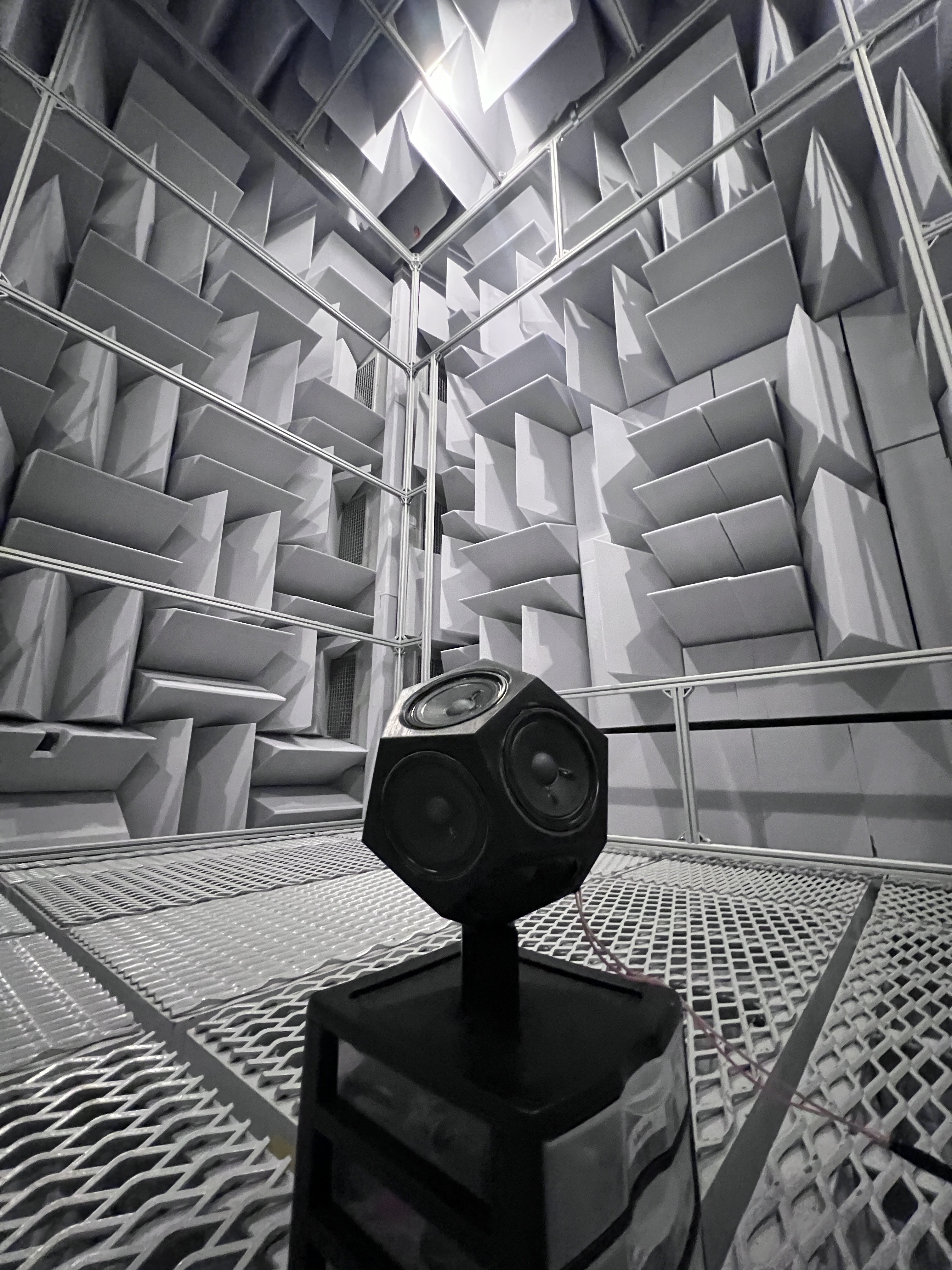

Evaluating Speakers

I took my dodec and played logarithmic sine sweeps in the anechoic chamber and the reverberation chamber. You can find videos of these below. What's cool about this project is that again you don't have to stop at just the build, but expand the workshop so that students learn how to take measurements, to process their data with signal processing, and to analyze the speaker's performance and compare how they behave in the anechoic chamber and the reverberation chamber!

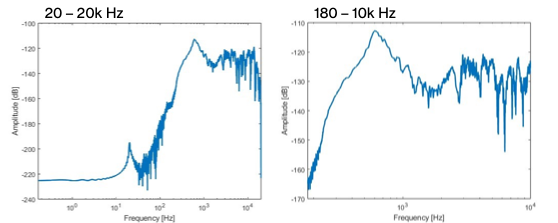

Frequency response functions of the dodec speaker measured in the anechoic chamber with laptop microphones. Not bad !!! pretty flat and nice for the target frequencies.

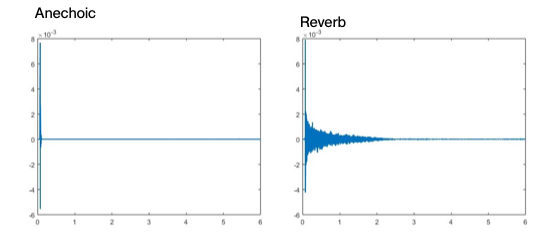

Comparison between the anechoic and reverberant chamber, through impulse response measurements! Again, with laptop microphones - not bad!

SO.... HOW DO YOU BUILD IT?

All necessary files are in the "files"...

Read more » Olivia Heui Young Park

Olivia Heui Young Park

Alan Chambers

Alan Chambers

Jason Cho

Jason Cho

TAIBHSE DESIGNS

TAIBHSE DESIGNS

Have you considered putting some small spheres on each vertex? Then it would resemble those mysterious Roman dodecahedra... :)

https://en.wikipedia.org/wiki/Roman_dodecahedron