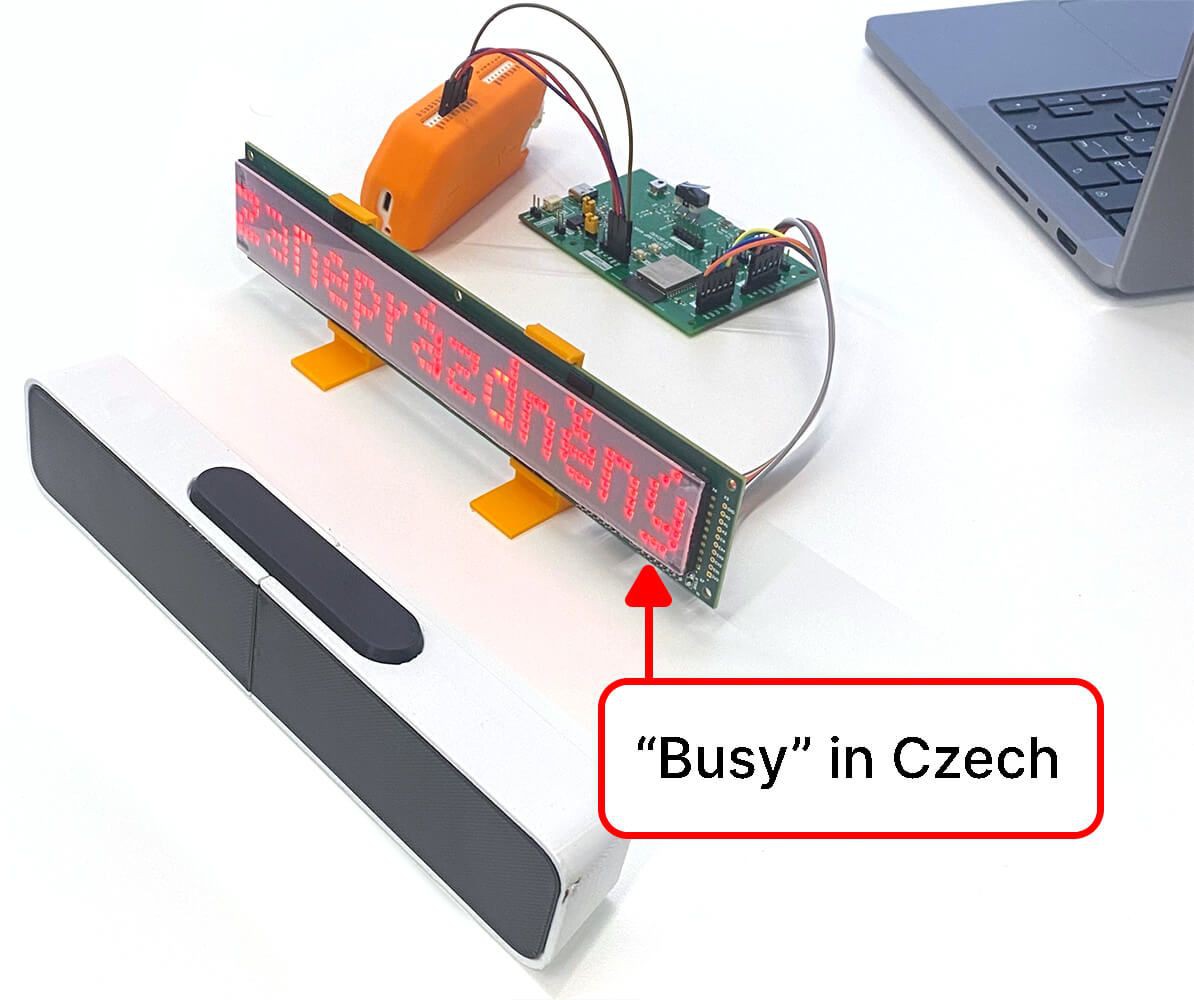

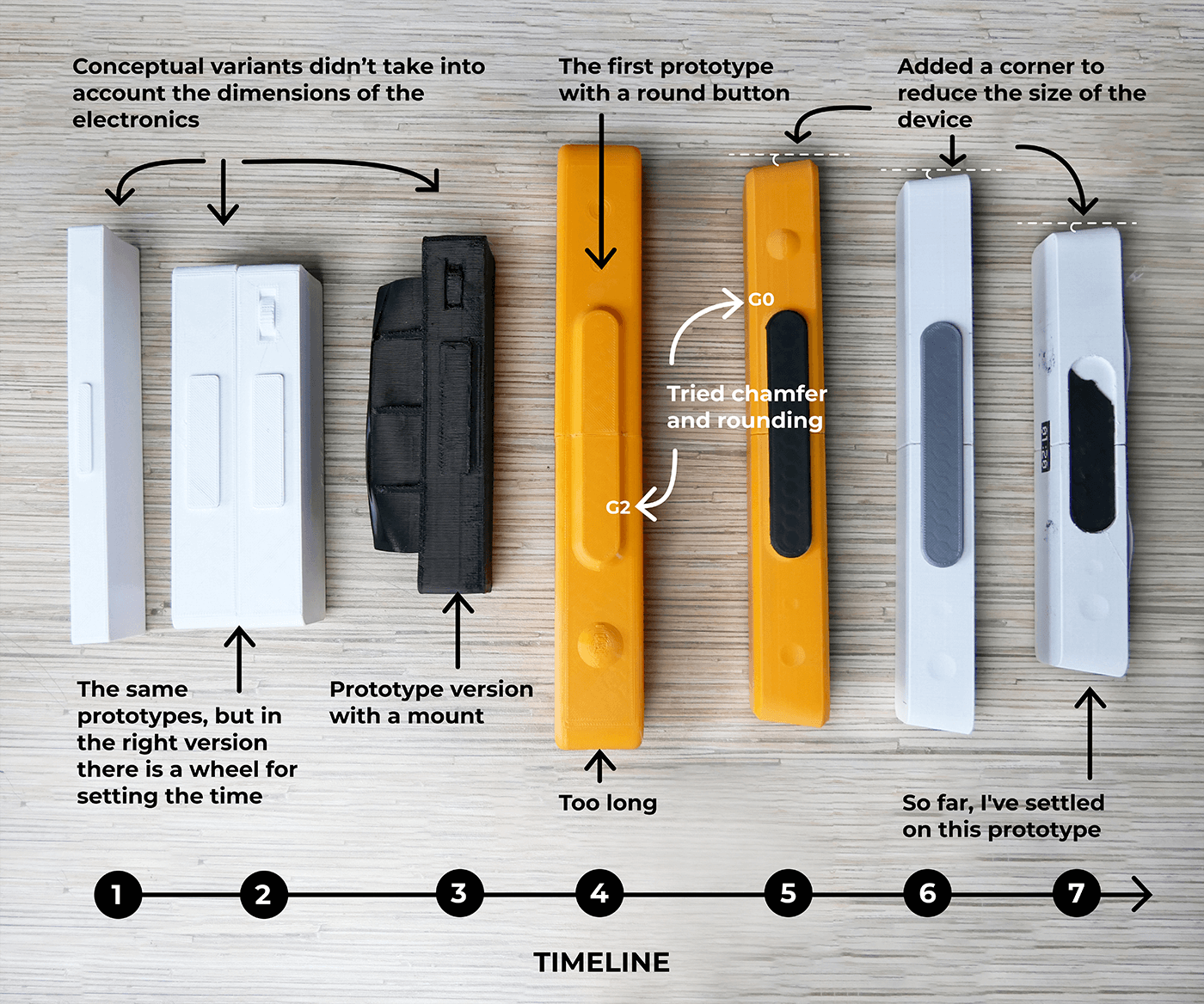

This project was born out of our own frustration with open spaces — there are just so many distractions that it's nearly impossible to focus. BUSY Bar is our attempt at creating a big “SHUT UP” button. When pressed, it uses physical displays and digital integration to silence the space around you, so you can actually get some work done.

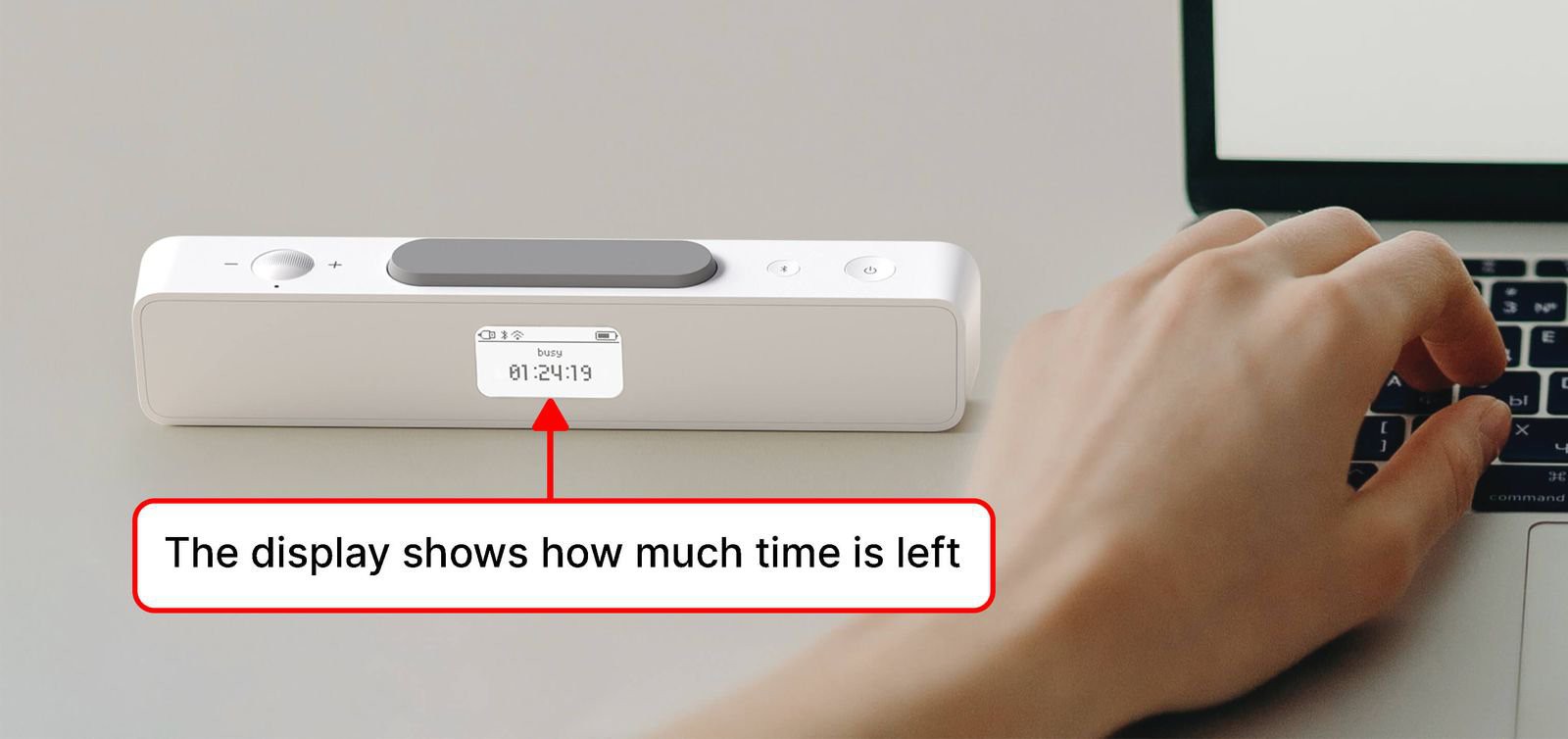

It’s also an advanced Pomodoro timer that helps you stay focused while working on large tasks by alternating between work and rest cycles. During work sessions, you can display a custom status on the screen to let others know that you’re busy and when you'll be free.

We have many more features planned and will come up with new ones as the project develops, so we invite you to keep an eye on its progress!

Ruslan Nadyrshin

Ruslan Nadyrshin

Evangelos Petrongonas

Evangelos Petrongonas

dariocose

dariocose

jeremy.geppert

jeremy.geppert

vishal soni

vishal soni