After much introspection, it looks like I am going to make some changes:

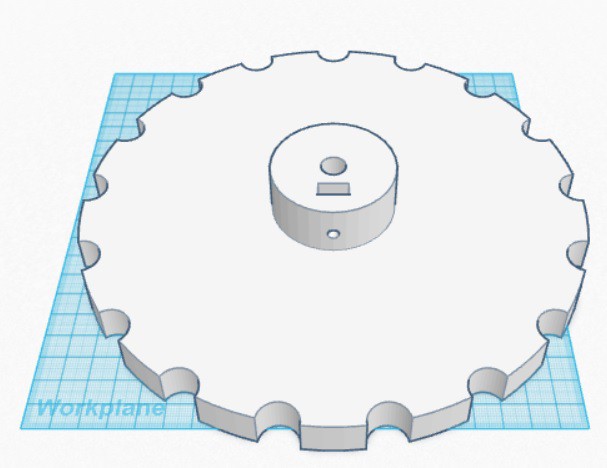

- 3D Printed drive and idler sprockets at 17 teeth instead of 11

- 3D Printed road wheels (yes, printed), but also at 17 teeth, that will raise the chassis of the tank higher off the ground.

- Move forward with making the tank based on a metal frame instead of a wooden one. 2 of the 2x4s will be recycled as longitudinal support members

- Fiberglass surfaces so that the batteries can be mounted inside the frame cavity

Plastic wheels and sprockets will save the track a lot more, and based on initial estimates will suffice for prototyping. They may not handle heavy duty operations, but it's pretty easy to cast aluminum replacements afterwards. I do intend to print in PLA at 100% in-fill.

Here's an image of the sprocket/idler:

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.