The last few weeks have been completely hectic and I have been unable to find time to document progress. I’m currently on a flight from London to Los Angeles to take up a residency at Supplygrame’s DesignLab to work on the glider, so I thought it would be a good time to do a few updates on the glider’s progress. I’ll split the update into two shorter sections, one for the buoyancy engine and another for the backend.

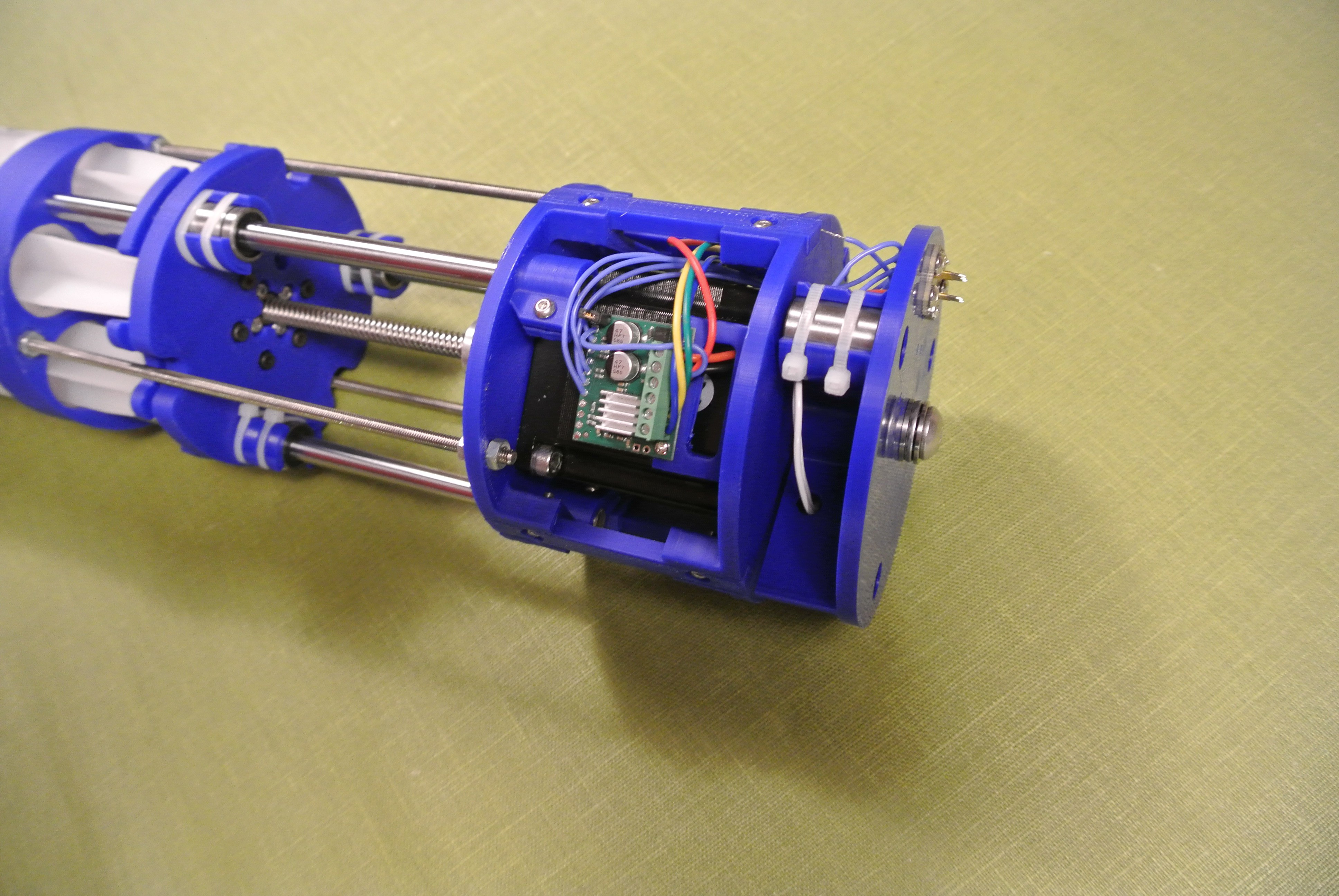

Throughout most of the upgrade from version 3 to 3.1 I have been thickening components to improve structural strength, notably in the buoyancy engine. Below are two images of the engine, before and after the upgrade.

Also note that the stepper motor has been upgraded from a

NEMA 17 to a NEMA 23 motor, which runs at an equal power but has far

greater torque. I have also moved the buoyancy engine stepper motor driver from the control board to mounted at the front of the glider, so that communication wires

can be of a lower gauge and greater power can be delivered to the

engine’s stepper motor. I have also upgraded the stepper motor from

a A4988 to an AMIS-30543, as stated in my previous update. This

allows for SPI communication to control the stepper motor more

accurately and alter coil current on the fly.

All of the glider’s components in contact with water are rated to a depth of at least 100m, apart from the buoyancy engine. Therefore a depth rating of the glider can be determined by pressure testing the buoyancy engine (unless it can perform to a depth greater than 100m, which is almost guaranteed to be false). Hence I meant to test the buoyancy engine, however I was time constrained and air is a harder medium to deal with than I initially thought. Regardless, I’ll outline briefly the attempted testing method for anyone is interested.

The

idea was to connect the engine to a water barrel using the same

tubing and connectors that are within the glider, to try and

accurately represent the system used. The barrel then had a pump

attached (it was a car tyre pump until a lack of suitable power

source became an issue) to pressurise the water within the container

until the engine failed. The engine would constantly pump as I

believed the syringe seals were more likely to fail when moving.

Unfortunately the seal at the top of the container wasn’t

sufficient and even after multiple layers of airtight tape there were

small leaks that would reduce pressure within the container. I was

going to switch to using a silicone sealant to properly air-tighten

the container but I ran out of time.

alexw

alexw

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.