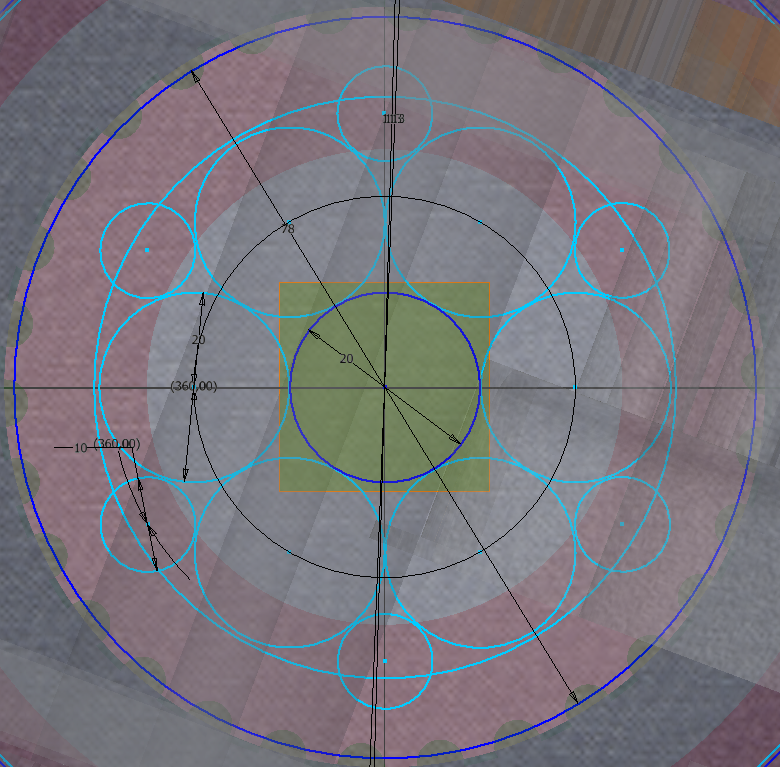

The structure will be mostly in aluminium, with square profiles, i studied the capabilities of this kind of structure and it can work fine. i solve the problem with the horizontal movement with a set of cilindrical aluminium profiles, exactly with 7 of 20 mm of diameter and 6 of 10 mm, i choosed this solution because it is cheaper than a large cilindrical profile and has much more strenght, this set will be joined with 3d printed part and holded by 3 bearings, 2 lazy susan with an 80mm diameter and 1 to support the vertical force, in those 3 images you can see the system.

The first one, is a 2d sketch, the possition of the profiles. The blue circle marks the limit of the 3d cover.

The

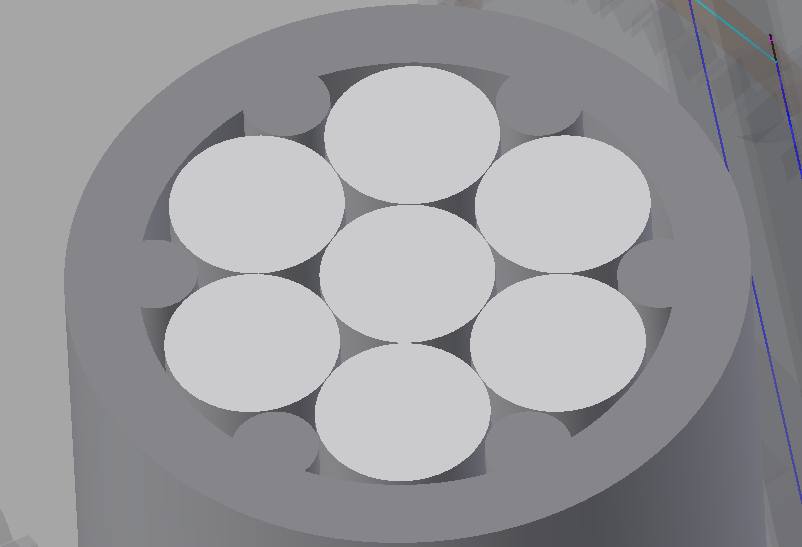

second one, you can see the cover, with 7 circular profiles of 20 mm

and 6 of 10 mm, all the profiles will be empty so i will pass alt he

cables to the rest of the arm by the central one.

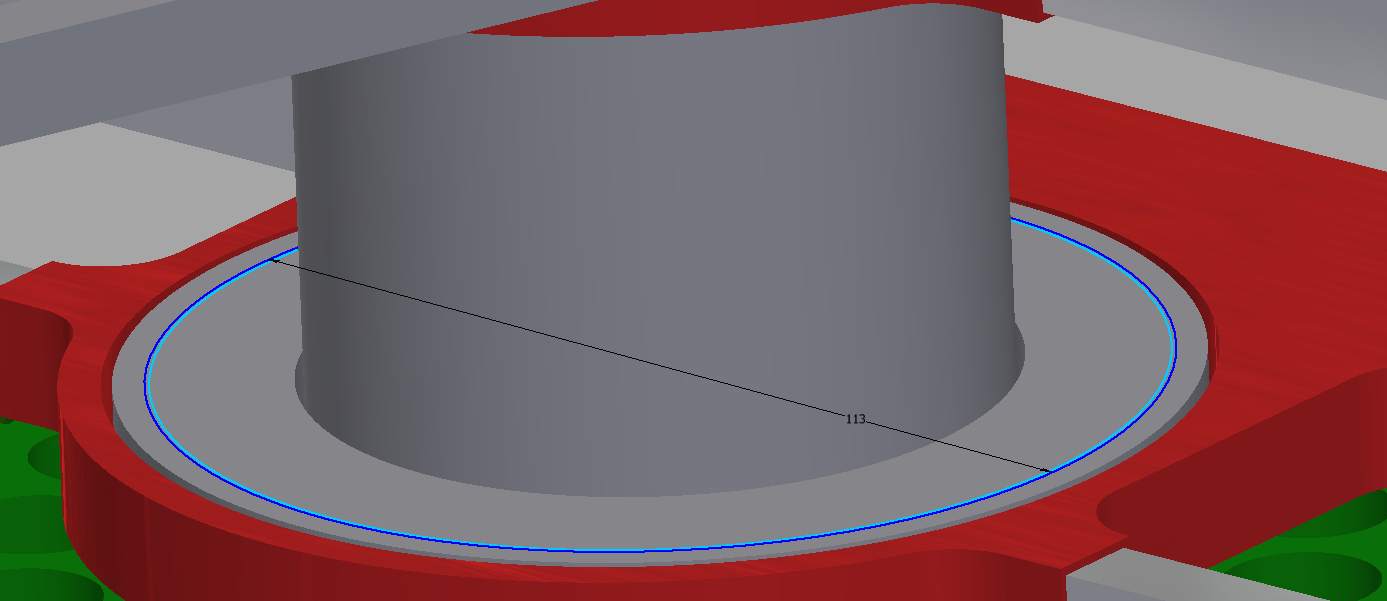

In

this image you can see the central column with a bearing, i choose a

lazy susan with 80 mm of diameter, and it will be holded to the

structure by a 3d piece(the red one) and some square profiles of 16 mm.

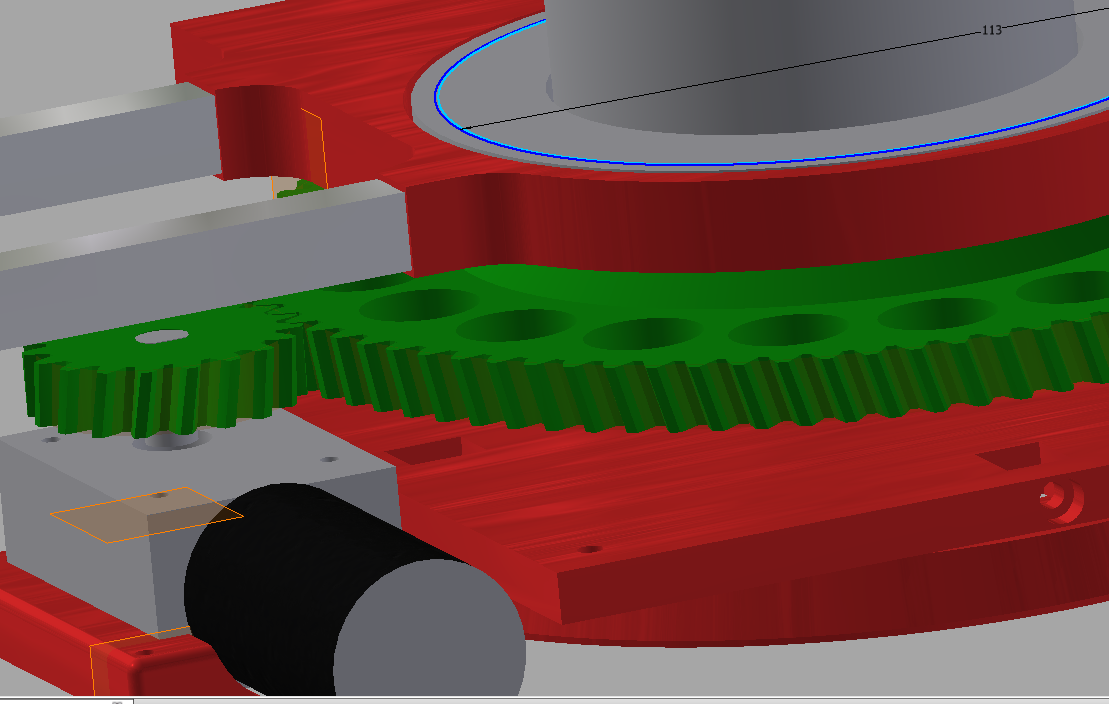

This

is the motor of the horizontal movement, with 3d printed gears, under

the central column there is an encoder so i can know the position.

Antonio Regueira

Antonio Regueira

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.