After assembling the first, then the second arm, I am really getting tired of tapping all those threads manually in the plastic. I am thinking of just using heat-inset tapped inserts but it would be another thing to buy for everybody. Also bolting the motors and joints take too much time (especially with nylock nuts). Any suggestions for making things easier?

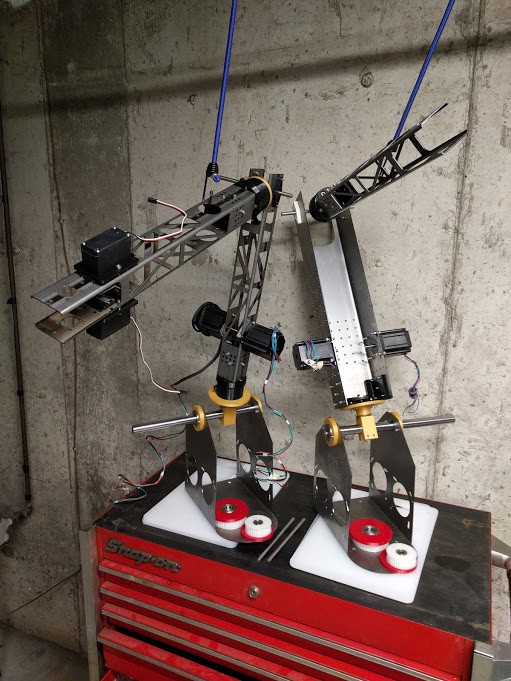

Here are pictures of the two together.

Already so many parts need some redesigns, I'll be updating the STLs on Github hopefully before the weekend.

What feature do you want to see in the robots? Any suggestions for the next post?

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

The stuff missing for an initial proof of concept is getting the base NEMA34 standoffs machined and the pulleys made...

Are you sure? yes | no

Holy! That escalated quickly! Awesome work!

Are you sure? yes | no