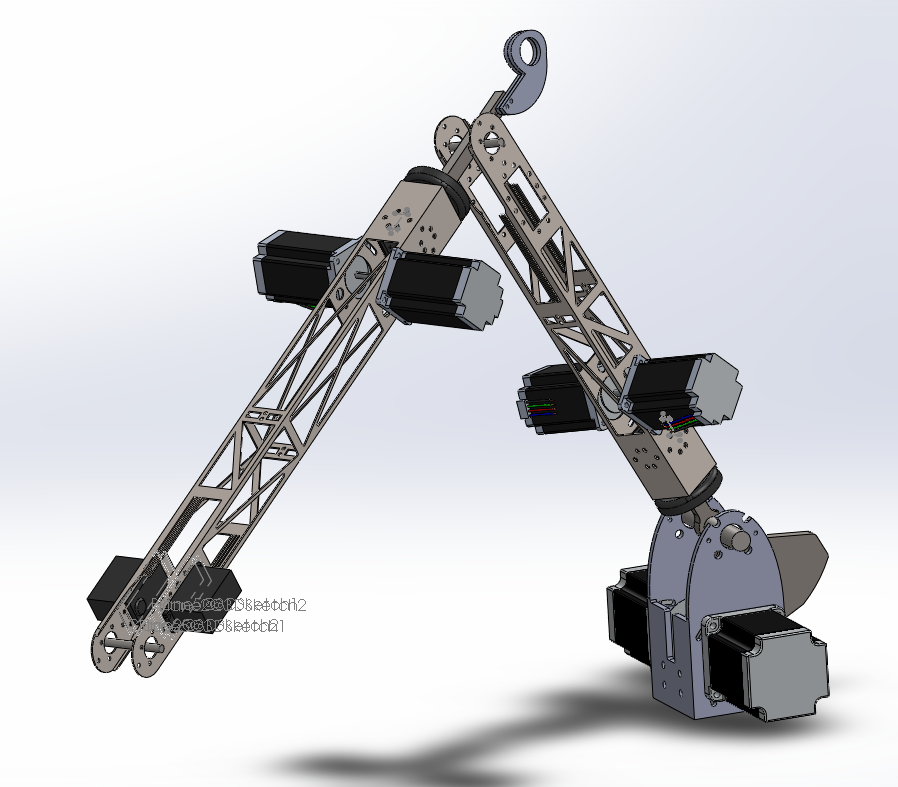

After having built the first two iterations, I realized I needed a better base design. I wasn't happy with the accuracy or stiffness of the 16ga steel folded at 90degrees so I have decided to move the motors eternal to the arm structure, which ends up making it quite a bit more compact. It is also a bit similar to the design now in use by Boston Dynamics "mini cheetah" / electric mini-dog arm.

Here the motors are still NEMA34s geared ~4:1 or 5:1 to the 20mm axle.

Here the motors are still NEMA34s geared ~4:1 or 5:1 to the 20mm axle.

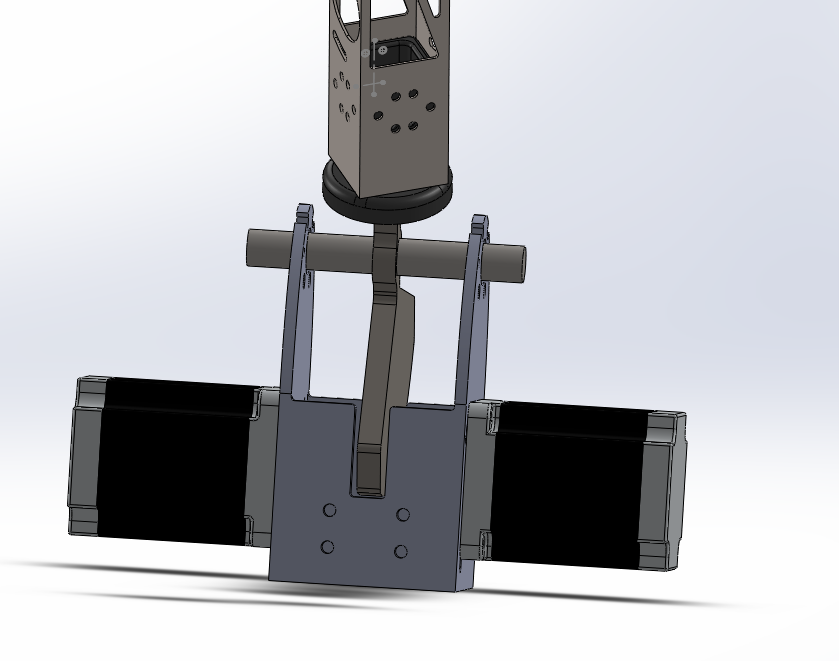

In order to counteract the base torque, I have added a counter-weight (with associated cutouts) which also acts as the thrust washer mount/pivot. The counter-weight is massive - 1/2" steel plate laser-cut, weighing around 3 lbs!

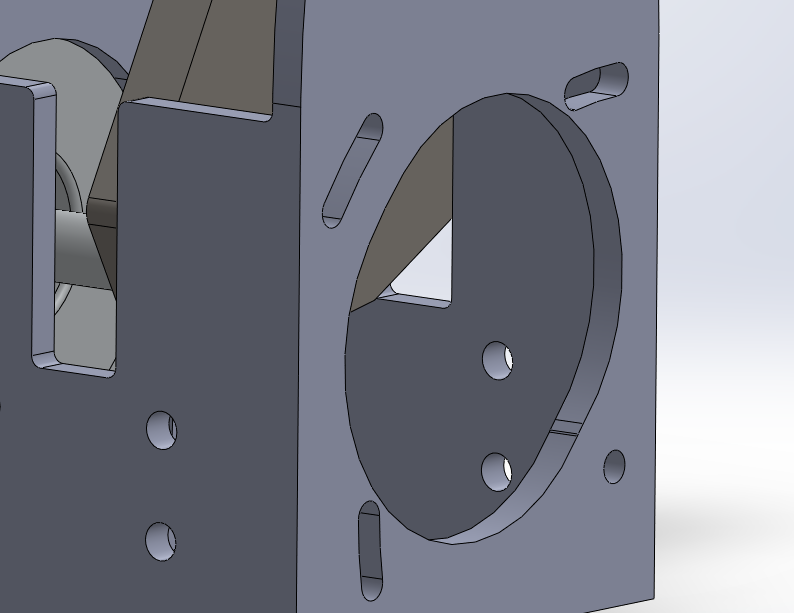

I have kept the original adjustable base tensioner:

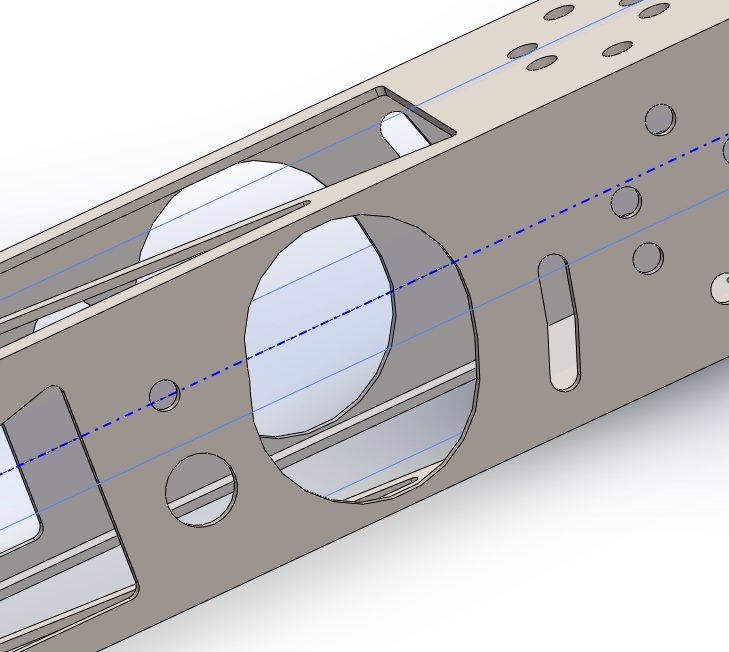

and now also added them in the arms:

Here you also see one of the modifications I did for assembly - the motors are installed on the diagonal (small hole + slot). The larger hole is for being able to assemble the opposite side motor.

Thoughts on the redesign?

I have ordered the parts and hope to start assembling this weekend (iteration 3). It's a long process and I hope to get the motors moving soon.

In the meantime, I will try to get the existing arm moving a bit. I have bought three Makerbase MKS V1.3 32-bit smoothie clone boards as testbeds (so I don't fry my legit Smoothieboard 5XC), I hope to connect them up and start testing soon.

Thanks for listening.

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.