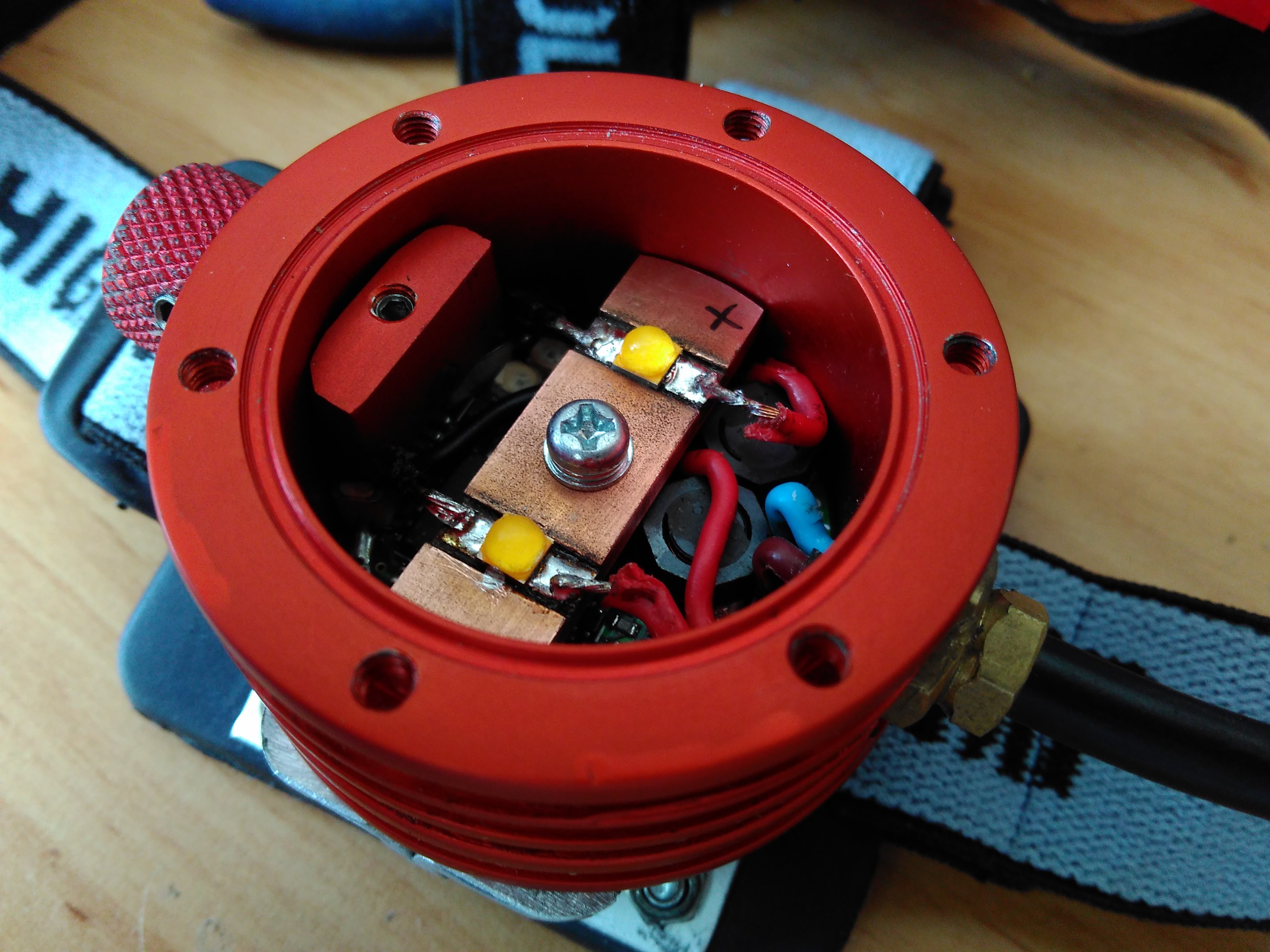

I've been experimenting with soldering LEDs directly to the cooper heatsink. A piece of cooper was milled to desired shape, led thermal pad is soldered directly to the heatsink and other two pins are soldered to small pieces of FR4 i inserted below.

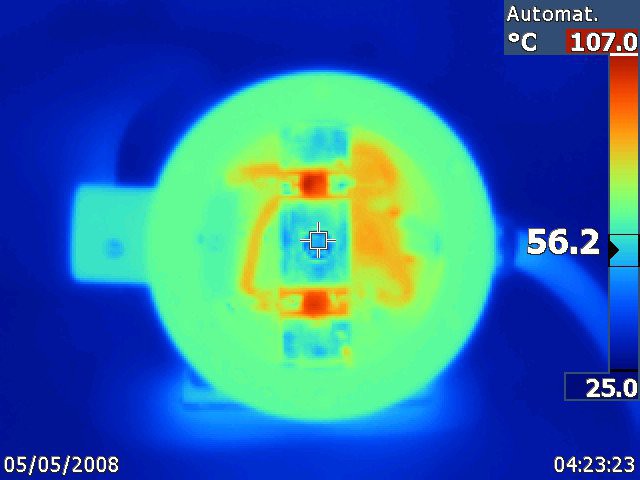

I expected much better heat dissipation and lower LED temperatures, unfortunately the temperature settles on 107 °C. That makes me wonder, what's wrong. LED not correctly soldered to heatsink? I don't think so, it lies directly on the cooper with thin layer of solder. LED damaged during soldering? Bad thermal contact between the cooper and the aluminium body? Small surface area in contact with heatsink? XP-L2 is quite small, on aluminium heatsink, there was a thin insulation between the led and heatsink, but the whole LED was placed directly on the heatsink, now only the thermal pad is in contact with the heatsink... Or is there any dark magic involved? :)

Jakub Kaderka

Jakub Kaderka

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.