My last run went well enough, but it left me with a few questions, too.

For one thing, was the base plate not being charged effecting how the fibers were being laid down?

Another one is what's the difference in the fibers between the angled plates and the rotary cage?

To answer the first one I laid down a

piece of aluminum foil between the angle pieces, and pinched the the

foil under them to hold it in place. It was a lot simpler doing it

that way than making another plate. The answer is: no difference at

all. So that solves that.

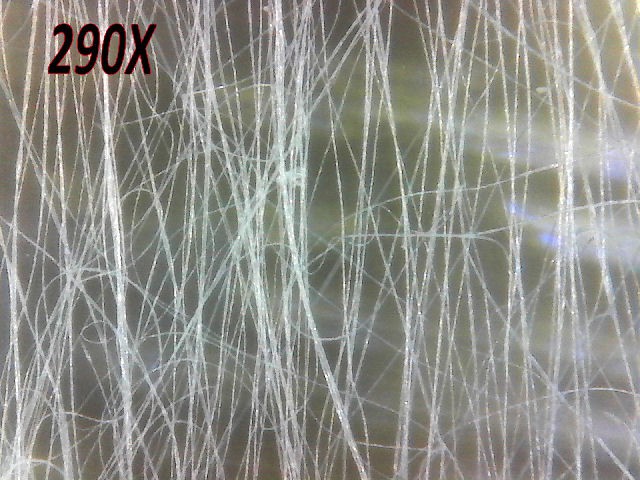

To answer the second question it was as easy as putting the rotary back in and running another batch. I kept the same mixture and feed rate from the above run so all that would be equal. The results rather surprised me. The rotary gave me noticeably smaller diameter fibers, but the angle plates ones, while larger, were better aligned parallel to each other. The rotary ones are also easier to collect.

The first picture below is from the rotary and the second from the angle plates.

The machine is doing well and producing the same results with the same settings day after day. Pretty much if I'm careful to get the mixtures the same I'll get the same results every time. That's good to see.

So now it's back to sticking nanotubes

in the mix and see what I can come up with. The main two goals of

this is to strengthen the fibers considerably, and make more

conductive fibers. All of this is basic stuff, I'm sure. But it's

just something I need to figure out now before we go in even more

directions later.

Douglas Miller

Douglas Miller

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.