-

TerraPreta MK1 - First advance

05/02/2017 at 17:49 • 0 commentsIn order to verify the desired best operations conditions and as well, to know how previous researches on similar Pyrolysis Reactors in batch, semi-batch and continuous processes has been designed, we have verified different articules about Biochar, allowing us to understand that the best Carbon yield would be achieved in a temperature range between 400 and 500 degrees celsius, a pressure higher than the atmospheric, feedstock with a maximum humidity level of 10-20%, crushed with a particle diameter about 2 millimeters or higher and better if exist alkalinity.

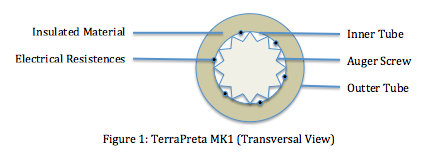

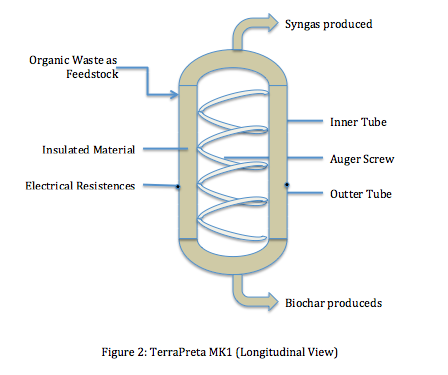

Since one of our principles for this first prototype, named TerraPreta MK1, is to use components commonly found in the market, allowing us to have lower building costs, to make this first version, as much economicaly accessible to everybody as possible, and at the same time we haven’t selected an specific organic waste to use as feedstock, at the moment we present you different views with a general idea about how the All-In-One Pyrolysis Reactor should be as shown in the Figures 1 and 2:

![]()

The TerraPreta MK1 has been designed to convert the organic waste previously crushed in the feedstock in a Double Tube Vertical Pyrolysis Reactor with an Endless Screw rotating in the middle of the inner tube allowing an slow transportation of the material from the top to the bottom while it is being heated. Between the inner and outter tube there is an insulated material that keeps the heat produced by the electrical resistances that are located externally in the inner tube. Finally, the outter tube is covered by an additional insulated protector to ensure that the the visible side of the reactor would have a temperature close to the one in the eviorment, making the heating process as efficient as possible.

![]()

We are currently working on the list of components we are going to be using to build the TerraPreta MK1 Prototype to start processing the purchases orders, and once we’ll have received all of them, we will travelling to San Diego to assemble the reactor.

Our objective is to develop the TerraPreta MK1 prototype to transform organic waste through the application of heat into Charcoal (commonly called Biochar) which is a stable, solid, innocuous material rich in carbon, in order to use it to enhance soil fertility and increase the yield in agricultural production, also allowing us to mitigate global warming by sequestering carbon and probably producing biogas that can be used in the same process to reduce the energy requirements, thus contributing to a better environment.

-

Collaboration from San Diego and Québec

04/24/2017 at 05:59 • 0 commentsOur teammates from other cities Jesse and Jean are prepping up to start designing and performing initial tests.

Jesse did some initial tests in an environment with no pressure applied:

![]()

Jean will focus on designing a working interface from a test toilet to the feeder of the system:

We'll be coming together with Jesse for a full weekend to start building our prototype. Stay tuned!![]()

-

Log 3: We started the 2050 class!

04/07/2017 at 06:42 • 0 commentsThanks again to Professor Pabo to allow us into his class. We're now going to develop our work and documentation under his guidance and post them here as we go.

We're also going to apply to the Supplyframe residency program. Hopefully you'll find us at the lab in the upcoming weeks!

The BOM is coming up nicely, we're being extra careful to select the right materials thus minimizing our initial costs.

-

Log 2: One team member leaving...

04/06/2017 at 02:00 • 0 commentsJean has proved to have an awesome PR personality! We have come in touch with the Professor Carl Pabo of Caltech giving the team a good opportunity to find talented people in the Academia that could help us move the project along. Ricardo will be assisting to the lectures from now on, they're really good (and open to those interested)

We're hunting down the parts for Mk1 and aiming to start building it before month's end. Unfortunately, Jean is going back to Montreal, but he will continue helping the project while he's there.

We hope to have you back in town soon, farewell good friend!

-

Log 1

04/05/2017 at 05:28 • 0 commentsHi all, finally the team is coming together! Ricardo has just arrived and we're brainstorming ideas on how to complete our design and build an initial prototype that could make the idea more enticing, and easier to explain to people. We're going down the route of finding off-the-shelf parts and limiting the welding component to the minimum possible, we're also discussing what type of solid waste to use first. We'll keep on publishing details about the concepts of our project as we go through them. We'll also resort to this project log entries as a means of sharing our progress... so stay tuned!!

TerraPreta

Continuous Pyrolysis Biochar Production Reducing waste and returning nutrients to the soil

Leonardo Zuniga

Leonardo Zuniga