But making ten pieces was very time consuming. Testing piece was mess of wires, hot glued into waterproof box. And all that cutting, striping, soldering, heatshrinking and drilling was very exhausting. Maybe not with one device maked, but with ten, it was. Oh my deer!

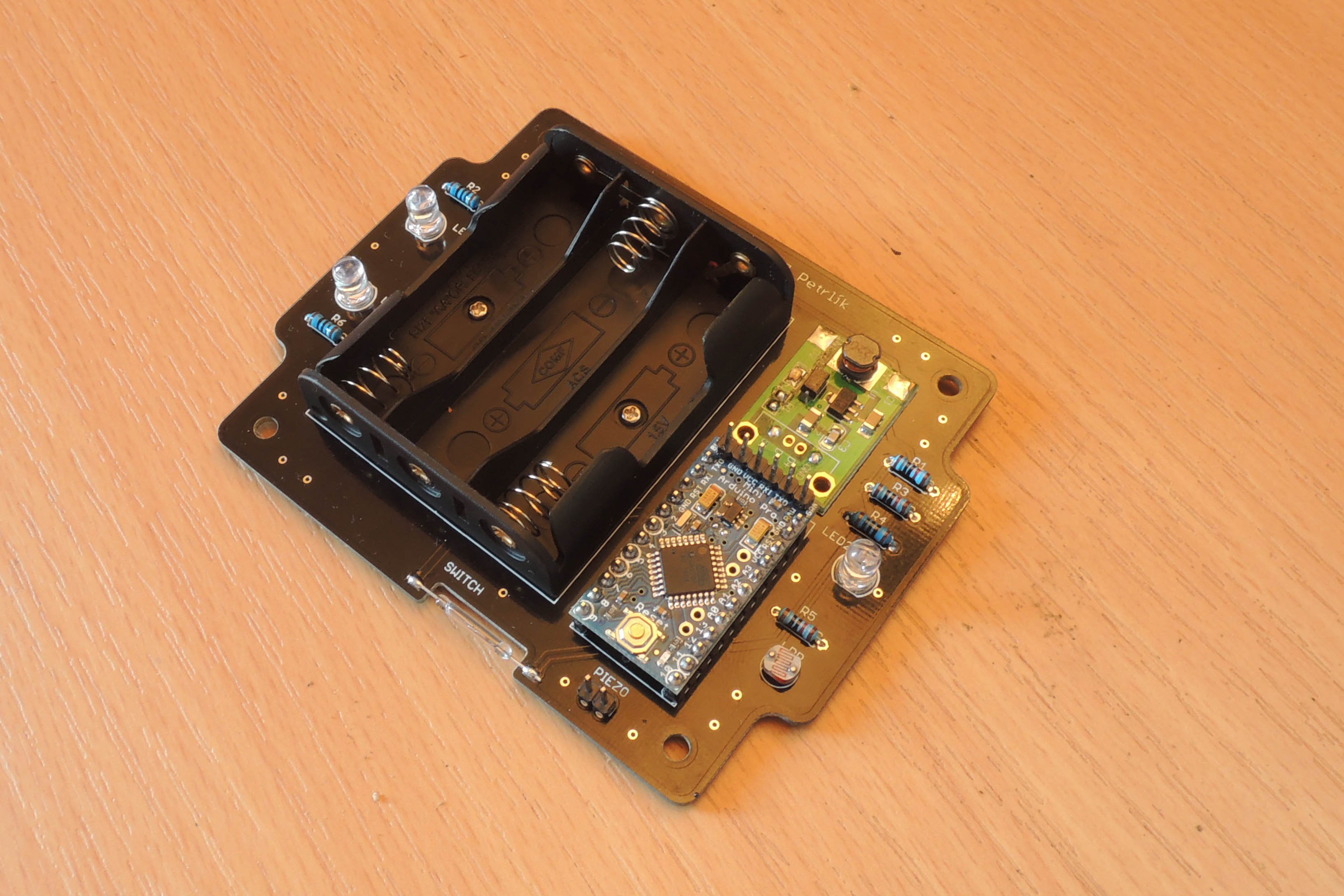

Main goals was design a device with low cost, fast and easy to produce, and which is doable for everyone with basic soldering skills.

So mess of wire was replaced with regular printed circuit board, designed by myself and produced in China. Every other parts was also shopped from chinesse suppliers on favorite websites which everyone knows.

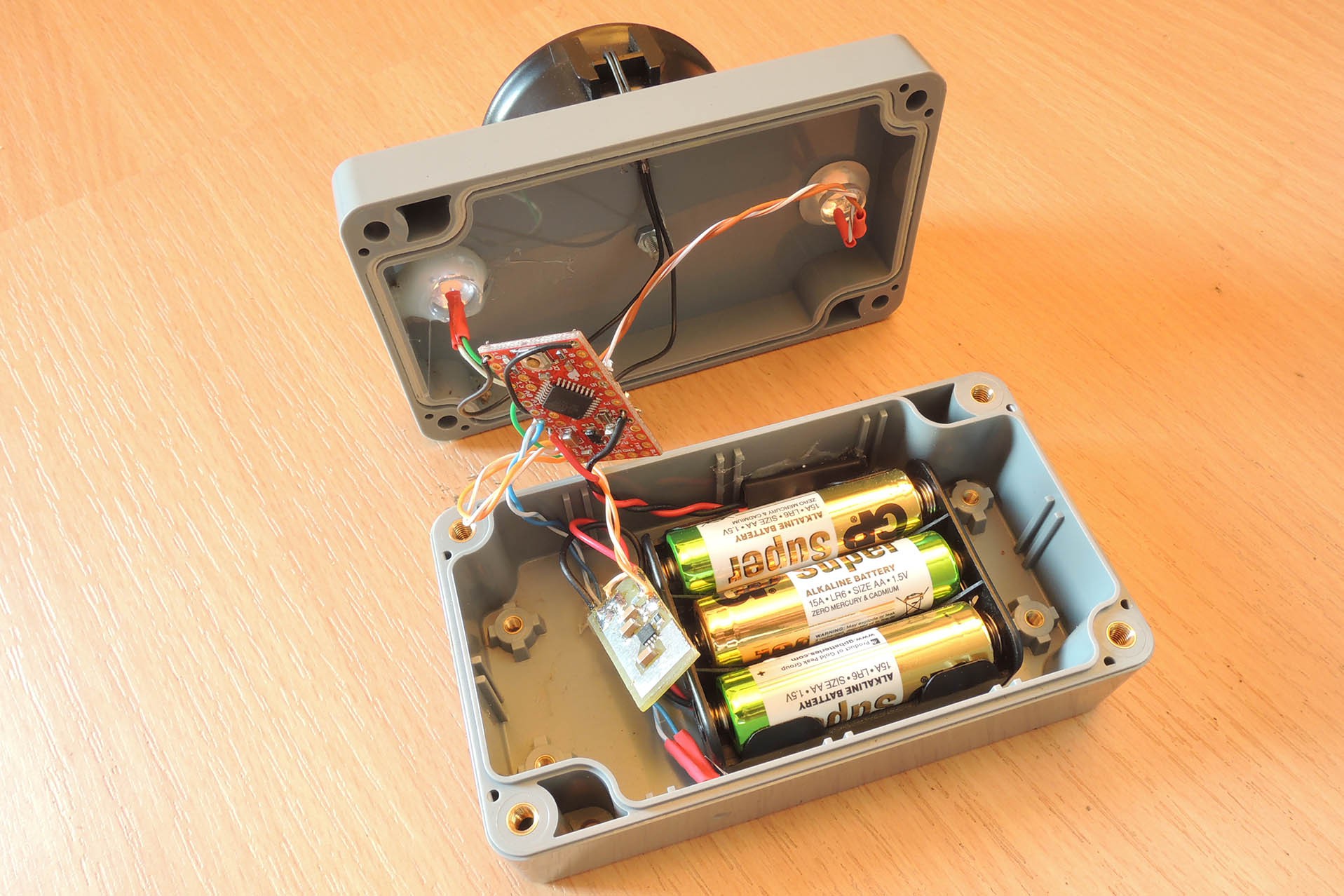

Here is picture of old version, two 10mm LEDs and piezo speaker on front. On top is hole with mounted light depended resistor inside. Used for sensing when it is time to flash with LEDs.

Look inside. Mess of wires with hotglued battery holder which was not ideal for transportation and instalation. On left bottom is homemade PCB with DC-DC converter for powering Arduino mini with 5V. Using higher voltage is better for making louder sounds with piezo speaker.

Near battery box in black heatshrink is magnetic switch soldered on PCB for better durability because it is from glass.

After instalation on place, device is activated by touching of magnet on side of box. It is for eleminating need of opening it with screwdriver only for making activation and deactivation. And anyone not want to drive car traveling to pastures with activated device which in random intervals make very loud random sounds.

Ondřej Petrlík

Ondřej Petrlík

NuclearPhoenix

NuclearPhoenix

Mattis EYNARD

Mattis EYNARD

Ultimate Robotics

Ultimate Robotics