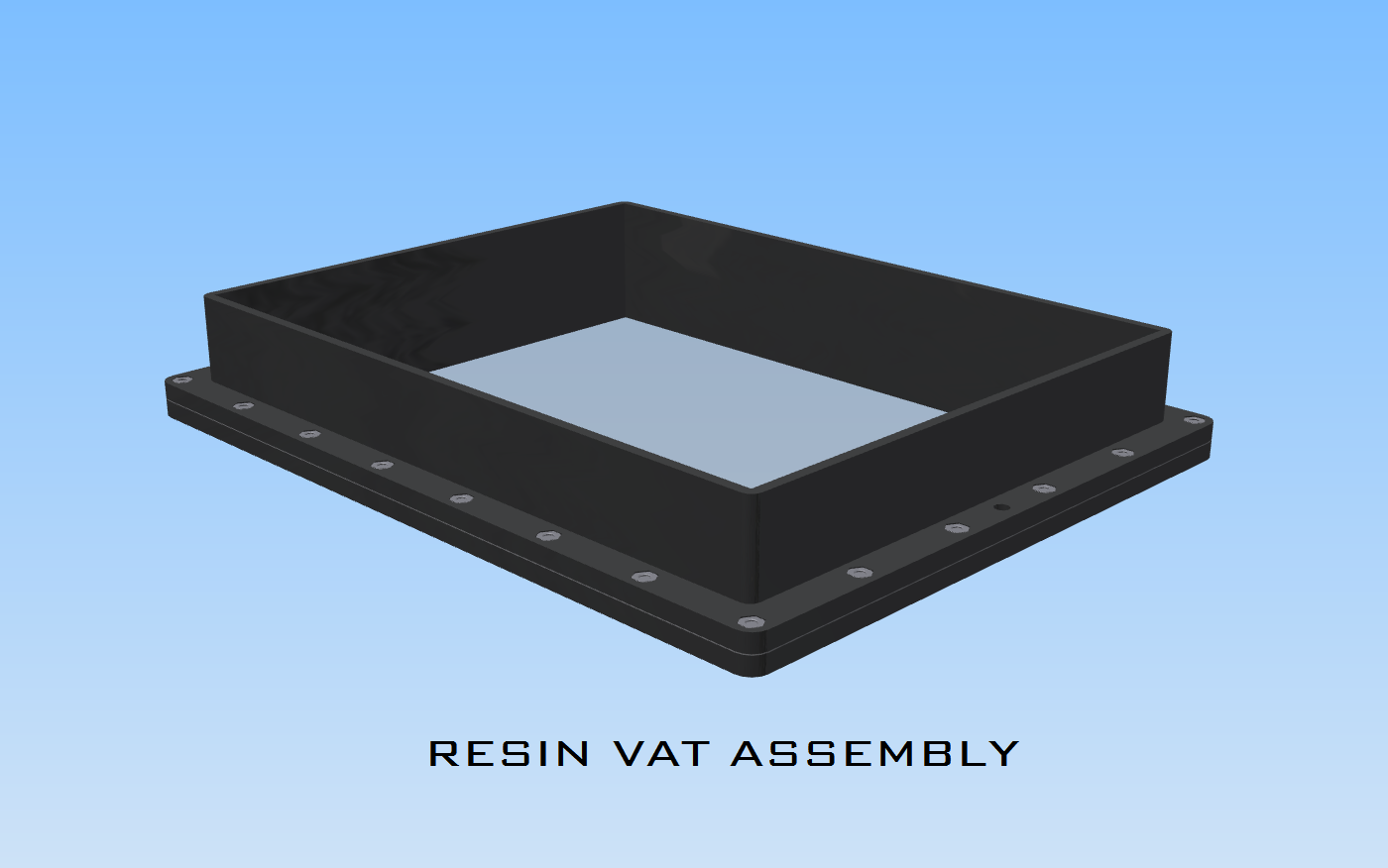

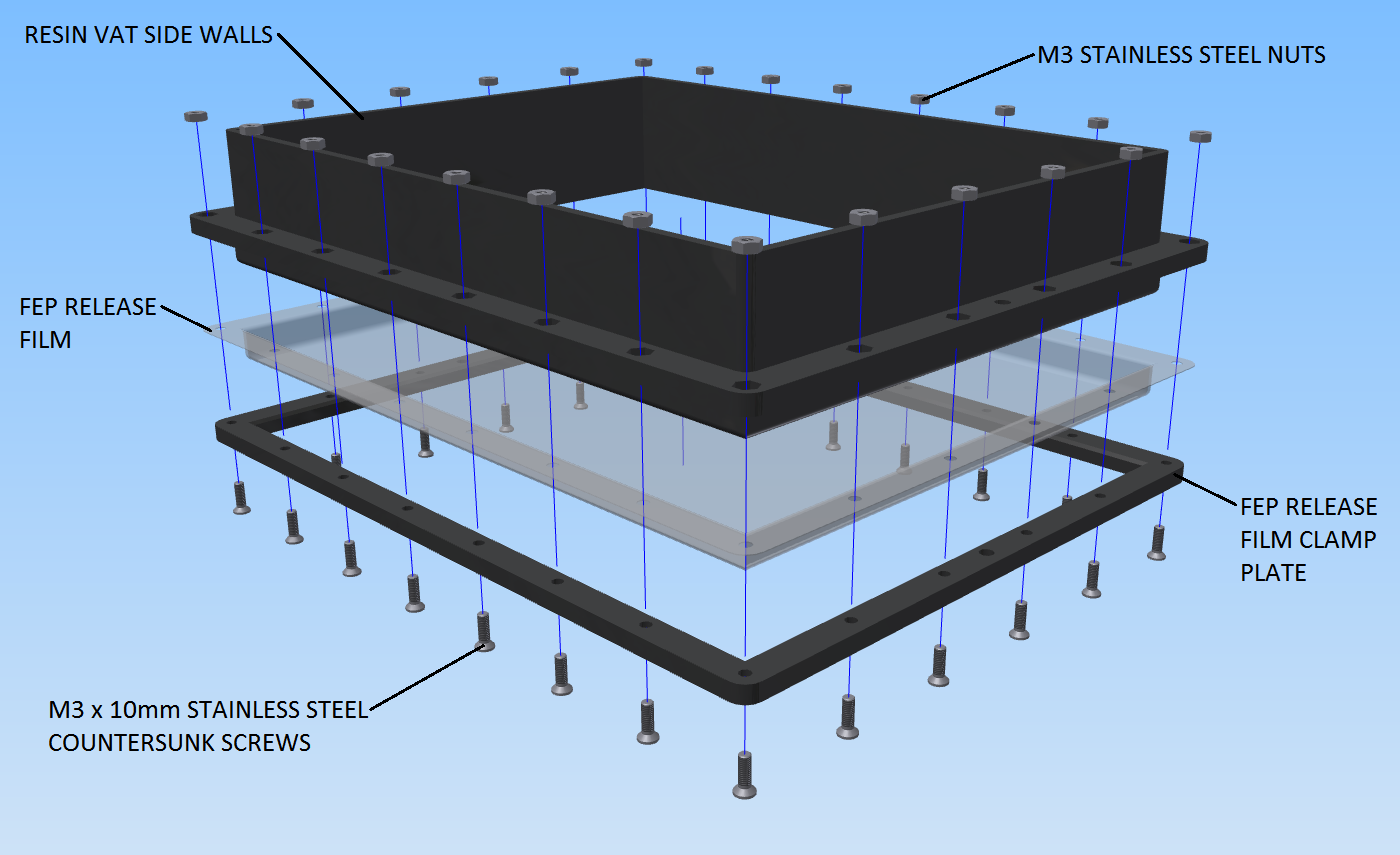

The resin vat is far more important than first glance suggests, it is not just a vessel to hold the resin such that it does not get all over the place and cause havoc! Below one can see the construction of the resin vat...

The crucial part to this assembly is the bottom floor of the vat which is made up of 0.3mm FEP film (Fluorinated Ethylene Propylene). Since this is the window to the soul of the printer, there are three properties of the FEP film that are important:

- UV and White light tranmissibility

- Releasability

- Flexibility

Since this version of the printer is an experimental platform it will accommodate both UV and White light sources. Thus the transmissibility of the light source is important, affecting both exposure and curing times.

Releasability and flexibility work hand in hand. Some printers incorporate a tilting vat to peal the most recently cured layer from the bottom of the vat. This helps to prevent the printed object from being pulled off the build platform and thus preventing a print failure. Using a flexible film eradicates the need for a tilting mechanism because as the print is rising after exposure, the film will deflect causing automatic pealing from the outside of the layer section toward the inside of the section.

The FEP film is a consumable of the the printer, for which testing must be done in order to determine life span.

The general idea for the construction of the resin vat is to sandwich the FEP film between the Clamp Plate and the Vat Side Wall flange allowing for even tensioning of the film as the fasteners are fastened.

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.