In trying to make the machine more presentable, the joystick cover plates will be powder coated black. The Harbor Freight powder coat gun was used. This was used on the Claw solenoid housing in the past. It came out looking nice, so I figured I would use it for the joystick also. Here is the gun that was used:

The cheap tote powder coat room:

And oven with wheels to moved it around:

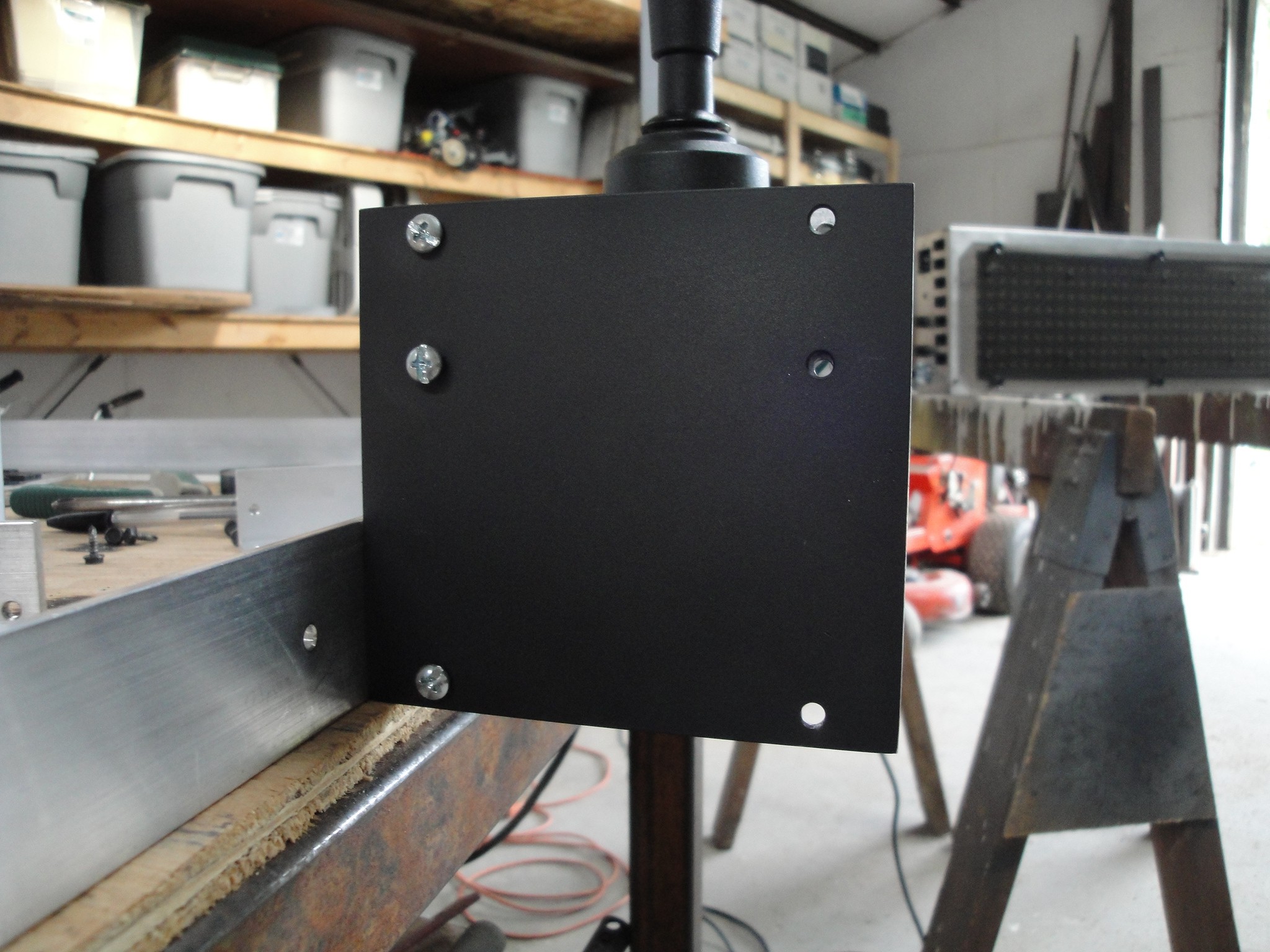

Here is the finished product waiting for other panels to be mounted along side:

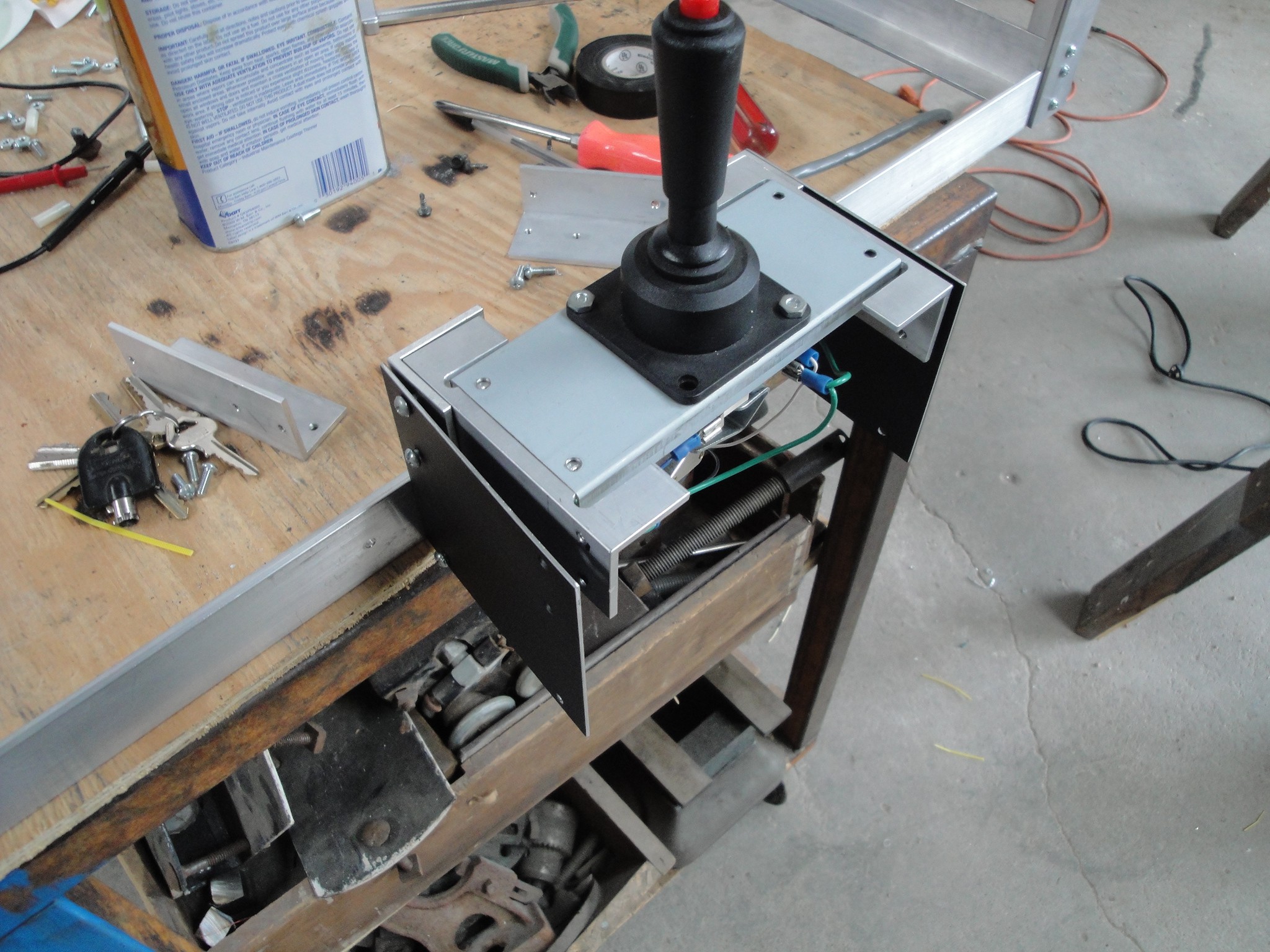

This is a pretty easy process, but this time I had a problem with clumpy powder coating, not enough coverage giving it a dry look and not completely covering the edges. Here is a breakdown of what I did:

Clumps - Wiped off the part, cleaned the surface again with alcohol and reshot the part with powder. Then placed it in the oven.

Not enough coverage - After seeing the part after it had been in the oven, I reshot some more powder coat on the part after it was cool. After the second round of heat, the part appears to look better. We will see how this affects long term abuse.

Edges not covered - Instead of reshooting the edges, I just took a file to them. This stripped the edges of powder coating and added a detailed sharp edge. Once the other parts are done, it should make the edges stand out and give a good look.

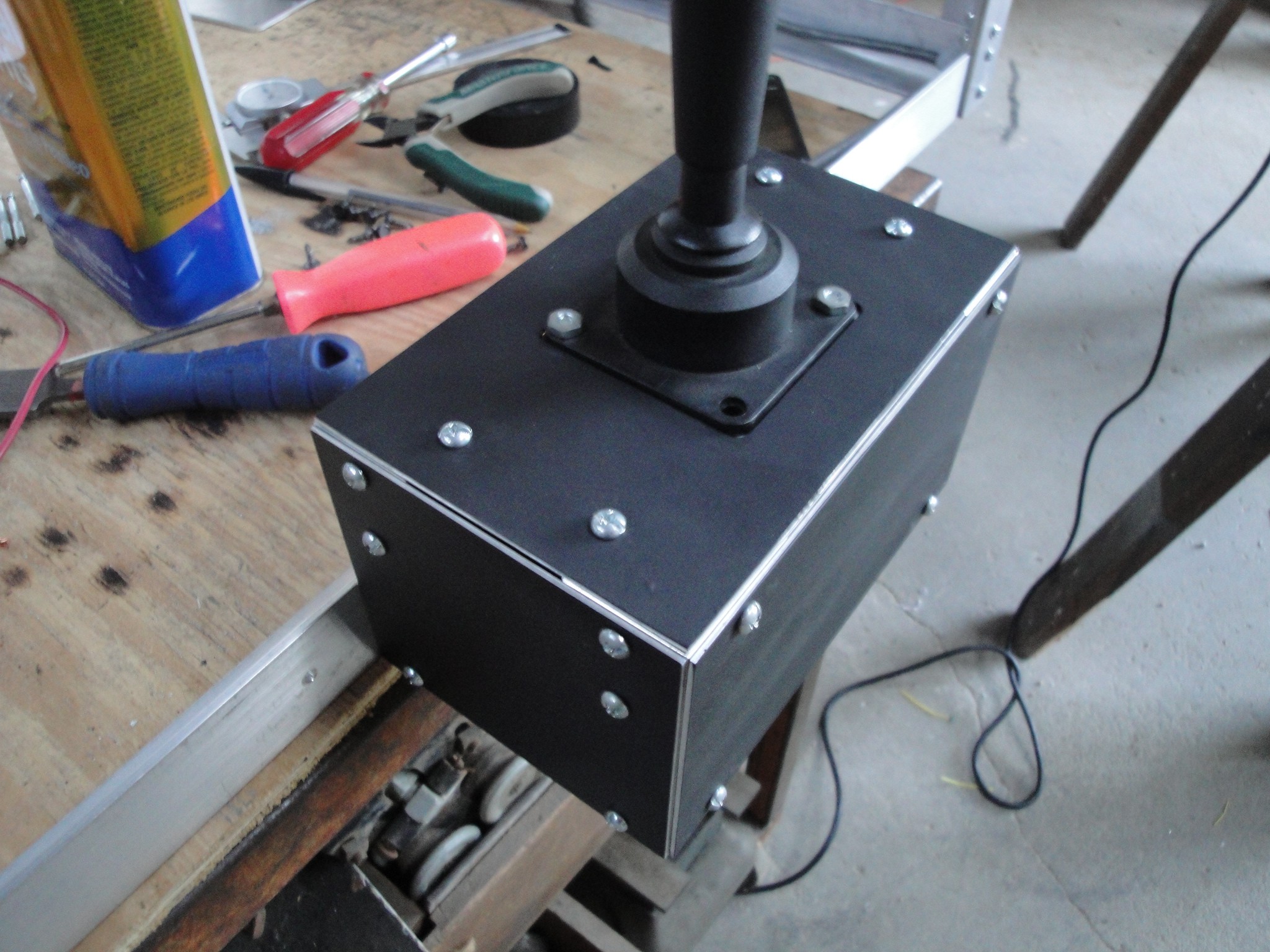

Here is the finished product:

The top and front larger panels were the ones that were shot twice. The one drawback is it caused the panels to have a rough or dry feeling to them instead of a smooth surface.

All that is left with the claw machine is re installing the plexi glass and cleaning up parts of the machine.

willbaden

willbaden

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.