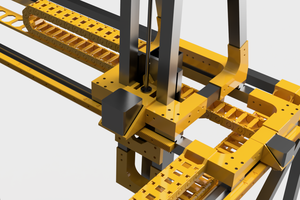

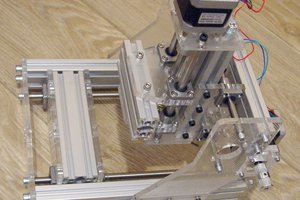

What ? My biggest project. It's a 1000x500x80mm CNC router.

Why ? Different tools can be set on the machine (laser, spindle, plasma torch, cutter etc.) and so it offers a quantity of possibilities for anything fabrication!

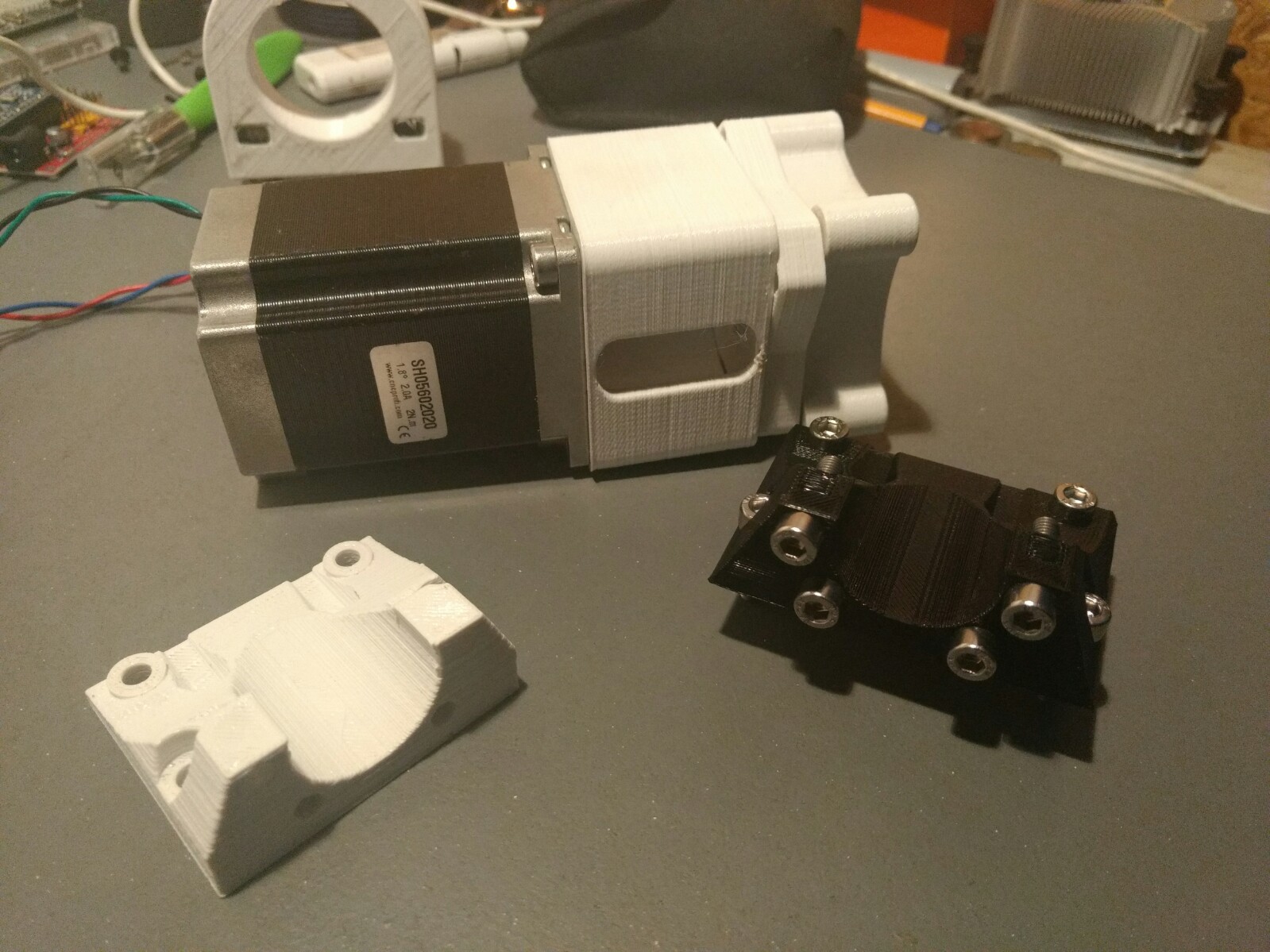

How ? I'm currently building the mechanical function. I use standard BOSCH 30x60mm Aluminium profiles for the structure. Axis motions are made through ballbearing screws. I designed brackets for NEMA23 stepper motors and 3D printed them. As soon as machine is operational, first machining shall be these pieces, easy to print still strong, but with expected short life duration. I am constantly updating design along the building.

NPN

NPN

phil

phil

Brian Brocken

Brian Brocken

BlueFlower

BlueFlower

Rui Caldas

Rui Caldas

Recommend a perfect axis drive stepper motor and driver.

Frame Size: 57 x 57mm (Nema 23)

Body Length: 76mm

Motor Type: Bipolar Stepper

Step Angle: 1.8 deg

Holding Torque: 1.9Nm(269oz.in)

Rated Current: 2.8A/Phase

Holding torque: 1.9Nm

Stepper motor:

https://www.motiongoo.com/index.php?route=product/product&product_id=106&search=23HT30S4280

Driver:

https://www.motiongoo.com/index.php?route=product/product&path=59_95&product_id=228