I got my vacuum pump and started to build the vacuum chamber.

I got my vacuum pump and started to build the vacuum chamber.

I started with a marmalade glas, LDPE pressure tube and a quick connector.

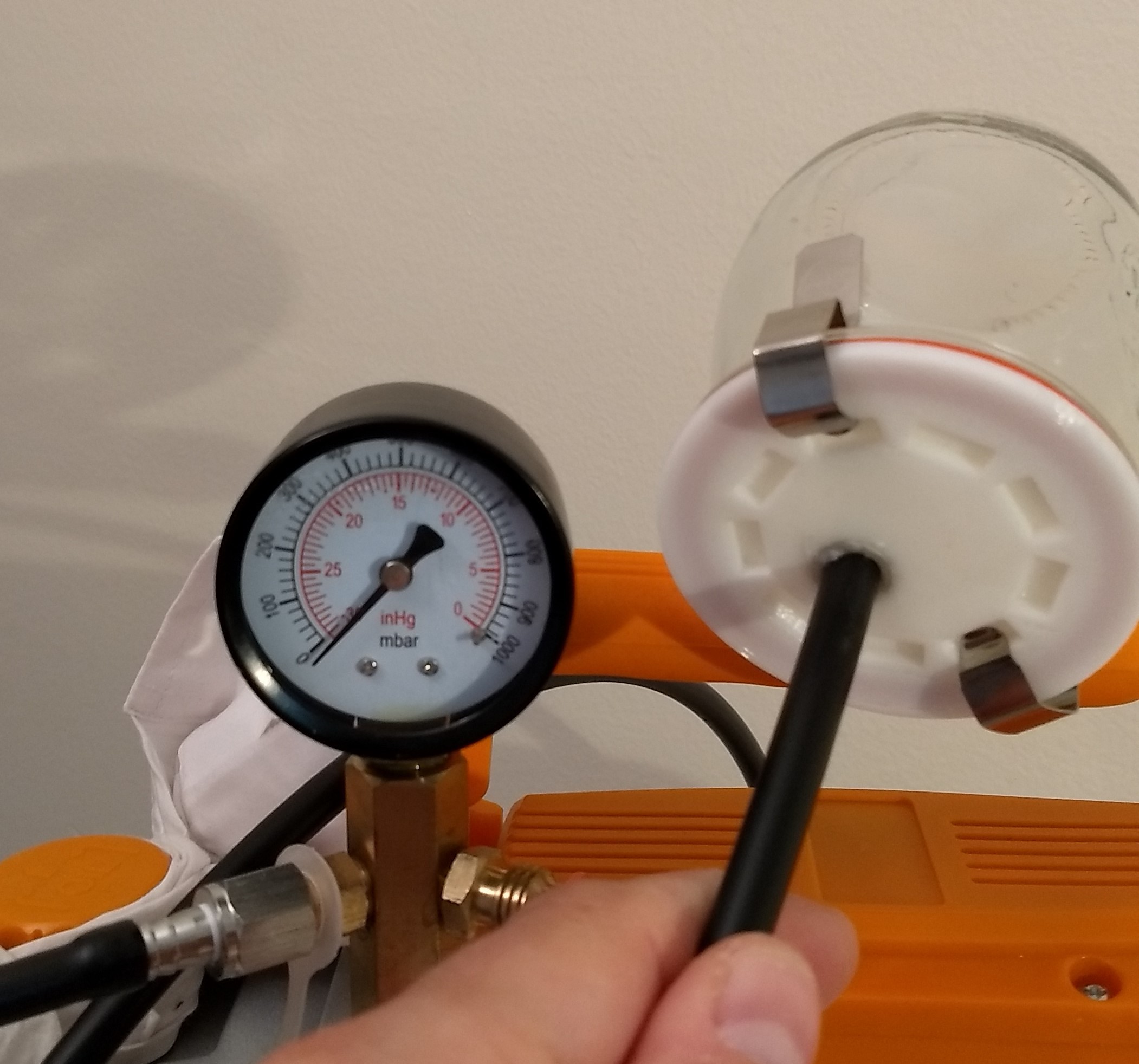

With the first printed vacuum chamber cap, the achievable vacuum was quite bad with 120mBar.

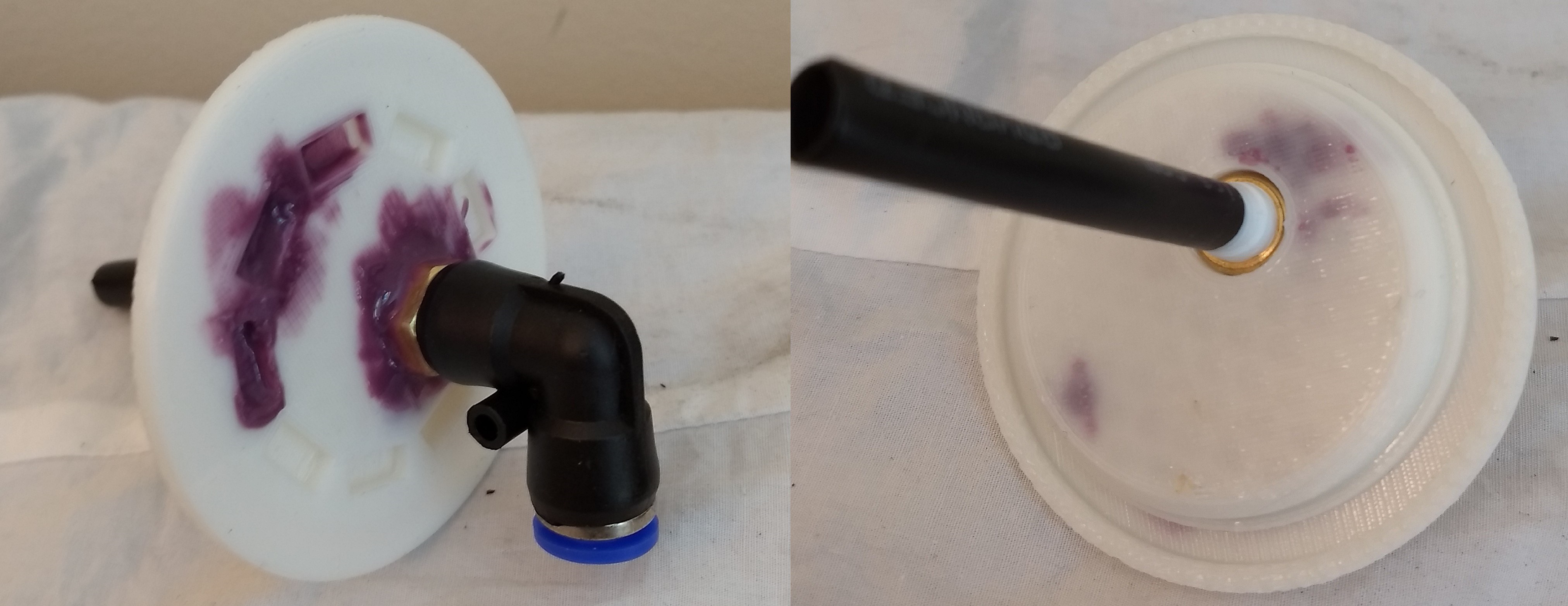

I putted colored glue on the cap, closed the vacuum chamber and started the vacuum pump. After a while I could see on the bottom of the cap the colored glue. Therefor the root cause for the bad vacuum were some small gaps in the printed cap.

Above you can see the CAD model of the cap. In this version the quick connector is replaced by a barb connection, similar to the connection between the vacuum pump and the tube.

The video above shows an accelerated print, it visible that the filling factor is 100% of the print.

To get a strong connection between the cap made of PLA and the tube made of LDPE I used a special 2K glue. The special at this glue is, that it is suitable for PE. The most other 2K glues are explicit not recommended for PE or PP gluing.

To get a strong connection between the cap made of PLA and the tube made of LDPE I used a special 2K glue. The special at this glue is, that it is suitable for PE. The most other 2K glues are explicit not recommended for PE or PP gluing.

The image above proofs it, now all looks tight.

Chris.deerleg

Chris.deerleg

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.