A crucial feature is that the resolution of the scanner should be better than 100 micrometers. I measured the prism today and the lines generated by different facets do not overlay each other. Although, I thought I had solved this. Luckily a business contact clarified it, link.

I quote;

"One of the characteristics of a polygon scanner is cross-scan error which is a deviation perpendicular to the scan line. This is also referred to as wobble or dynamic track error. There is non-repeatable wobble error from the motor bearings. There is also repeatable error from polygon facet to datum error. There is no such thing as a perfect polygon scanner. There is always some wobble error"

Zeller stated that he also had this issue with reflective polygons, see link.

"but also different mirror faces are ever so slightly tilted up/down resulting in a forward/backward movement of the project lines in some mirrors"

There are several ways to mitigate this;

optics

collimate laser bundle with aspherical lens

focus laser into one direction with cylindrical lens

refract through prism

focus laser into other direction with cylindrical lens

This would fix a lot of issues;

- beam is more round

- wobble error is gone

software

only use one facet or correct on facet basis

This has several disadvantages;

- cannot reduce non-repeatable motor bearing errors

- speed is clipped, in case of one facet

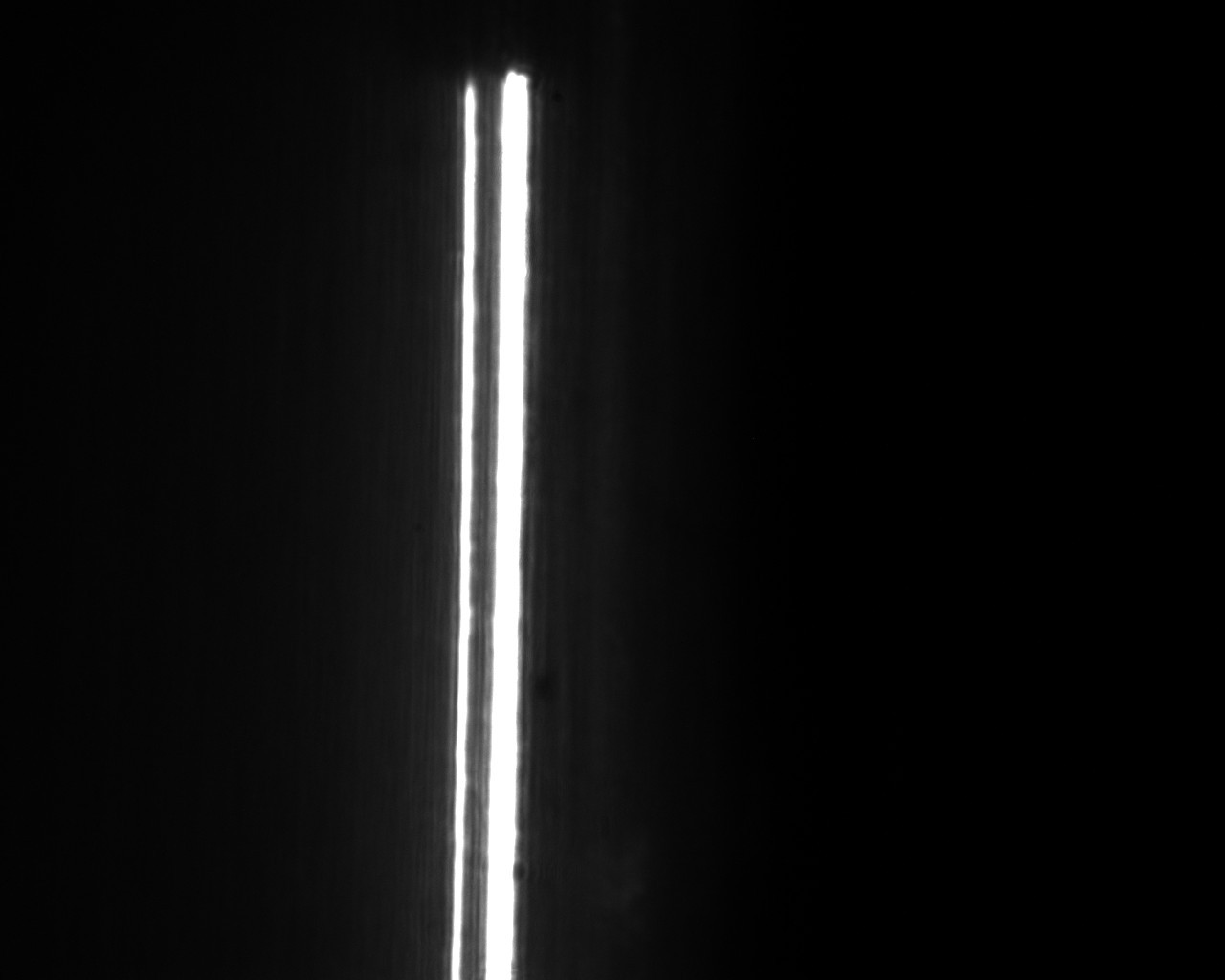

A multi facet exposure is shown below, The different facets are visible.

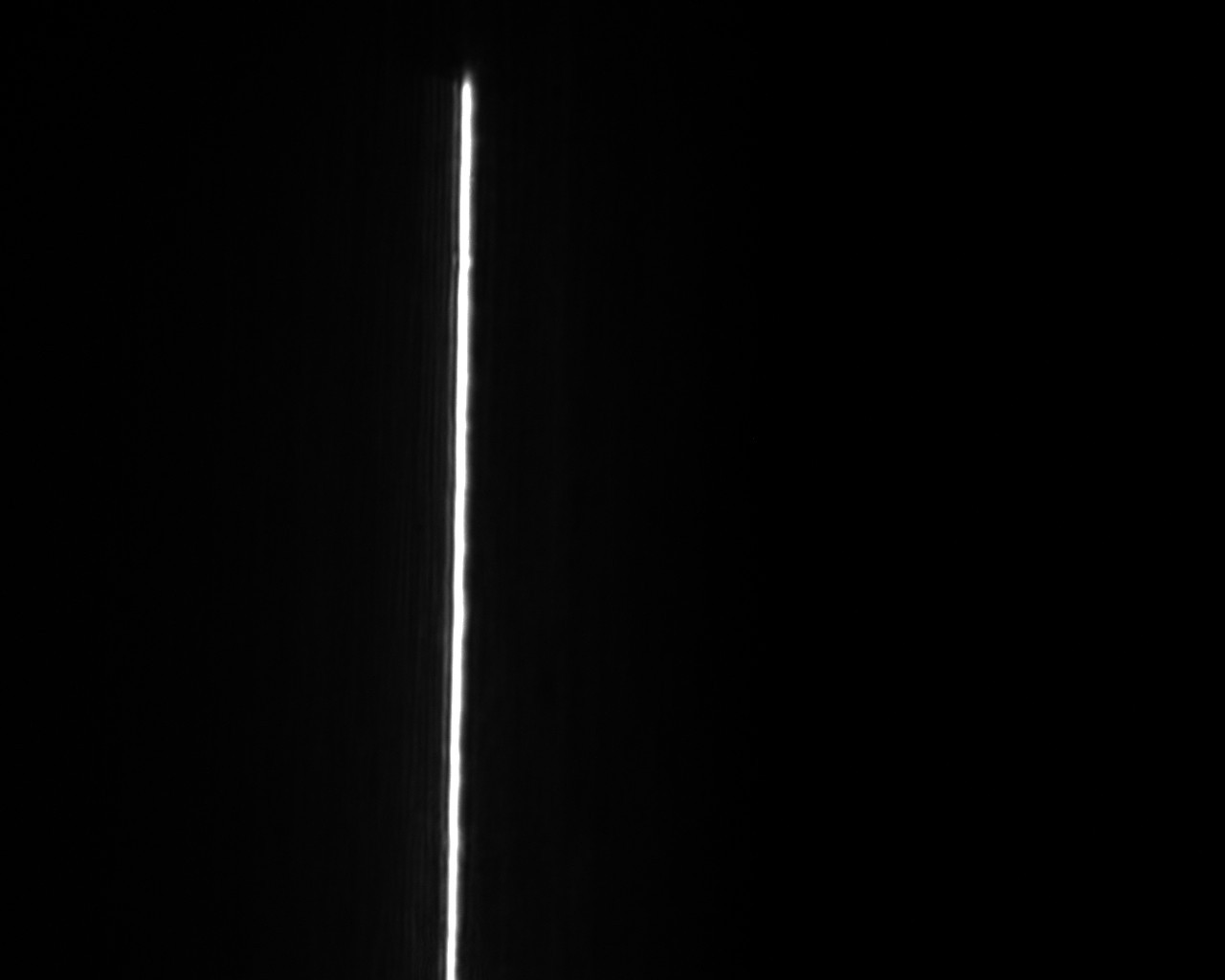

This is fixed in the software by enabling only one out of four facets.

Hexastorm

Hexastorm

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.