We wanted to do some rough simulation of our Polyoxymethylene (Delrin) bearings to determine if they can handle the pressure we expect under load! So,.. I learned how to operate SimScale over the course of the last week. Simscale is a rather easy to operate web-based mechanical engineering simulation program.

We compared our current prototype bearing profile with a hypothesized newer profile with potentially better stress relieving attributes.

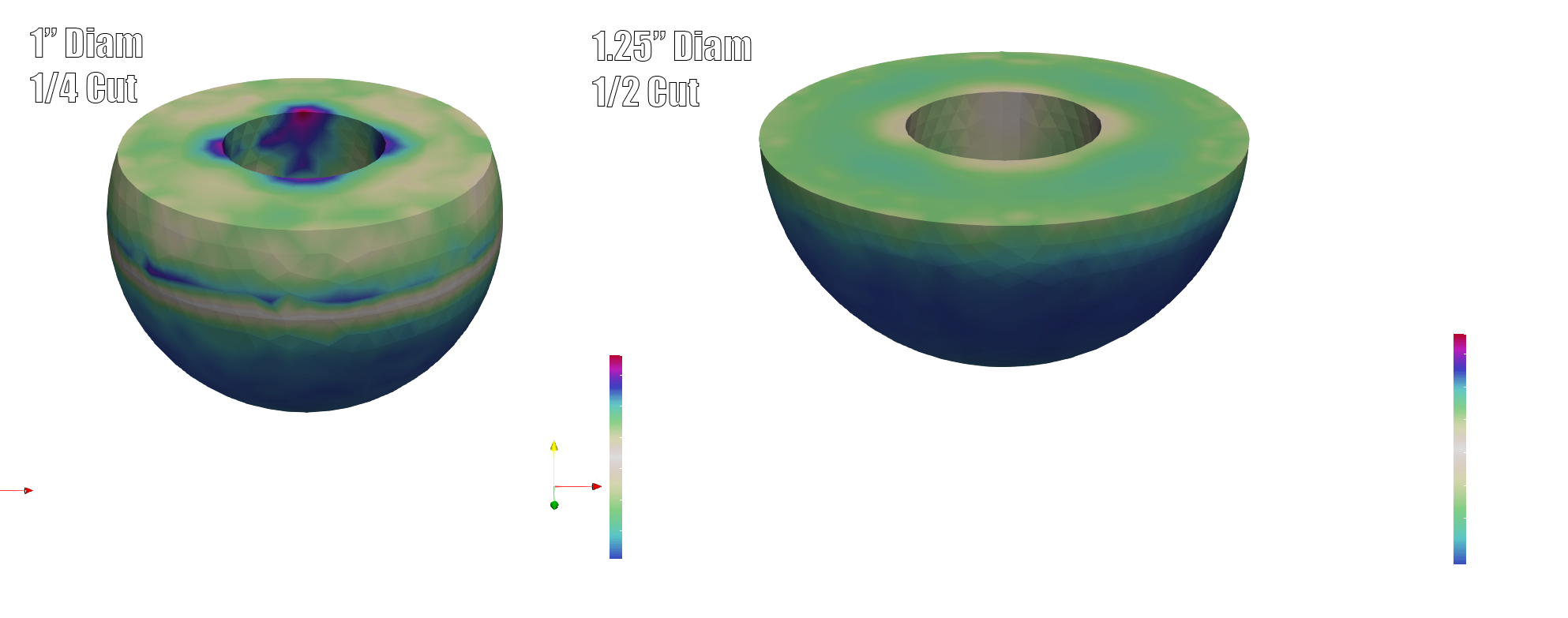

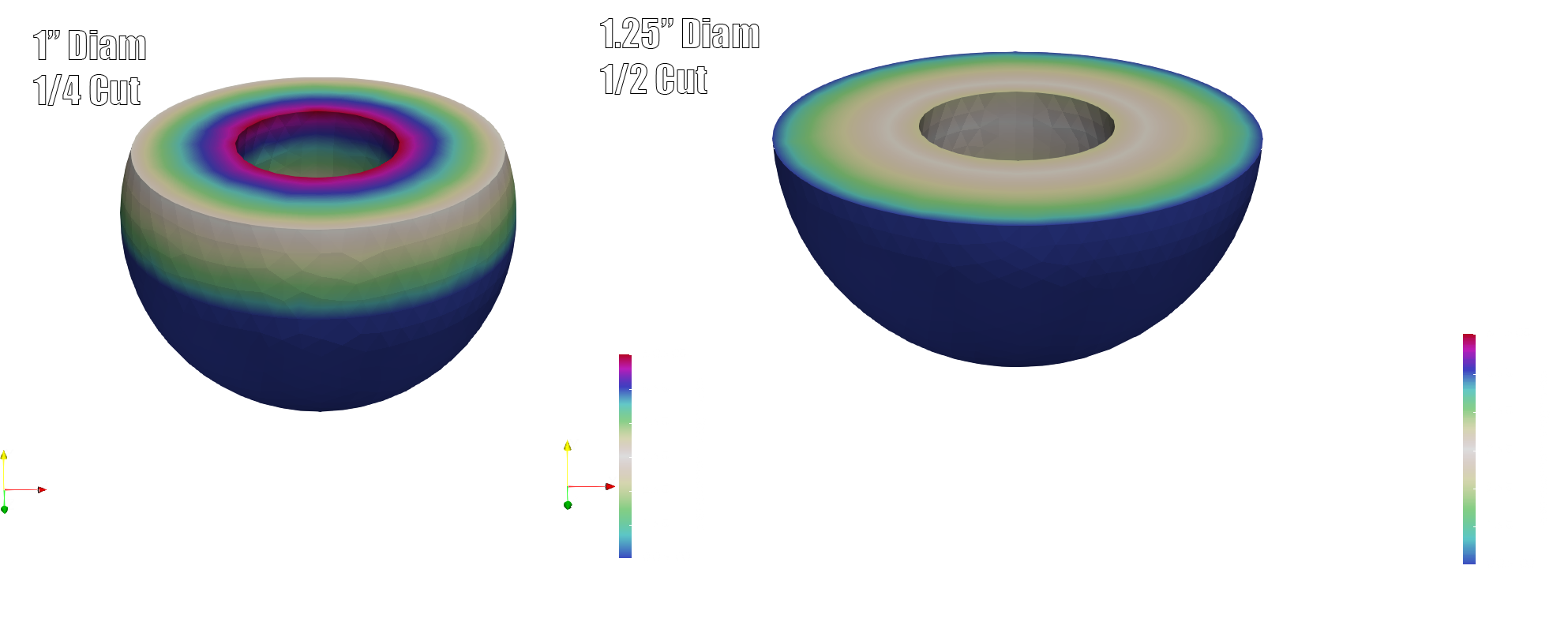

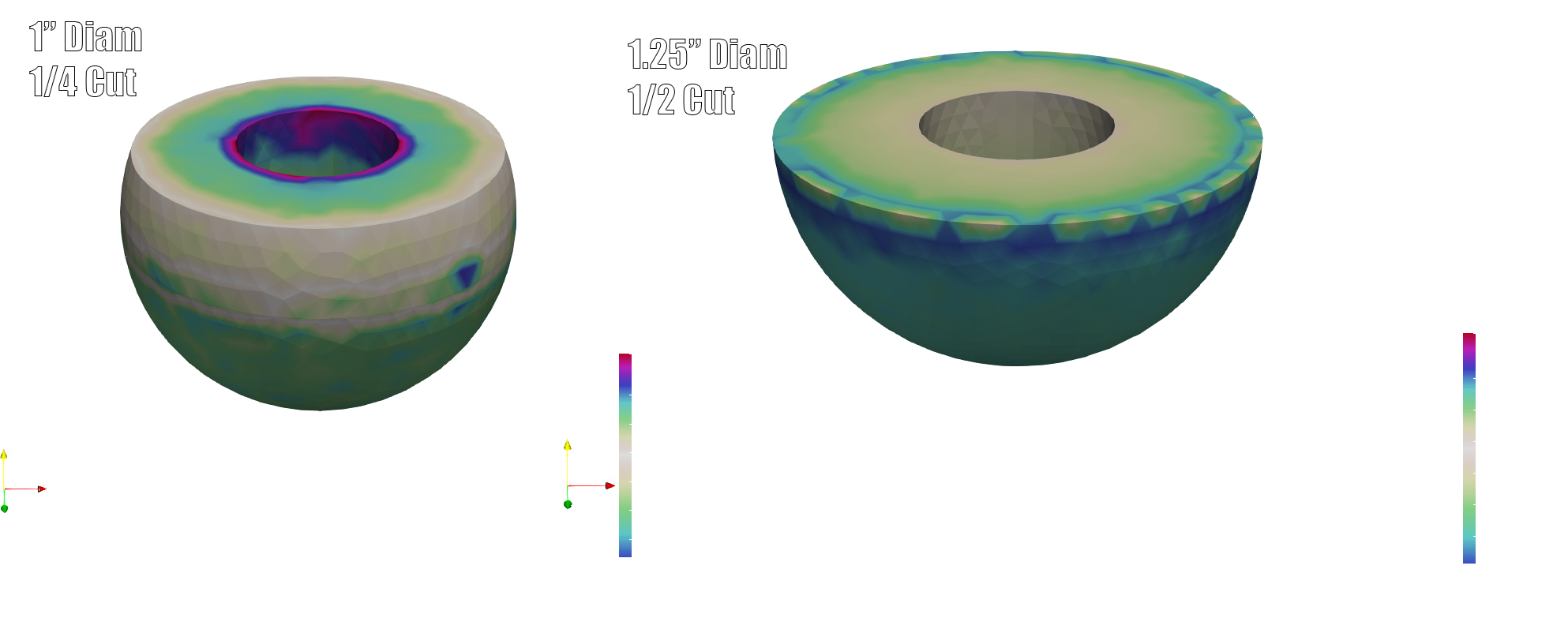

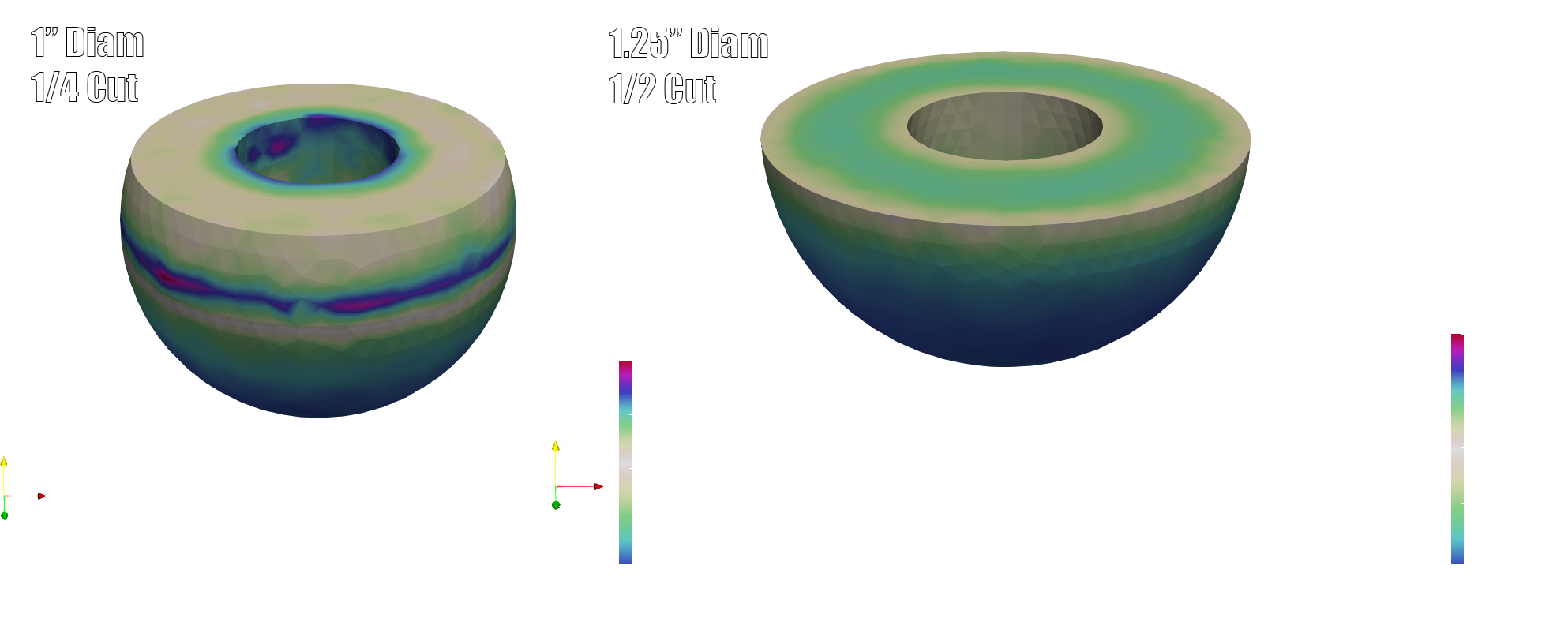

Simulation #1) Current Bearing Profile. 1" Diameter.. Cut 1/4 off at the top.

Simulation #2) Hypothesized Profile. 1.25" Diameter.. Cut halfway through.

Polyoxymethylene--

Young's Modulus: 3.1*10^9 N/m^2

Density: 1,410 kg/m^3

Poisson's Ratio: 0.44

Applied force: 2,000 lbs Normal to flat face.

Constraints: Round support structure cradling bottom half of bearing

Total Strain [m/m]

Notes: A majority of the strain appears to be forming above horizontal diameter.

Displacement [m]

Notes: Any surface area not supported is experiencing some displacement. This is a good argument for the half-ball rather than the full 3/4 ball we have now.

Cauchy Stress [Pa]

Notes: Cauchy stress indicates the stress experienced during displacement.

von Mises Stress [Pa]

Notes: Now this is the plot we're really interested in! The VM stress plot will tell us whether our bearing will break under load. The 1/4 cut 1" ball results in a peak VM stress of approx. 3,000 psi whereas the 1/2 cut 1.25" ball results in peak stress of approx. 2,000 psi.

Conclusion-- The compression strength of Delrin is approximately 5,000 psi. Our current setup may be getting a little too close to that number for comfort. Cutting the ball in half certainly reduces strain. Increasing the bearing size certainly increases our ability to disperse applied stress.

Greg Stephens

Greg Stephens

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.