-

The Maker Faire

05/23/2017 at 17:29 • 2 commentsWe're back from our 1300 mile (round trip) expedition to this year's Maker Faire in San Mateo, California.

..and boy are our feet tired!

![]()

Alex and I wanted to explore the maker community, and we weren't disappointed! There are a lot of you out there. And, you're making some really cool things. This has strengthened our resolve to expand what our fellow makers can make. Follow us, we may be announcing a new project very shortly.

![]()

-

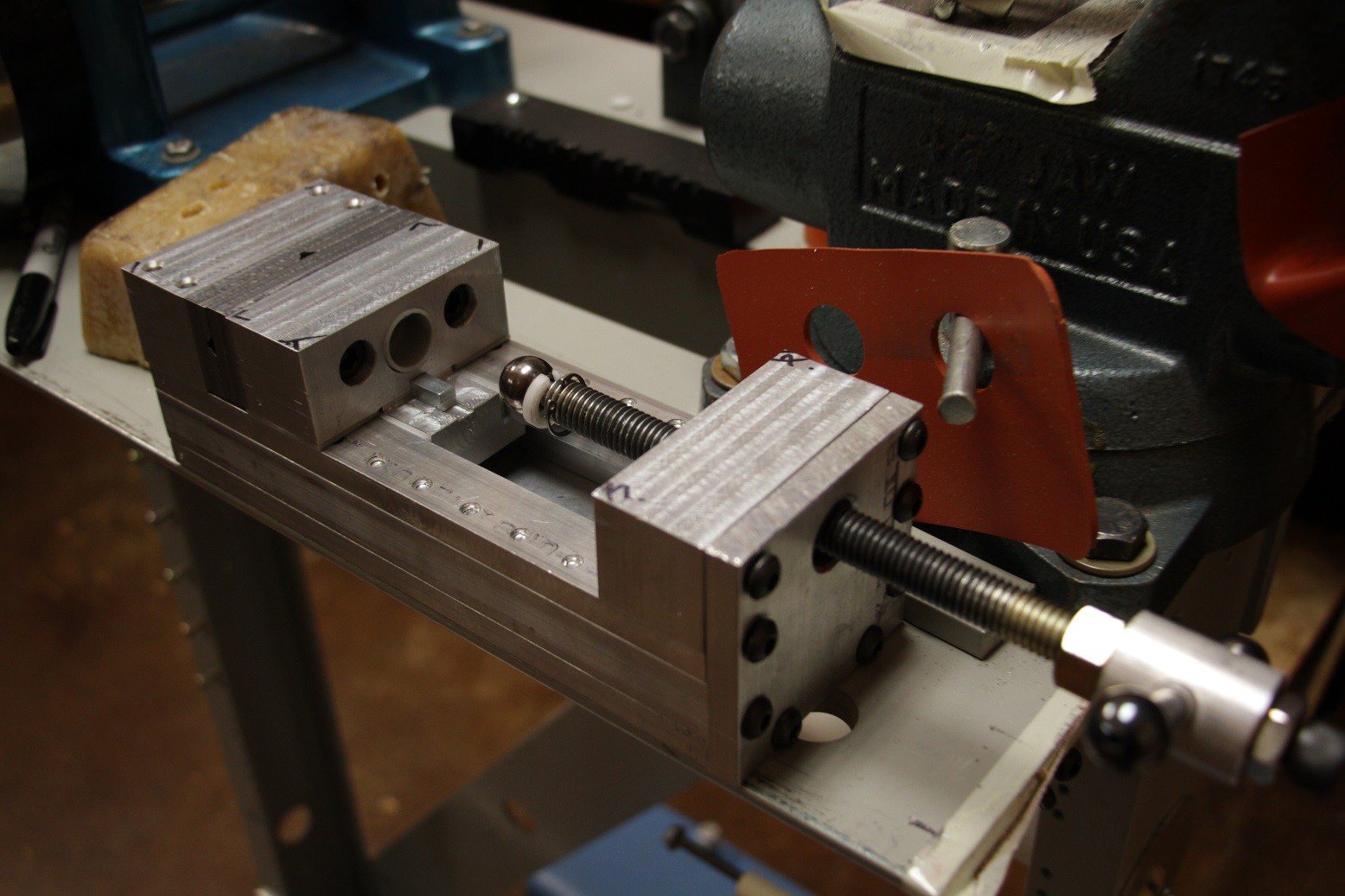

How to Put Your Balls in a Vise

05/19/2017 at 04:31 • 1 commentToday was the last day we had to prepare for the Maker Faire in San Mateo, California.

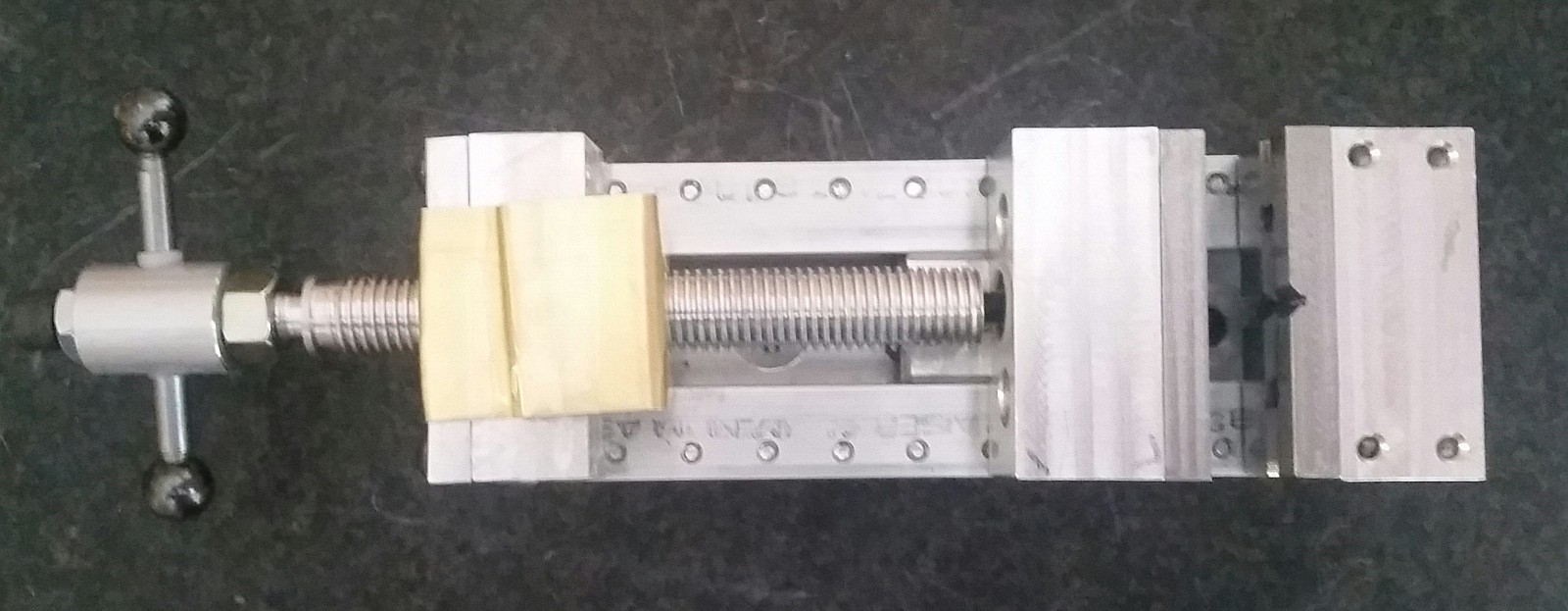

We do not yet have our 3D printed jaw sets!! So, Alex reduced a stick of polyethylene into an acceptable ball-holding shape.

![]()

"Unfortunately our balls are a bit large to comfortably hold in the vise." ~Alex

But, this new jaw set will show off our concept of holding unique objects with customized soft jaws.![]()

-

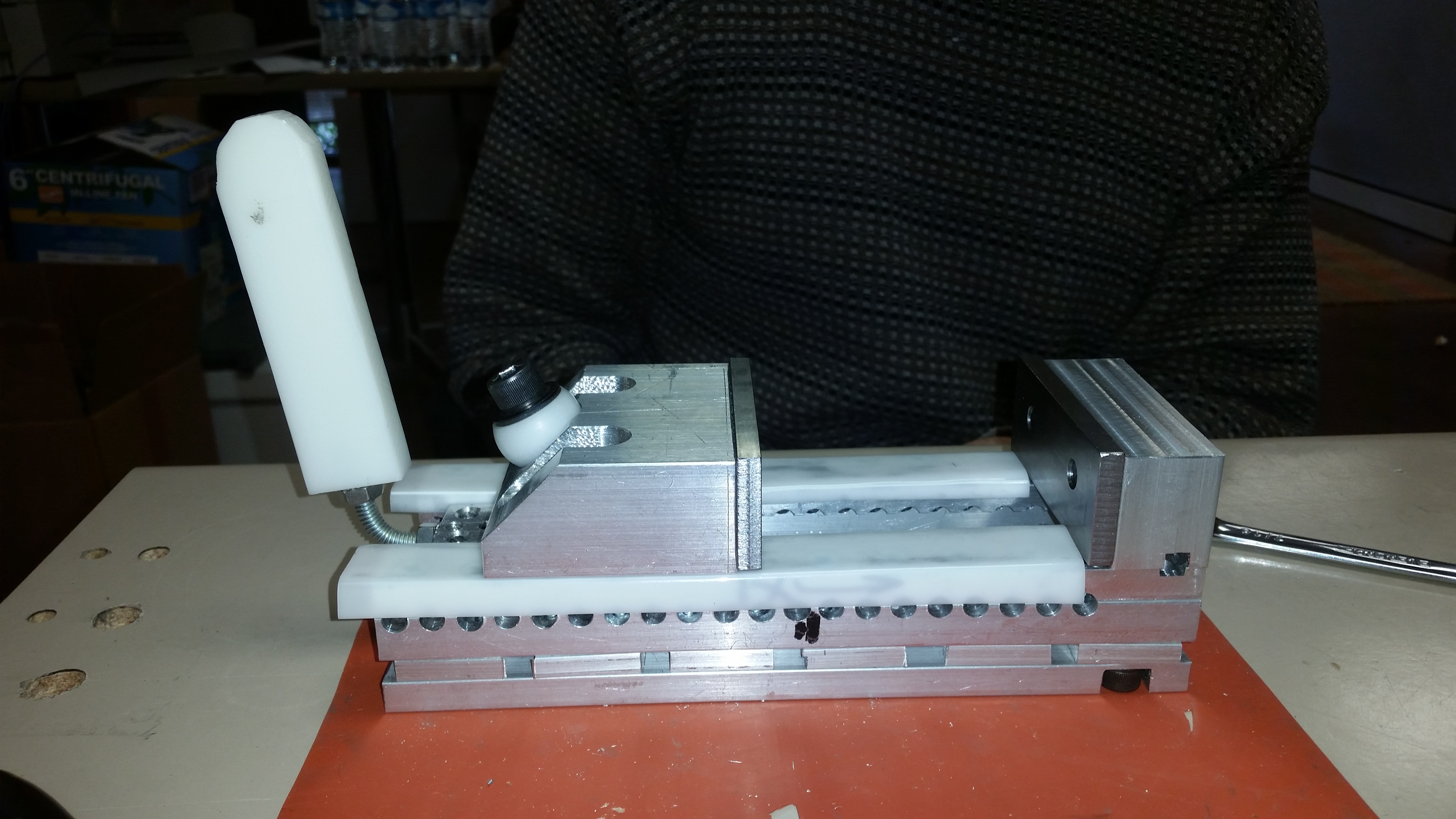

Clean Jack Screw.

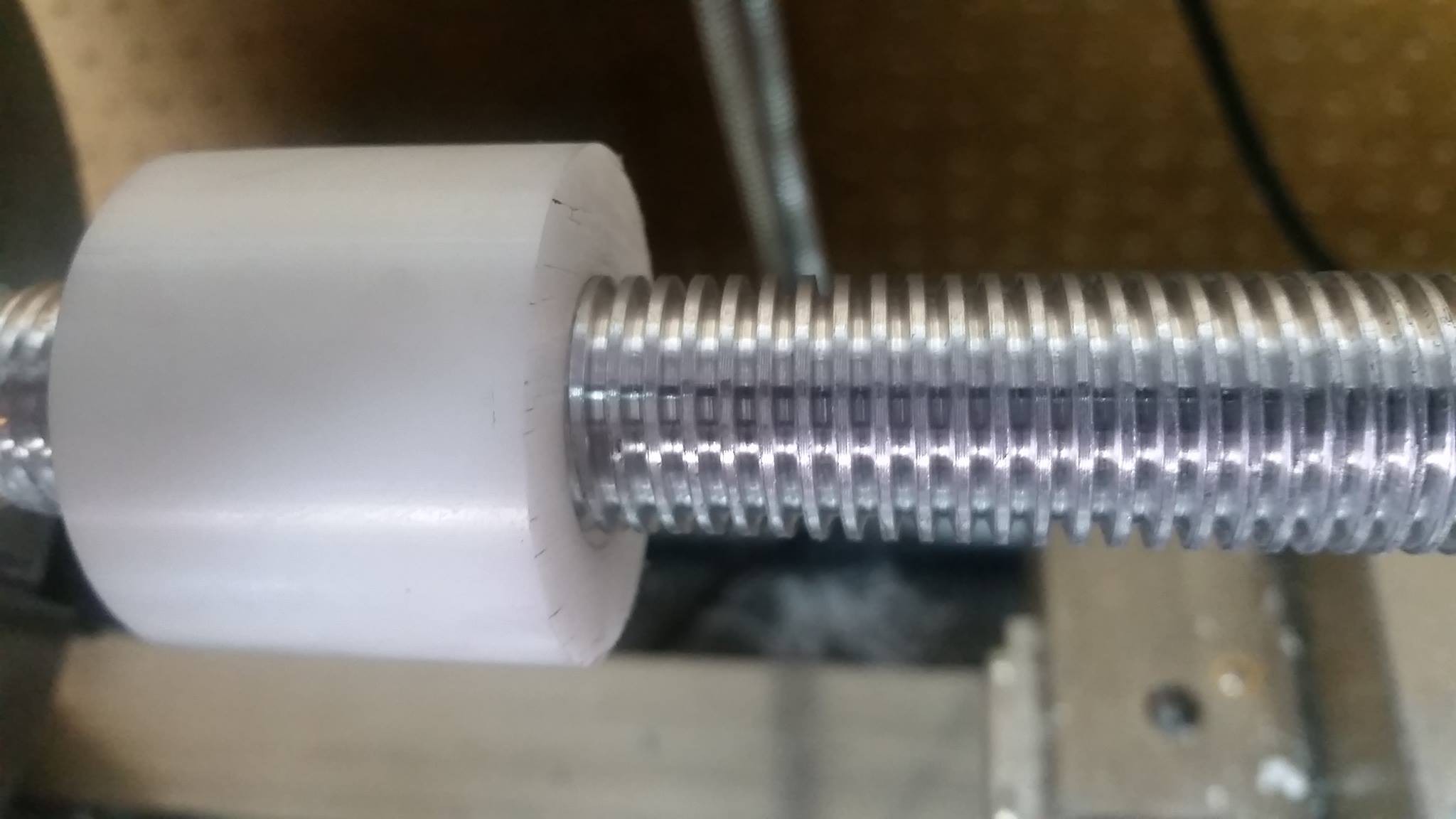

05/18/2017 at 17:57 • 0 comments(update 2017-5-23) Here's prototype 2, (maybe 2.5) with the clean jack screw installed. The nut retention leaves a lot to be desired, it was hacked from piece of brass early morning in a hotel room. (yes, I cleaned up the little sharp nibblings.) Works pretty good! I can crank this as tight as I can without damaging the nut.

![]()

Something that may be useful to others... the little balls on the end of the crank are actually 0.625" diameter 1018 steel balls from mcmaster. They are case hardened, so I have to temper them down, turning them a blueish black in the process, to be able to drill and thread them. Attempting to drill hardened bearings w/o any annealing was a high density learning experience a few weeks ago. The blueish black (yeah the same sort of thing for "gunmetal blue finish" is coming from ferrite.. an iron oxide that forms at particular temperatures. (another project to be posted shortly uses this)

There's also a threaded ball used for a balljoint that links the jackscrew to the slider. I used 5/16-24TPI thread because it's nice and I have a good tap for it. All this stuff was made on the Smithy.

-------------

Aluminum jack screw and Delrin nut. 0.75 x 12 TPI. (I kinda copied my lathe's lead screw dimensions. There's also an awesome ACME thread calculator on http://www.engineersedge.com/hardware/acme-threads-calculator.htm that I used.

I wonder if the ACME thread would've got so popular without Wiley Coyote. Took a long time compared to what a 60deg thread would have taken me. But I think it'll be a much better system in the plastic than a 60 deg thread.

Everything I can prototype on the manual machine at home should be easy and cheap to make on a CNC mill and turning center. The aluminum will eventually be anodized.

Some day I want to get hold of a more torquey lathe. The lathe (and mill) I'm using is a Smithy "Granite" which I put a Chinese DRO on.

![]()

-

Practical Application

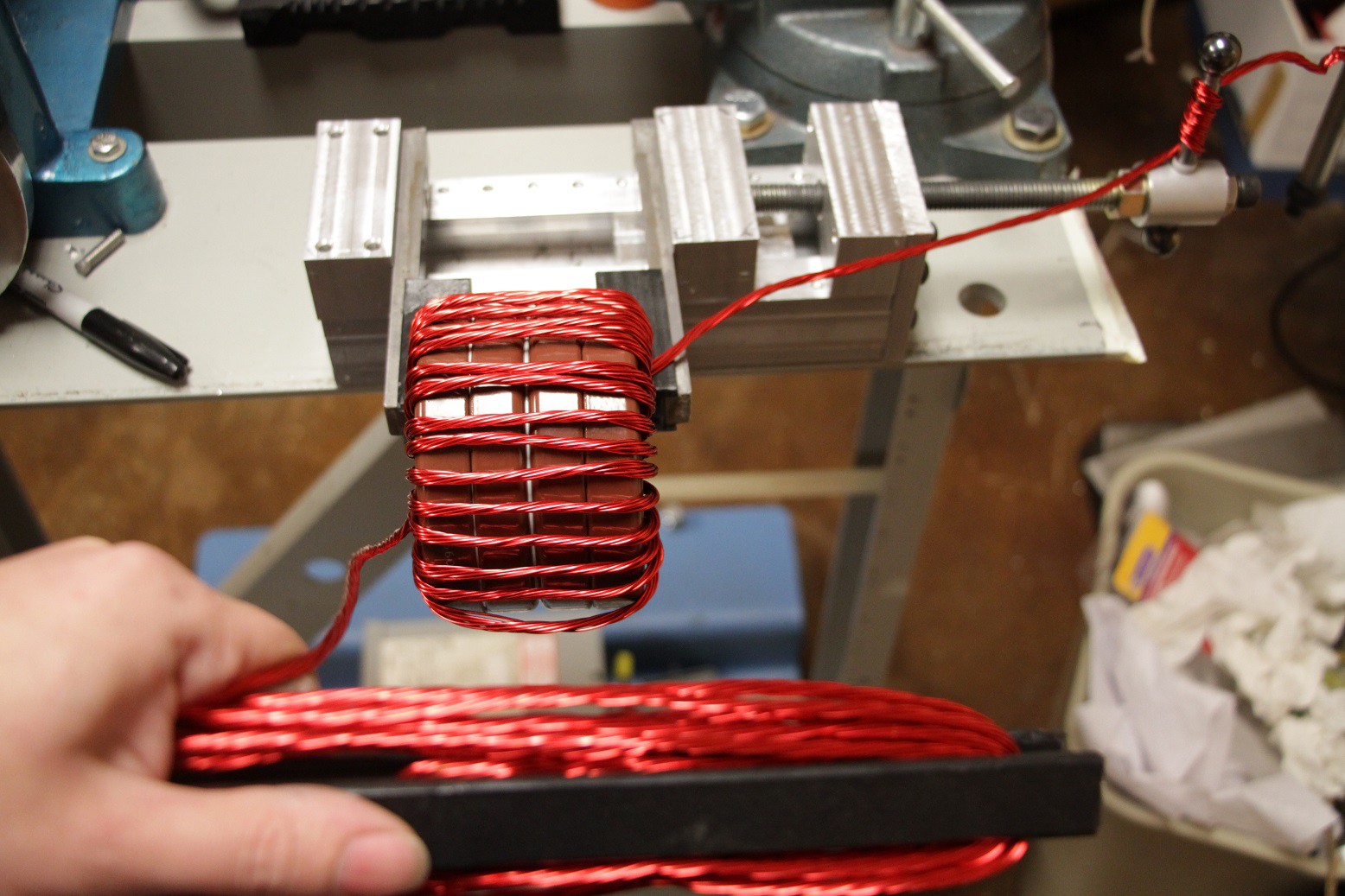

05/15/2017 at 20:17 • 0 commentsToday's agenda included winding up a toroid inductor. This is a notoriously time-intensive task.

Well,... our Maker Vise [rev2] prototype made the job relatively painless! It is heartening to find that we are already finding our vise useful for otherwise difficult tasks.

-

Gearing up for the Maker Faire

05/13/2017 at 23:19 • 0 commentsWe wanted to show off our vise at the upcoming Maker Faire. Alex has fabricated a transparent side window to preview the inside mechanisms.

![]()

-

This is Where We Need Your Help!

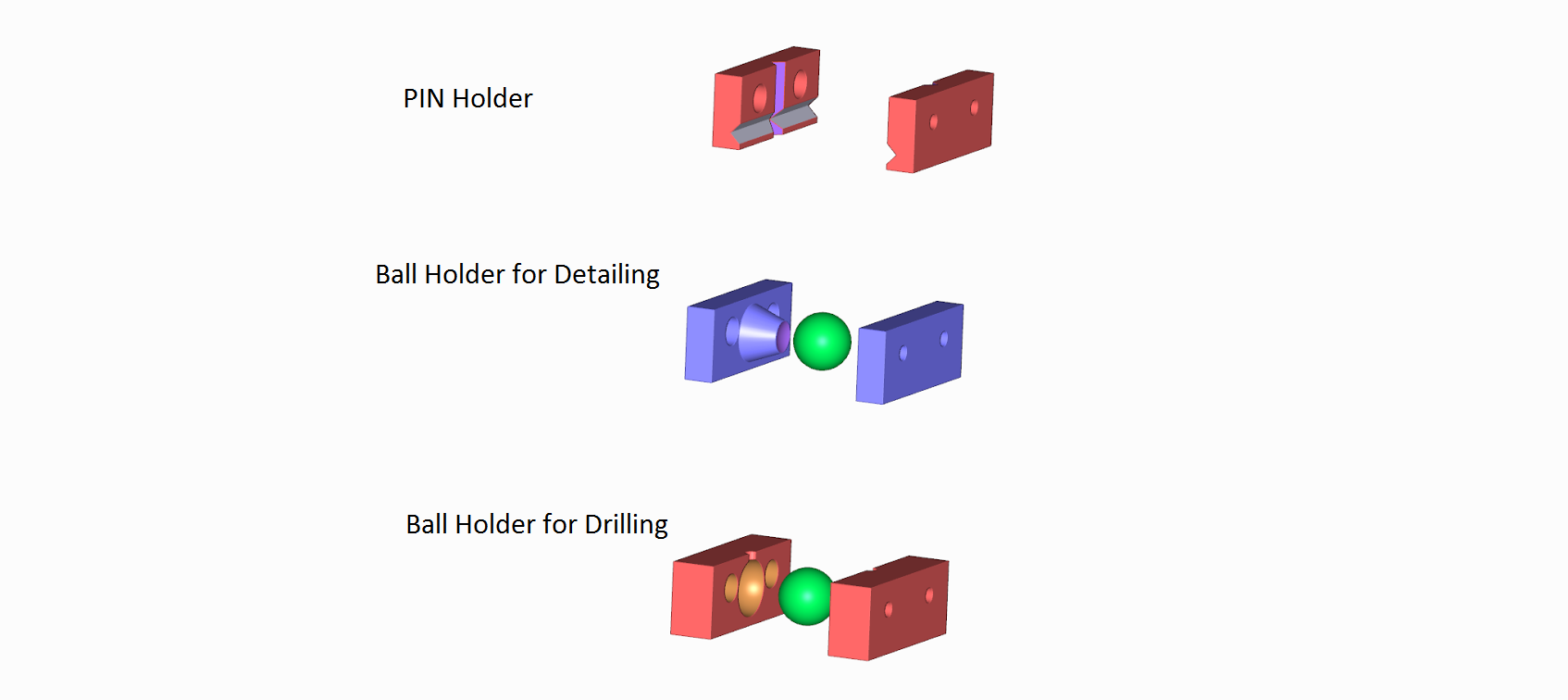

05/12/2017 at 18:30 • 0 commentsIt's time to start 3D printing some Jaw concepts!!!!!!!!!!!

We want to print and test some experimental jaw designs. We need help coming up with ideas! What jaw shape would aide your project?? ...please comment below. TY!

Here are some initial ideas we've come up with:

![]()

-

Small Update [Pull-Back Mechanism]

05/11/2017 at 23:20 • 0 commentsAs you can see, we upgraded the pull-back mechanism to a ball joint.

You may also have noticed the oil coating the through-bolt. Our next project will be to change out materials of the bolt feed-through, so that oil is no longer required.

-

Early prototype Rev2

05/11/2017 at 22:38 • 0 commentsJust got our second revision prototype together.

Without a functional pull-back mechanism... we improvised with scrap metal and hot-melt.

-

Jaw Material Testing

05/11/2017 at 22:19 • 2 commentsUsing steel bearings and a hydraulic press.. we tested the material strength of several potential materials craft the jaws from.

So far, the most attractive has been 4140 case hardened steel.

Here is what we were using to do the pressing:

![]()

![]()

-

The Scorpion (Early Prototype)

05/11/2017 at 22:07 • 3 commentsAs our first update, I would like to show how far we've come since the beginning of April. Our first prototype, we are lovingly referring to as "the scorpion."

In our attempt at forcing the sliding mechanism to work smoothly, we fabricated a scorpion tail-like handle.

In the end, the mechanical grip strength of this type of slider mechanism was lacking. And, we wanted to move on to try other types of sliding mechanisms.

![]()

Greg Stephens

Greg Stephens