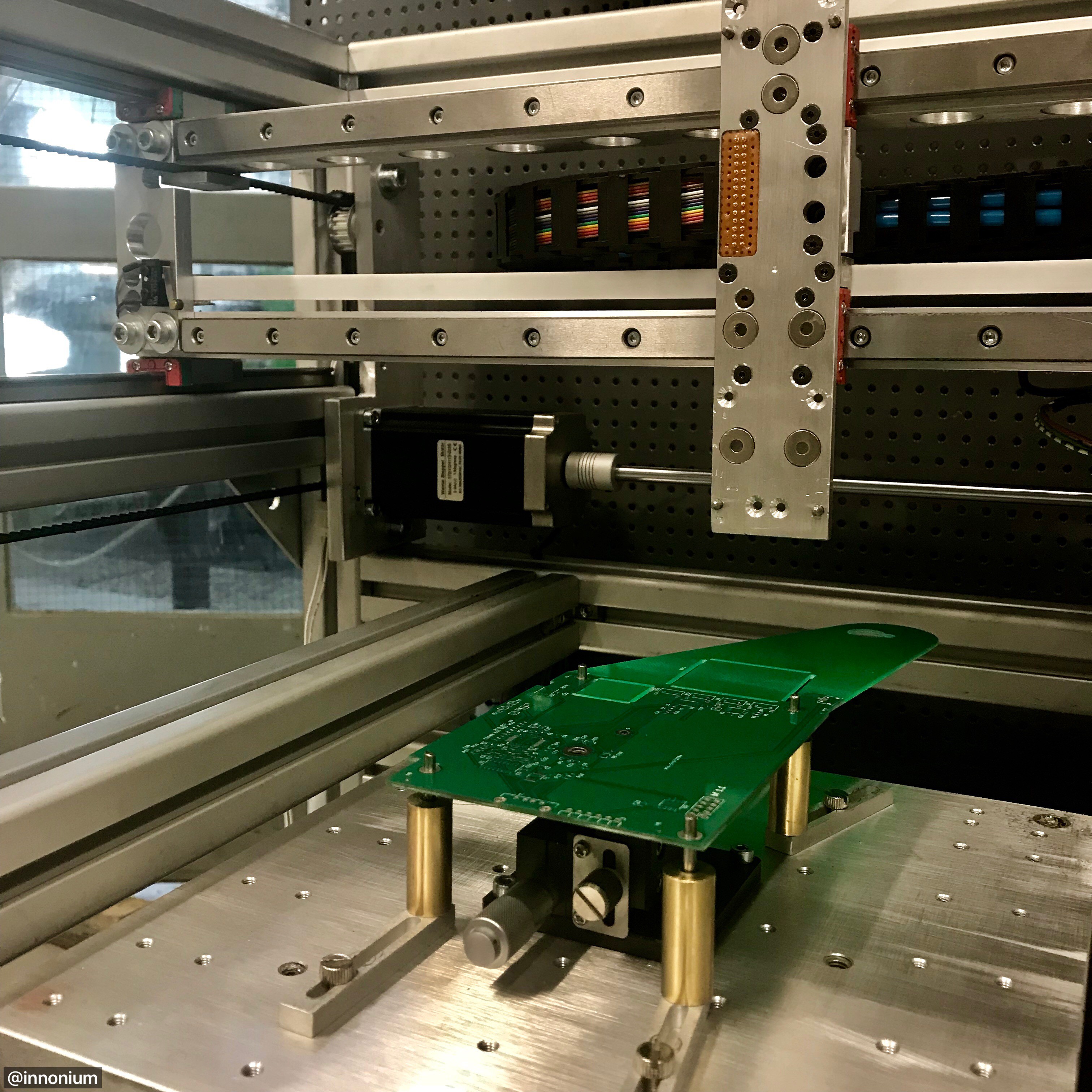

Lot of development has happened around brdMaker. One of the biggest changes has happened around the mechanics. On new mechanics all axes run on double rails to improve accuracy even more.

Biggest change has happened on the toolhead. Whole toolhead is designed for quick replace. brdMaker can even replace toolhead on the fly.

Pick and place toolhead is optimised for size and made compatible with quick connection.

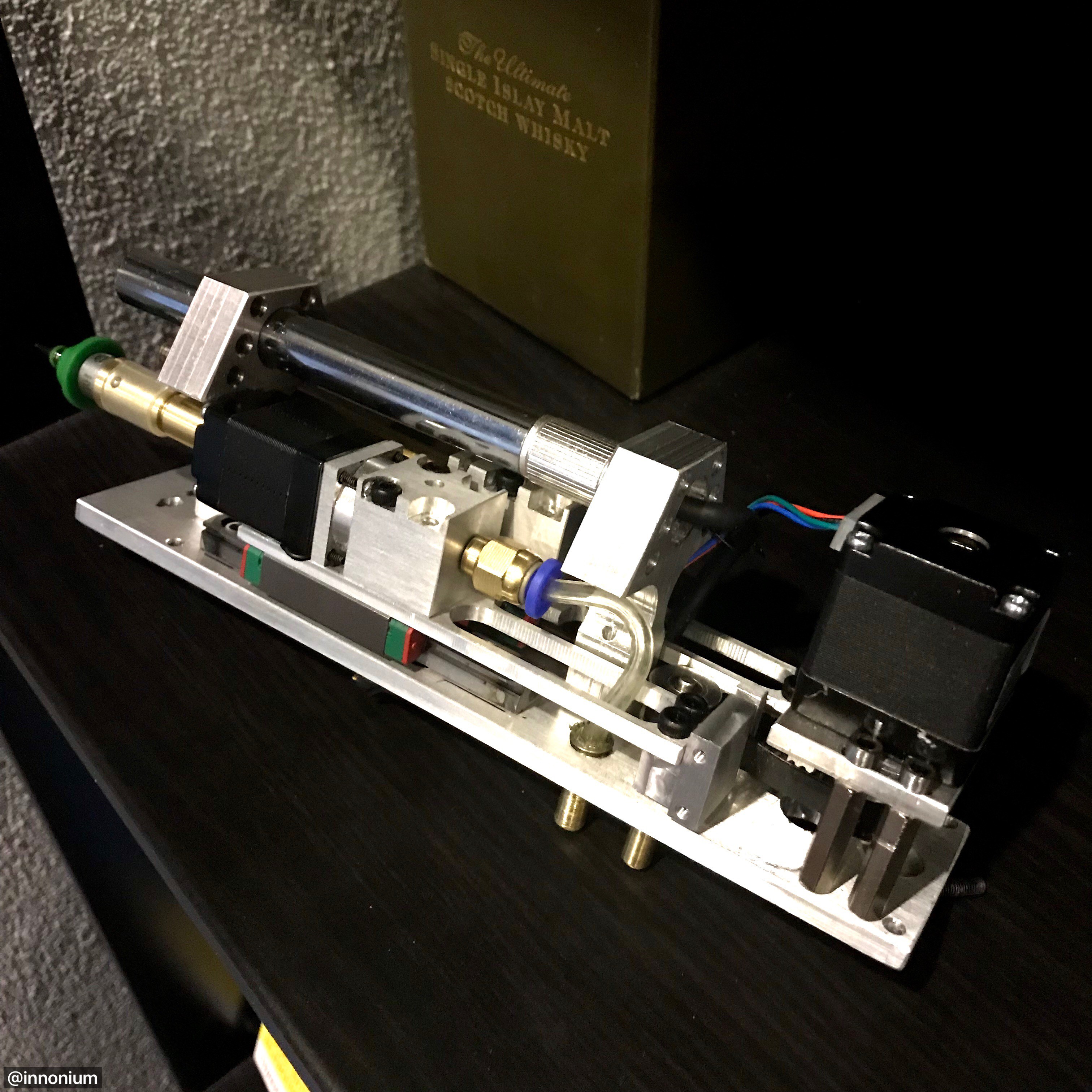

There is some initial development going on with paste&glue dispensing toolhead to name a one...

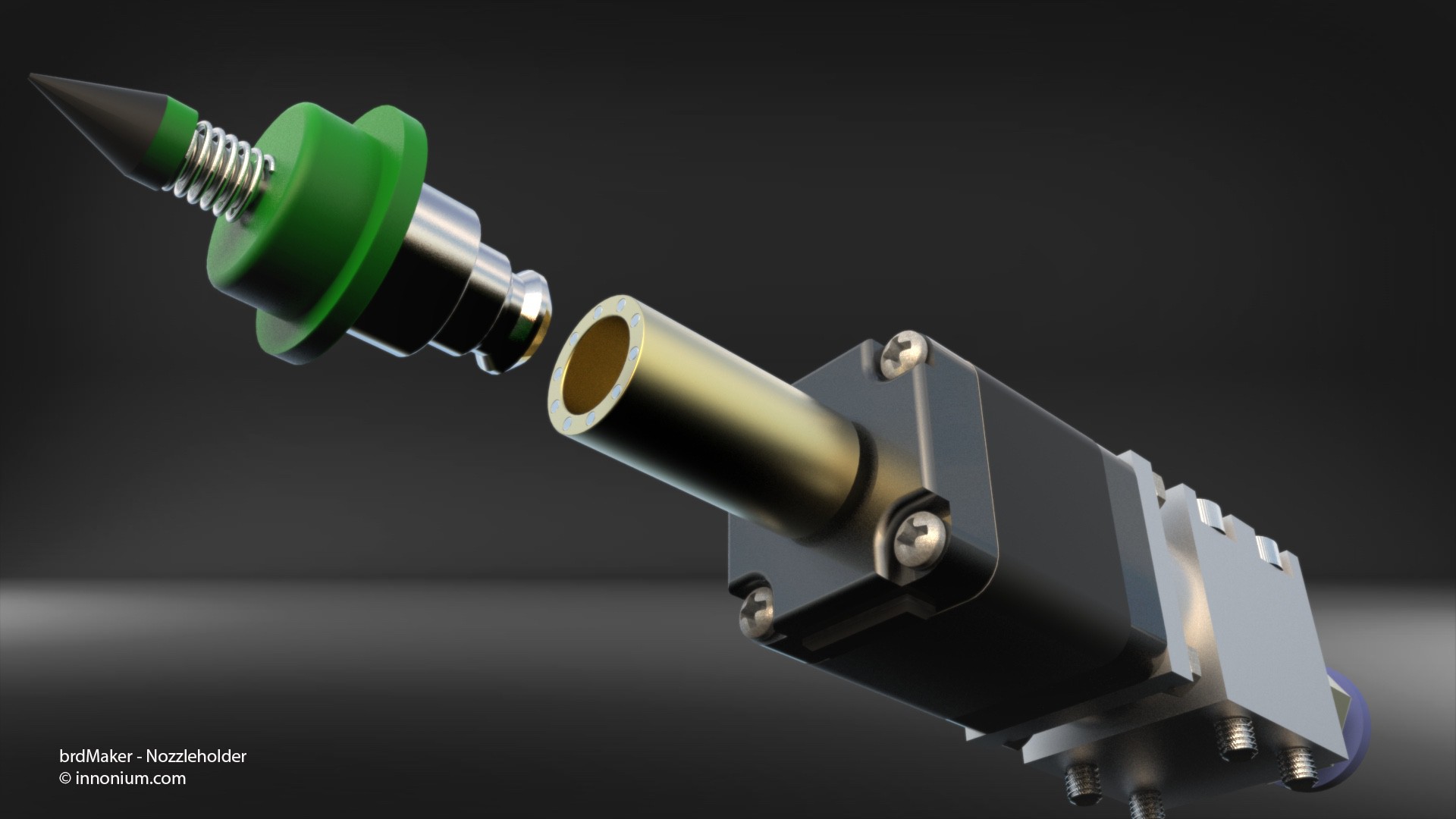

Own magnetic nozzleholder is designed to enable automatic nozzle changing with very low runout.

Feeders are organised into racks having backbones. Lot of software development done on the feeder management system.

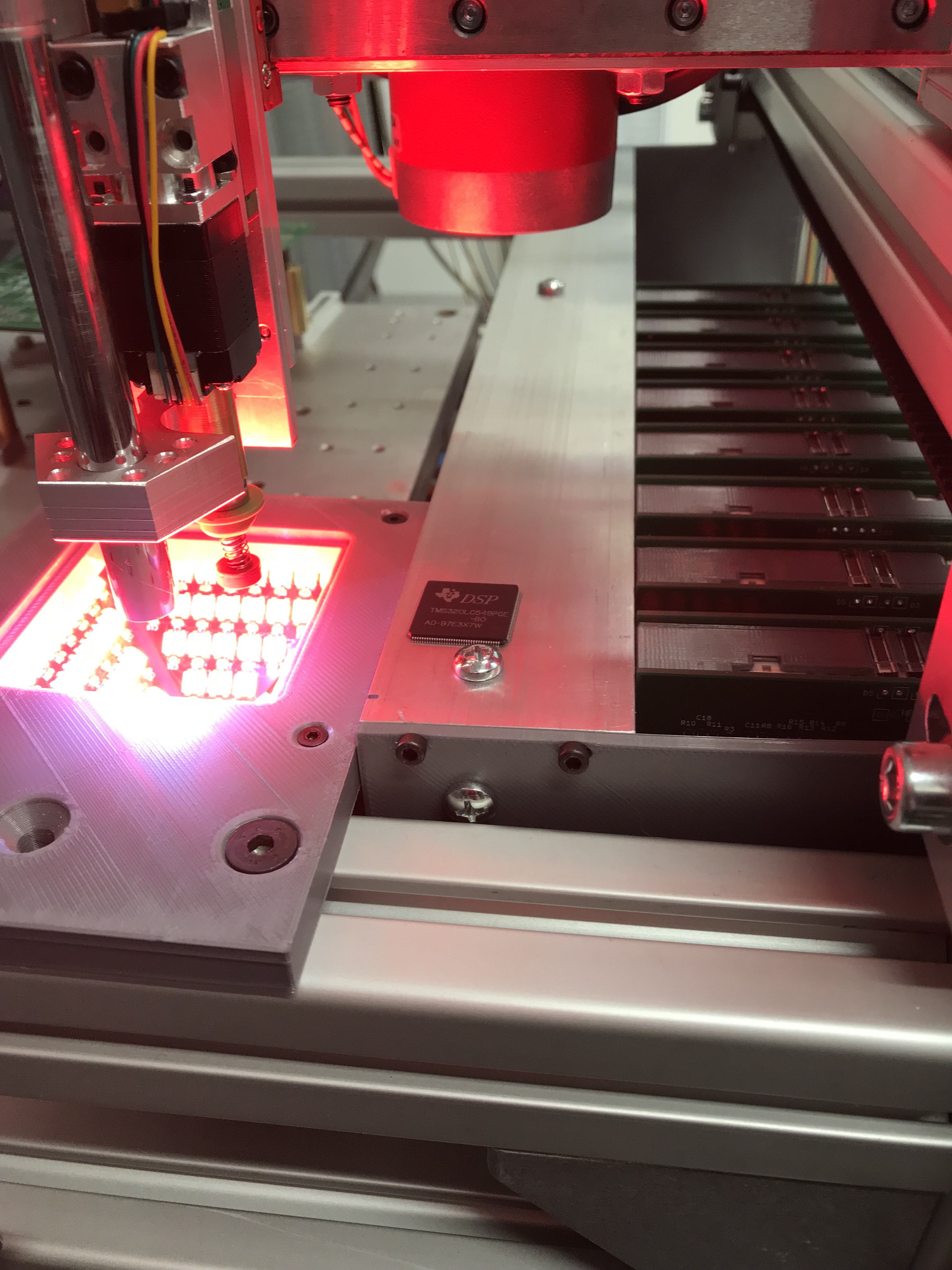

Custom bottom light system works nice.

Here some activity shots from our instagram account @innonium.

Mika Heikkinen

Mika Heikkinen

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.