Design Process thinking: One of our early prototypes included an extruder for 3D printers.

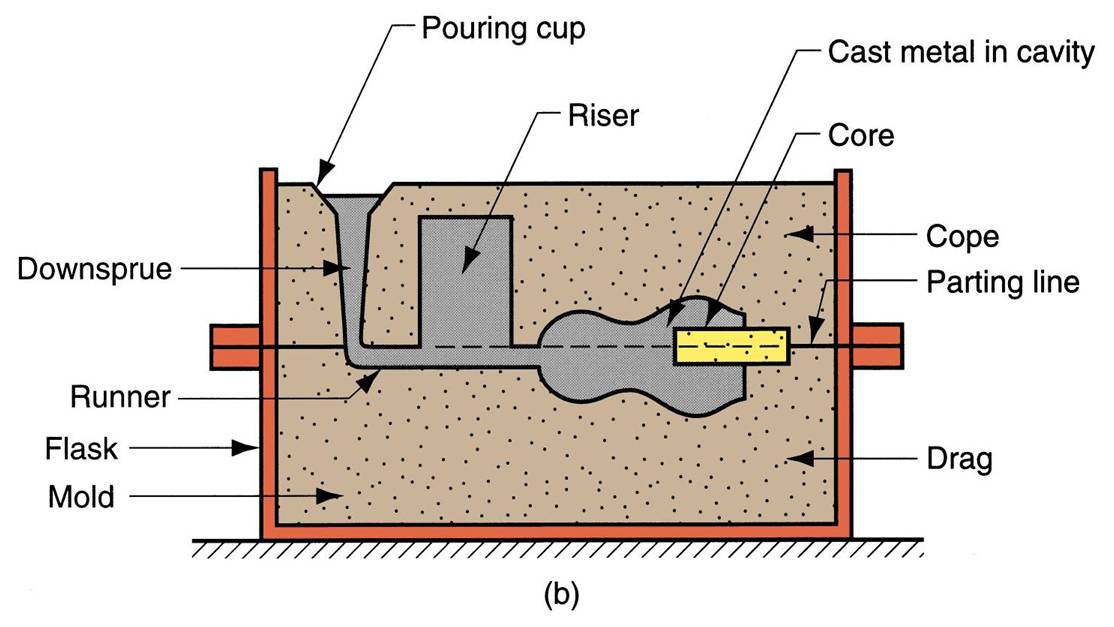

After 3D printing the part, we can now begin the mold. The process of creating the mold requires planning and some new vocabulary. Gates allow the material to enter the cavity. Runners are passages that distribute the liquid metal to the different areas inside the mold. Risers are reservoirs of molten material. They feed the material to sections of the mold to compensate for the shrinkage as the casting solidifies.

Molding process: Plan the gates / runners. Attach runners to gates then the gates to object. Above is a completed mold, there will be another picture showing a cross section and making of the mold. Right now the 3D printed parts are coming out a bit off so the printer needs to be recalibrated for newer test pieces.

Julia Longtin

Julia Longtin

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.