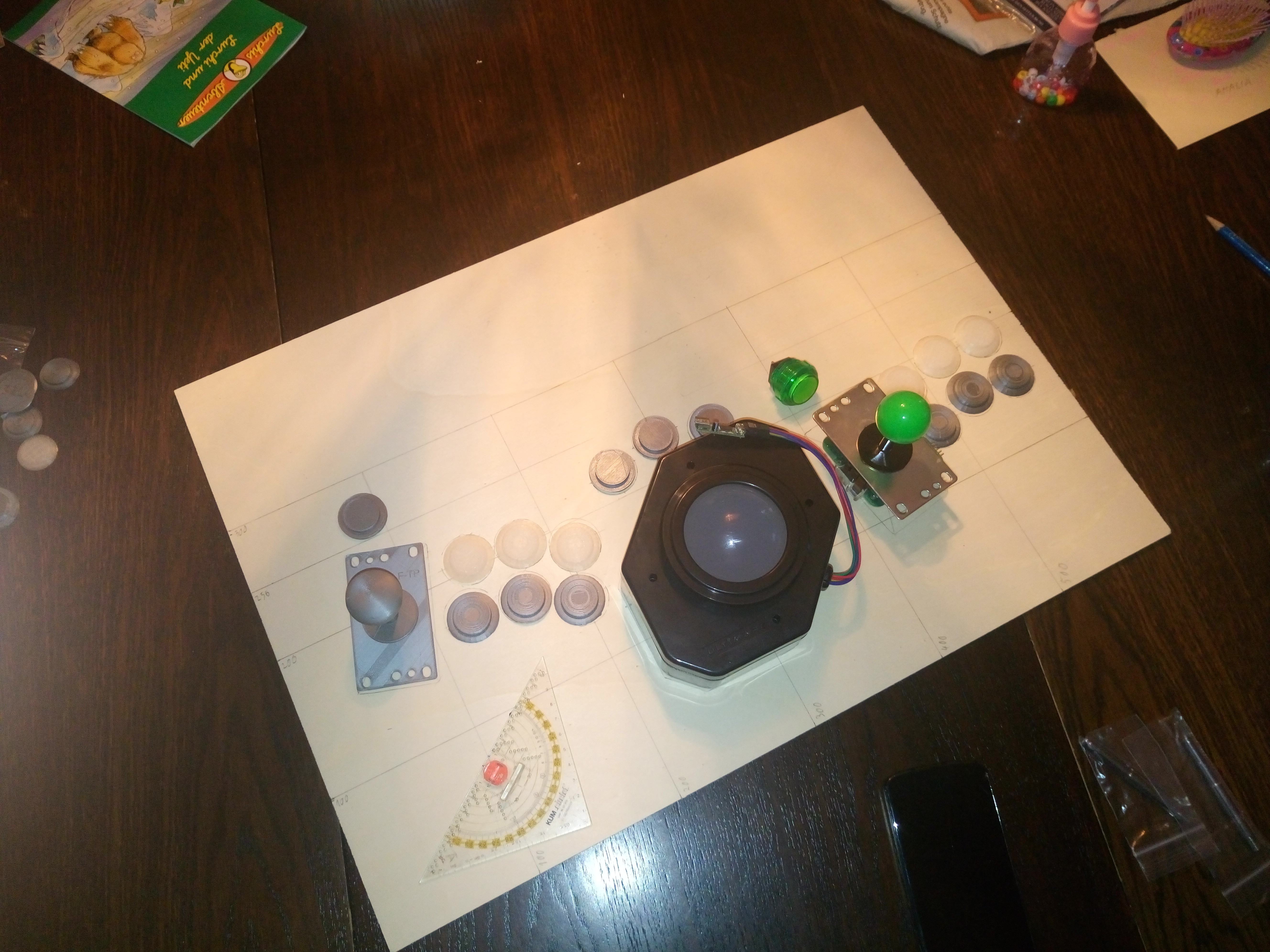

A few hours of printing later I had actual, tangible parts of all my control elements. I designed the models in a way that the controls hat a 1mm "bounding box" of their footprint under then panel, so that it was not possible to move the parts into a position that might be comfortable but unfeasable.

I grabbed a plywood sheet, cut it to the indended width of the machine, placed it under the Monitor and started to move my controls to a desired position.

It tunred out that I underestimated how much space I would need for my hands to lay comfortably on the panel. In my originals drawings everything was too close to the edge. Furthermore, I noticed that this is even more so on the left side of the panel, as the hand on the buttons Needs more resting-space than the hand on the stick.

After all was figured out I placed the orders for all the parts and played the waiting game.

After measuring the exact positions of my mock-up controls I transferred everything back to the digital model and transferred the center points of each hole to the prototype plywood board.

Time to cut and drill!

treibair

treibair

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.