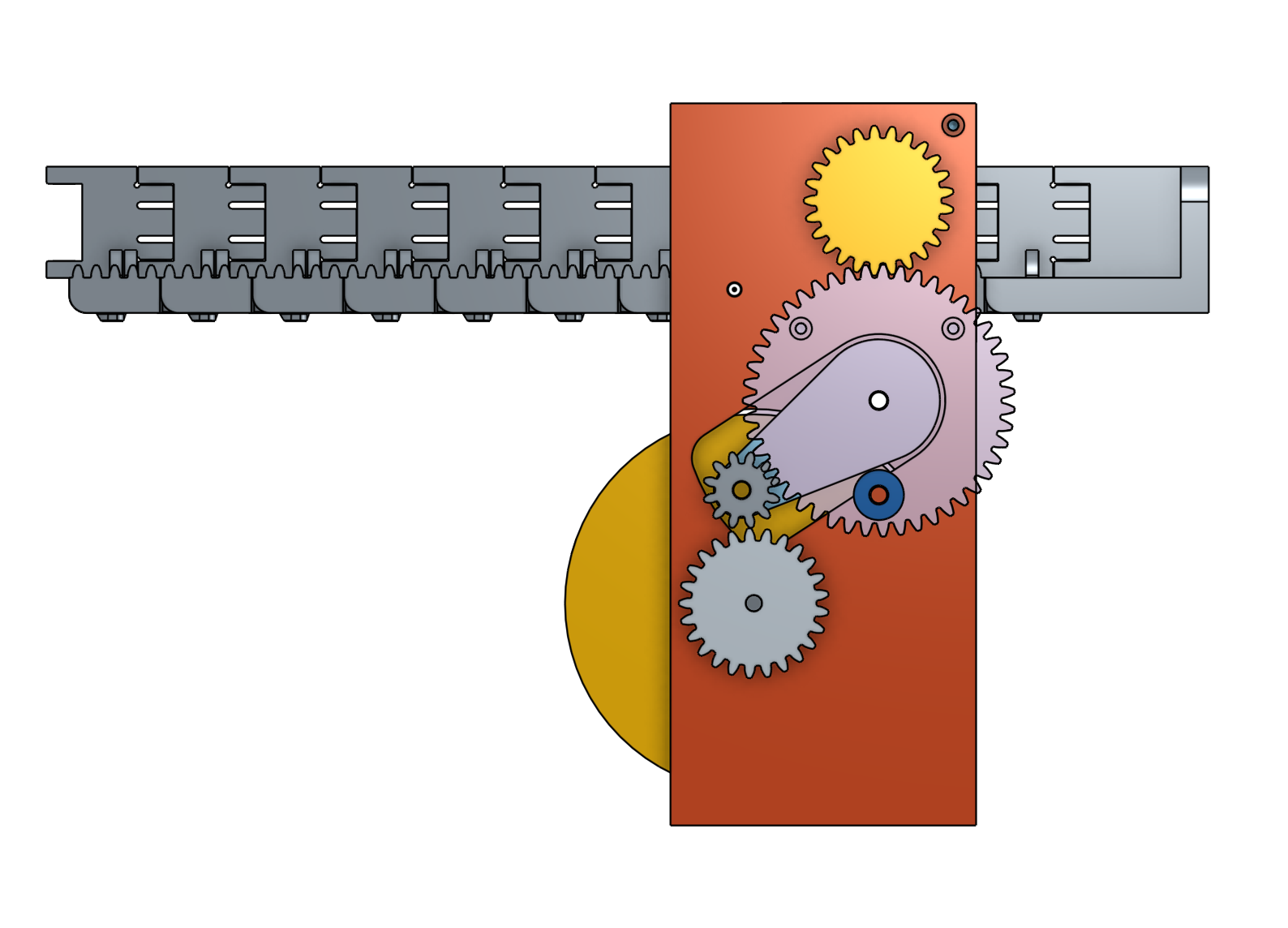

Reeling the chains in or out has been challenging. It has proven difficult to get the rate at which the beam is interlock/extruded and the rolling to match. I tried first with a design for an active rolling on retrieval, but passive on extrusion based on a smal gear on a floating lever. The gear only engaged when the gear train was driven in one direction.

In practice once the roll got a certain amount of turns, it was not possible to be "rolled" out just by the extruder pulling on the chain.

So it was back to the drawing board =(

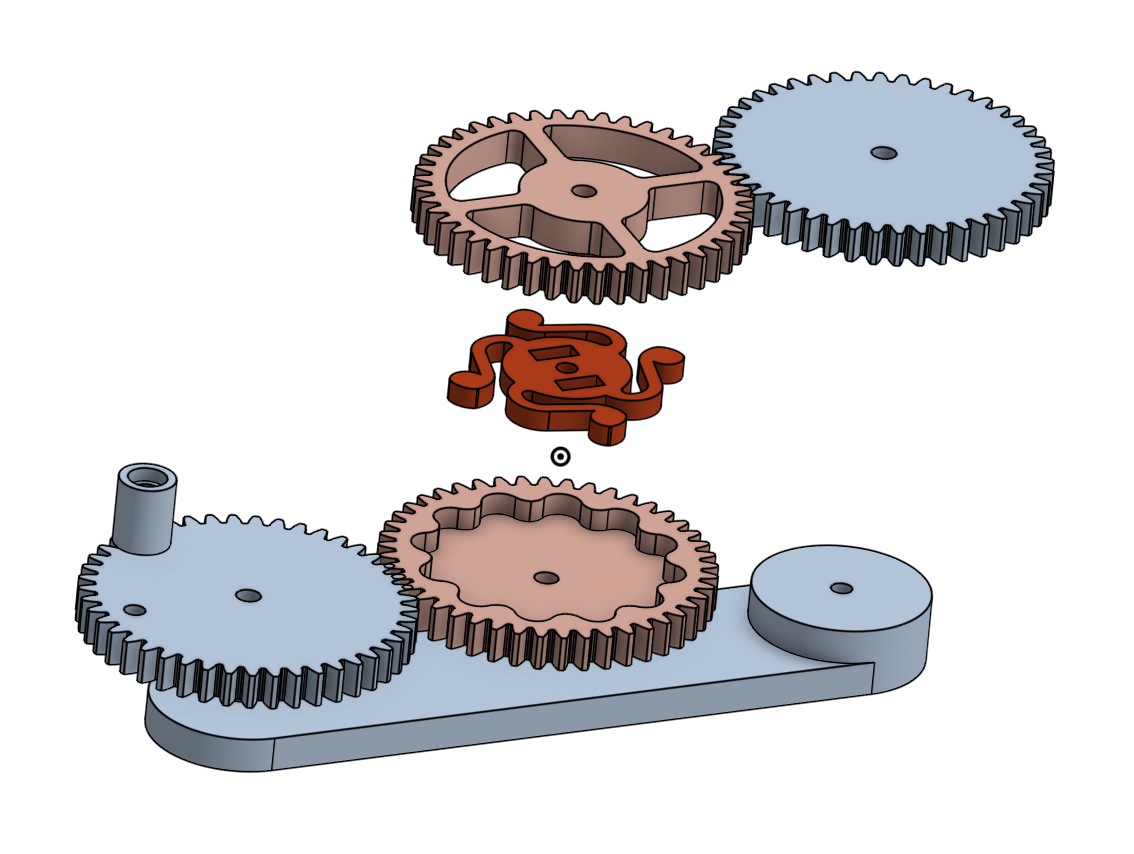

What I needed was a gear with a "safety-ratchet". Instead og jamming I wanted the reel to skip if it was too slow or too fast in relation to the extrusion. This is what I come up with:

On this "safety-ratched gear" he amount of "give" or "grip" can be configured by changing the dimensions on the central spring. I did a number of prints to test the different sizes/geometries until I found one with the right resistance.

I have uploaded the test rig to Pinshape if you want to play with it. You can get the STL there: https://pinshape.com/items/37022. You can edit the CAD to fit your needs using this link to the shared OnShape project: https://cad.onshape.com/documents/f6e...

Ronald Jaramillo

Ronald Jaramillo

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.