So the SLS nylon parts arrived from Shapeways and i've put together one actuator. unfortunatly the brass screw inserts which were supposed to be M1.2 turned out to be M1.5 so i managed to find x3 M1.5 screws in my bag of tiny screws from dismantled stuff. The others will have to wait another few weeks until the re-ordered inserts arrive, but at least i have one to run tests on, which I'm quite pleased about. More below the break....

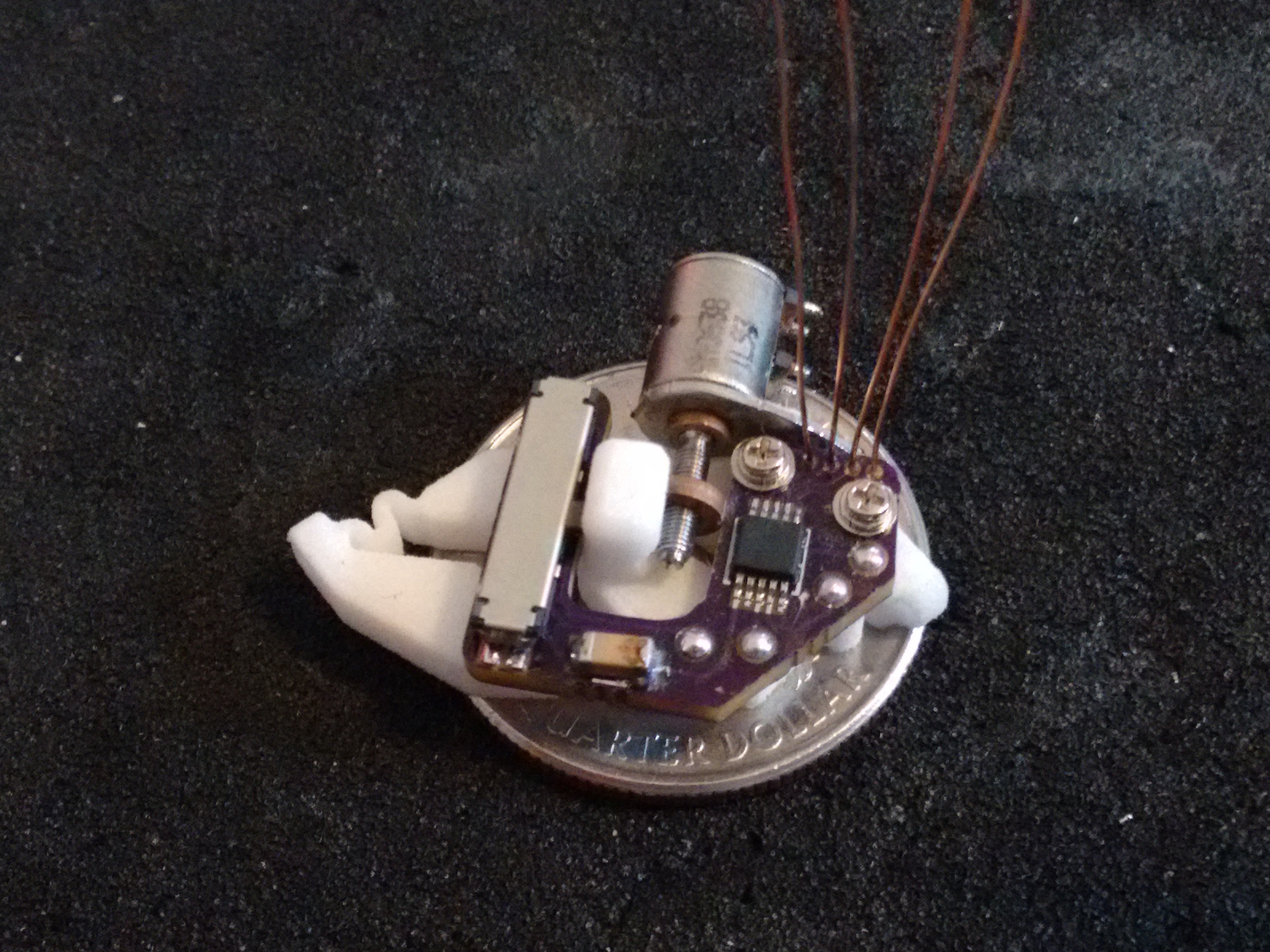

Actuator sitting on US quater (24mm diameter)

The grey and black parts are from the new HP fusion jet that Shapeways is trialing and the results are certanly sharper (the hinge sections are much closer/thinner to the design) than their standard 'strong and flexible' machine.

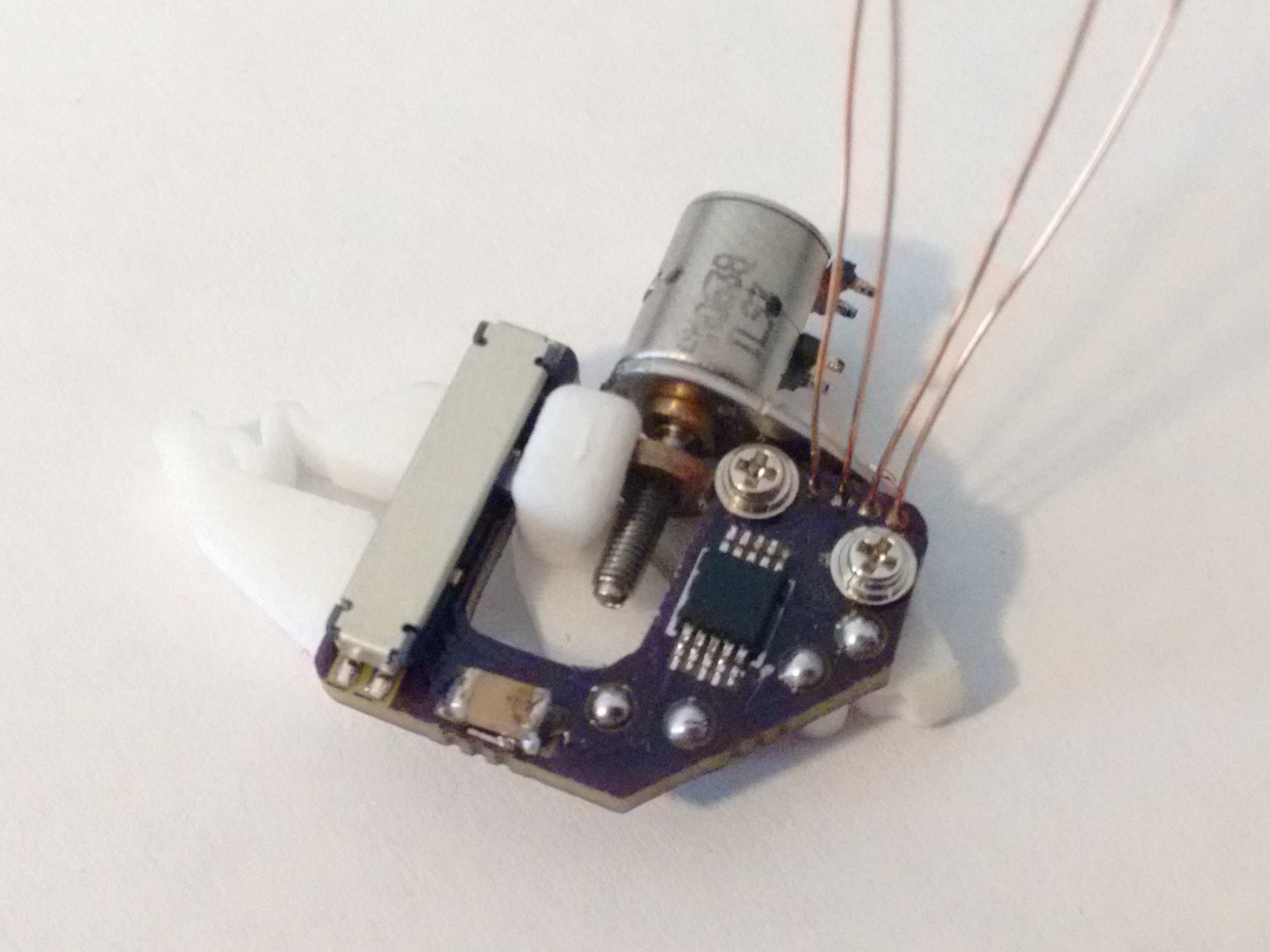

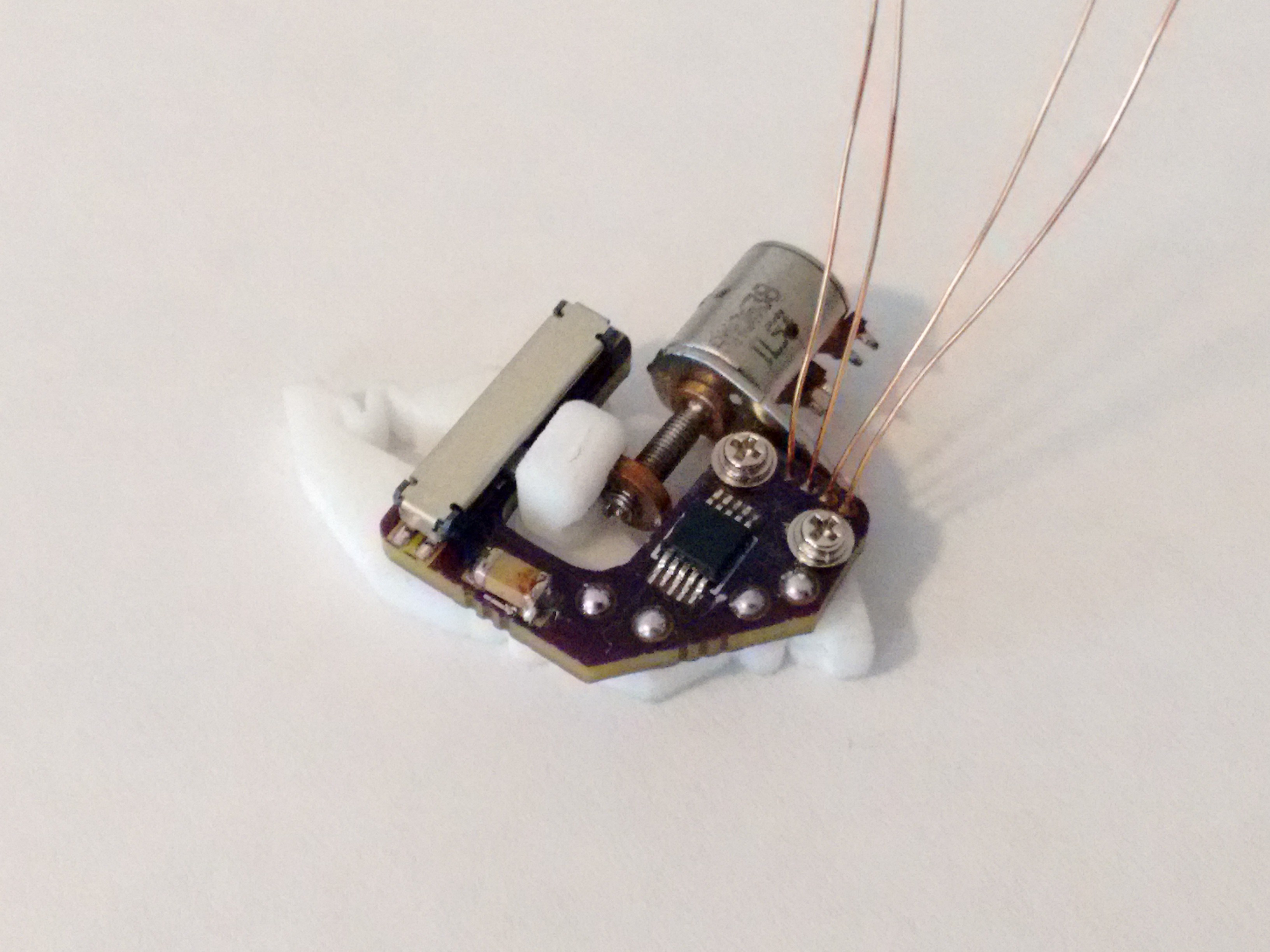

I've not yet had a chance to wire up the motor but using the slot in the end of the shaft I've been able to explore the response through most of the range in movement. So for approximatly 5mm nut movement (which is like squeezing the narrow points of a diamond/rhombus) the length of the actuator changes by roughly 1.24mm.

Full nut retract (actuator extension)

Full nut extension (actuator retraction)

David Brown

David Brown

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

Very exciting... and so small! :D

Are you sure? yes | no