So its been a while since I last posted, some of that was waiting on parts to arrive, such as the SLS printed nylon gears and lever arms. And some of it learning how to use a 3D printer and get it setup correctly, along with other sub-projects.

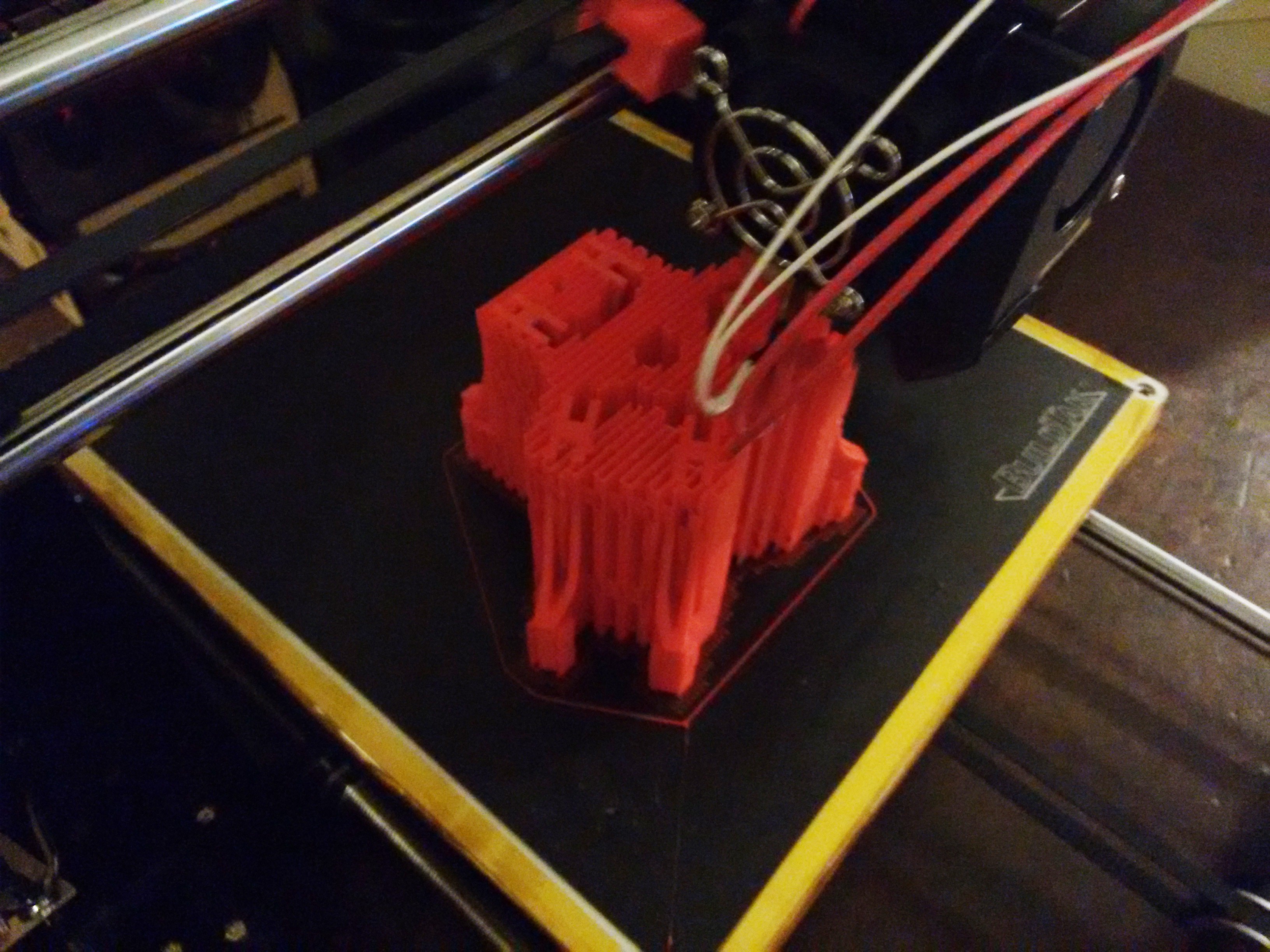

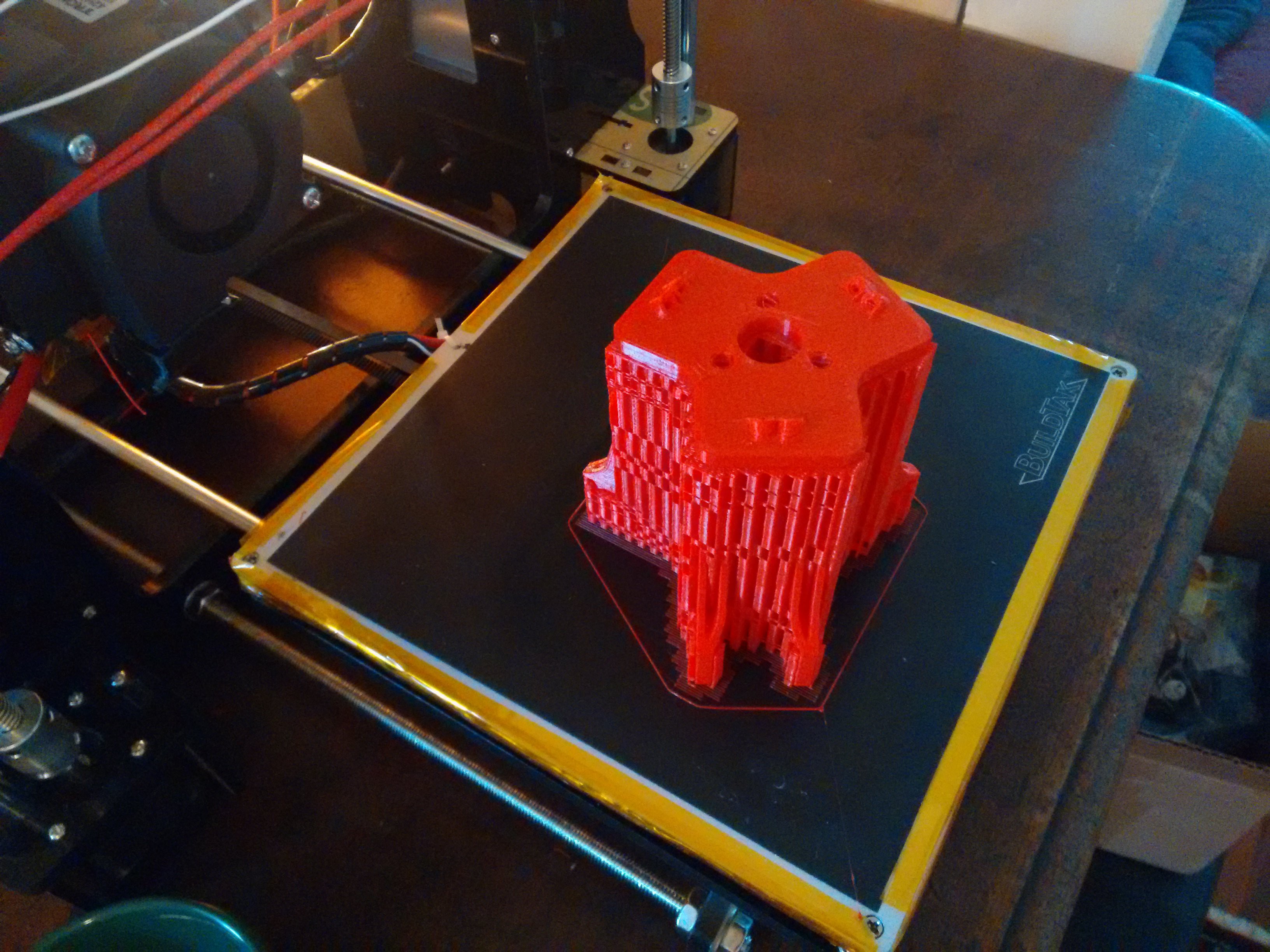

The print of the frame took 15 hours and i was pleased with the quality, given that this was using the $150 printer with all stock nozzle, etc. I'll post up the models for the parts shortly. More after break below;

The print of the frame took 15 hours and i was pleased with the quality, given that this was using the $150 printer with all stock nozzle, etc. I'll post up the models for the parts shortly. More after break below;

By using the printer the cost was probably $5 of filament and 15hrs of time, versus $68 if i had used shapeways. So the printer will pay for itself in short order.

By using the printer the cost was probably $5 of filament and 15hrs of time, versus $68 if i had used shapeways. So the printer will pay for itself in short order.

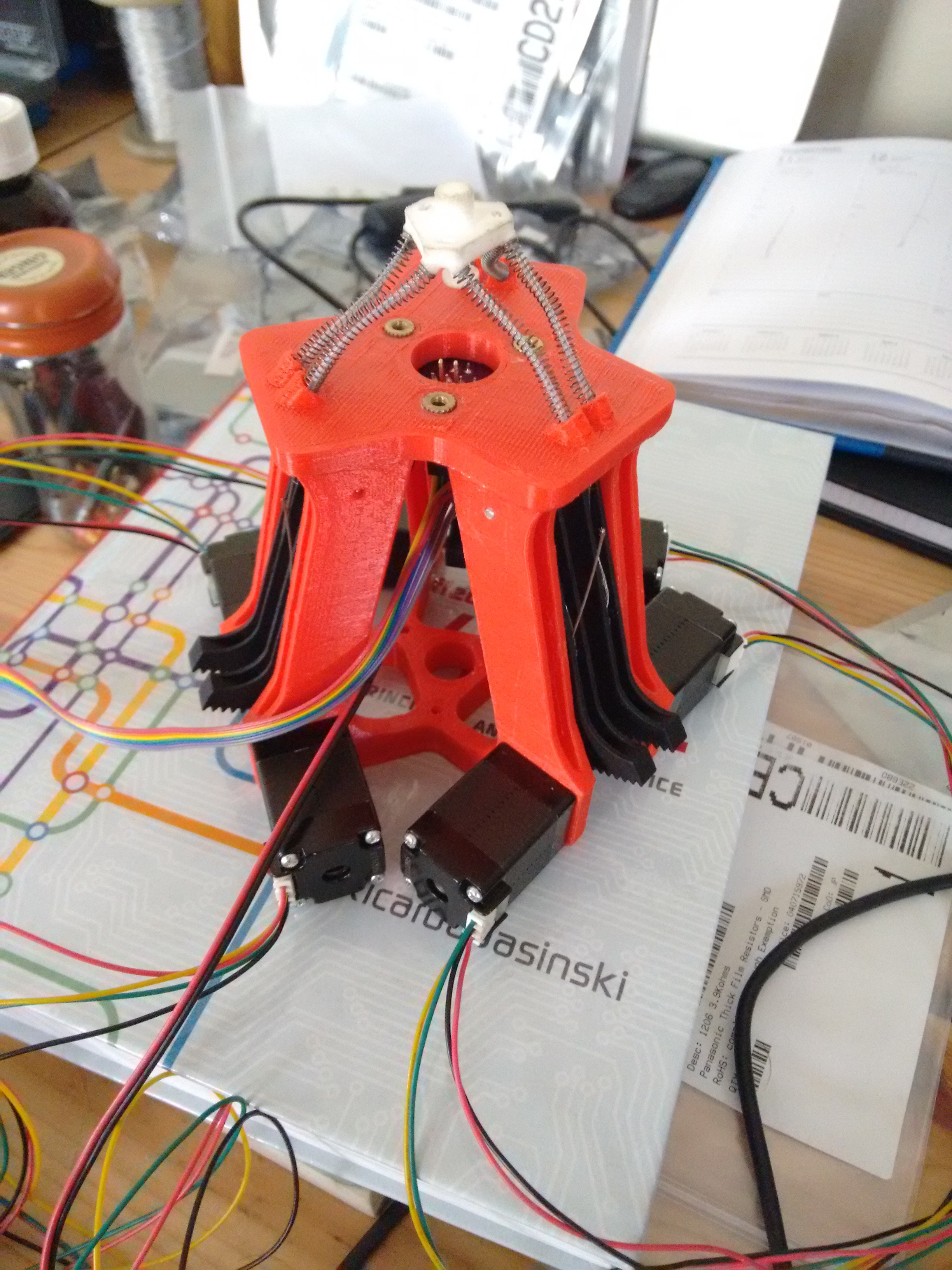

I used shapeways for the motor gears and lever arms as i needed the higher resolution to get a good resolution for the involute teeth. The lever arms are bushed with PTFE tube with 2mm ID (used as bowden tube for 1.75mm filament).

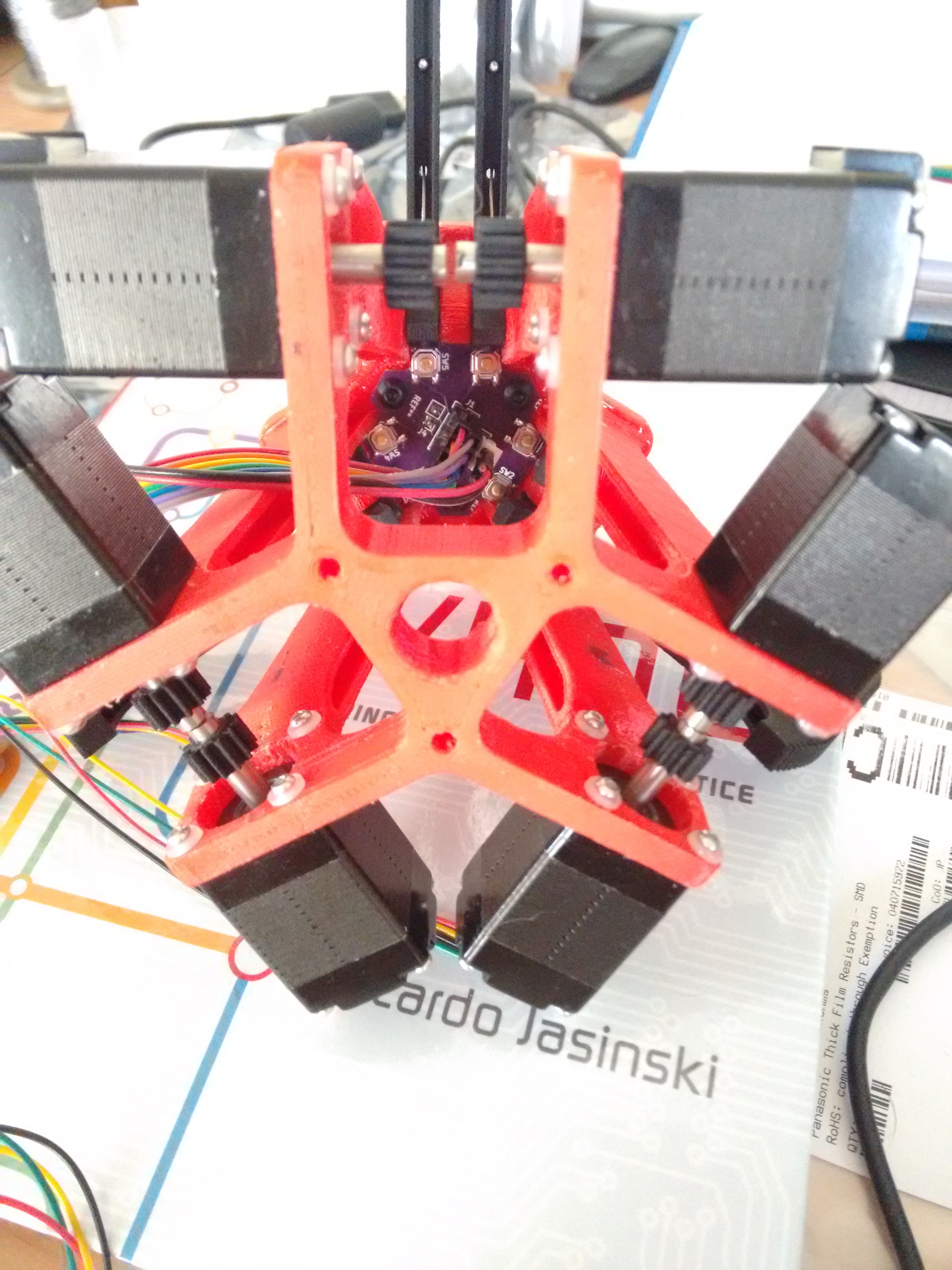

You can see the PCB in the base with the end stop switches that allow the lever arms to be set to a known position.

You can see the PCB in the base with the end stop switches that allow the lever arms to be set to a known position.

The platform end is also SLS printed nylon and I drilled out the doles for the wire cables using a 1mm drill bit.

The platform end is also SLS printed nylon and I drilled out the doles for the wire cables using a 1mm drill bit. So far I have put together code that takes the position requested and calculates the required leg lengths (sprung sections), and then moves the levers the appropriate distances. The code is likely not optimal, but should be readable and understandable, i've used atmel studio C++ AVR, but again it should be easy to port the key sections to arduino syntax.

David Brown

David Brown

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.