Making prototypes

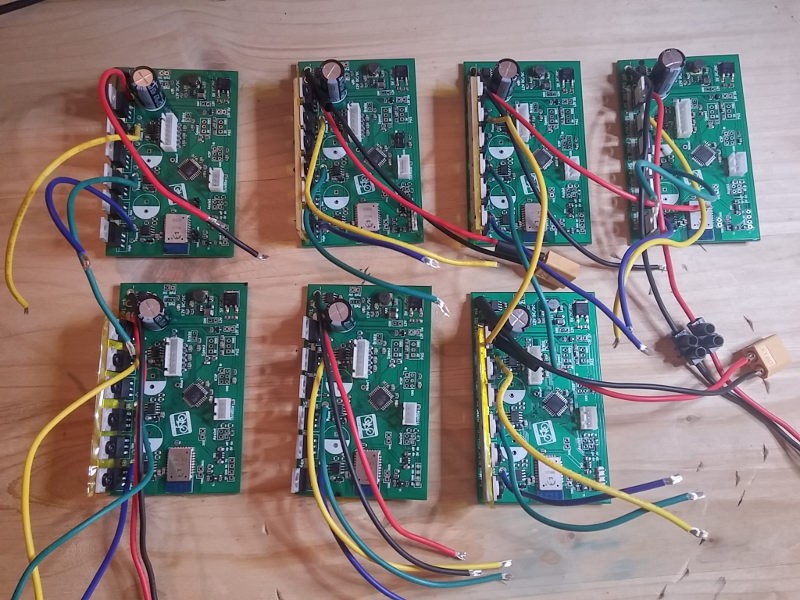

So far I have made a handful of prototypes for friends & family:

Doing them by hand is quite a lengthy process. The general workflow is

- applying solder paste to the PCB and placing the SMD components

- reflow soldering in oven

- first power up test slowly going from 0V-60V while checking that there are no shorts and all power converters are working correctly

- flashing the firmware and bootloader

- configuring the bluetooth LE

- soldering the THT components

- cutting the aluminium heat sink, drilling 6 holes and cutting the M3 threads

- applying the kapton tape and mounting the MOSFETs

- drilling a hole in the panel for the grommet

- mounting the whole board on a bike and doing a test ride

All in all it takes me well over three hours to make one controller by hand.

Currently I am looking into producing a batch with seeedstudio. The goal is to achieve a very competitive price tag of ~90$. This is about half the cost of what you currently have to pay for a cycle analyst and a controller while being a lot more powerful and lot less cabes.

Stay tuned for more updates....

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.