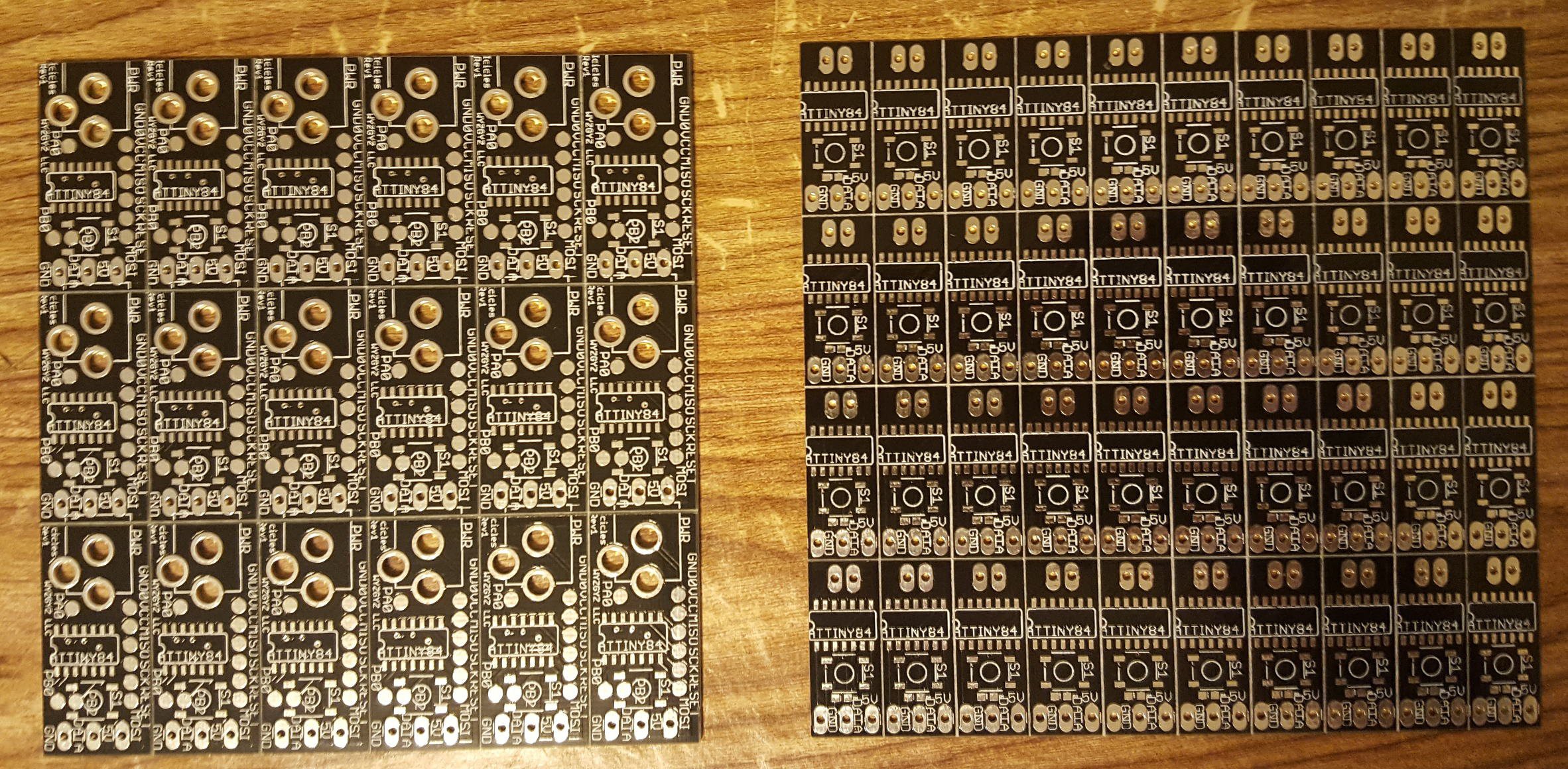

Figuring out the enclosure for the PCB was a disaster. I couldn't make it waterproof or find something easy that would work. Then I had a revelation. The LED strips are already coming in a waterproof silicone sleeve. Why not use that? I redesigned the PCB so that it was thinner (the same width as the LED strip), and tried again. When the new boards arrived, I populated a bunch and tried it out. Success! The new PCBs are smaller, so I can panelize more to a board. For $4.90 I can get 10 boards of 10x4, or 400 pcbs! The previous board was 6x3, so 180 for $4.90. I just halved my PCB cost and eliminated the need for a separate enclosure, and reduced PCBA cost because it's more dense!

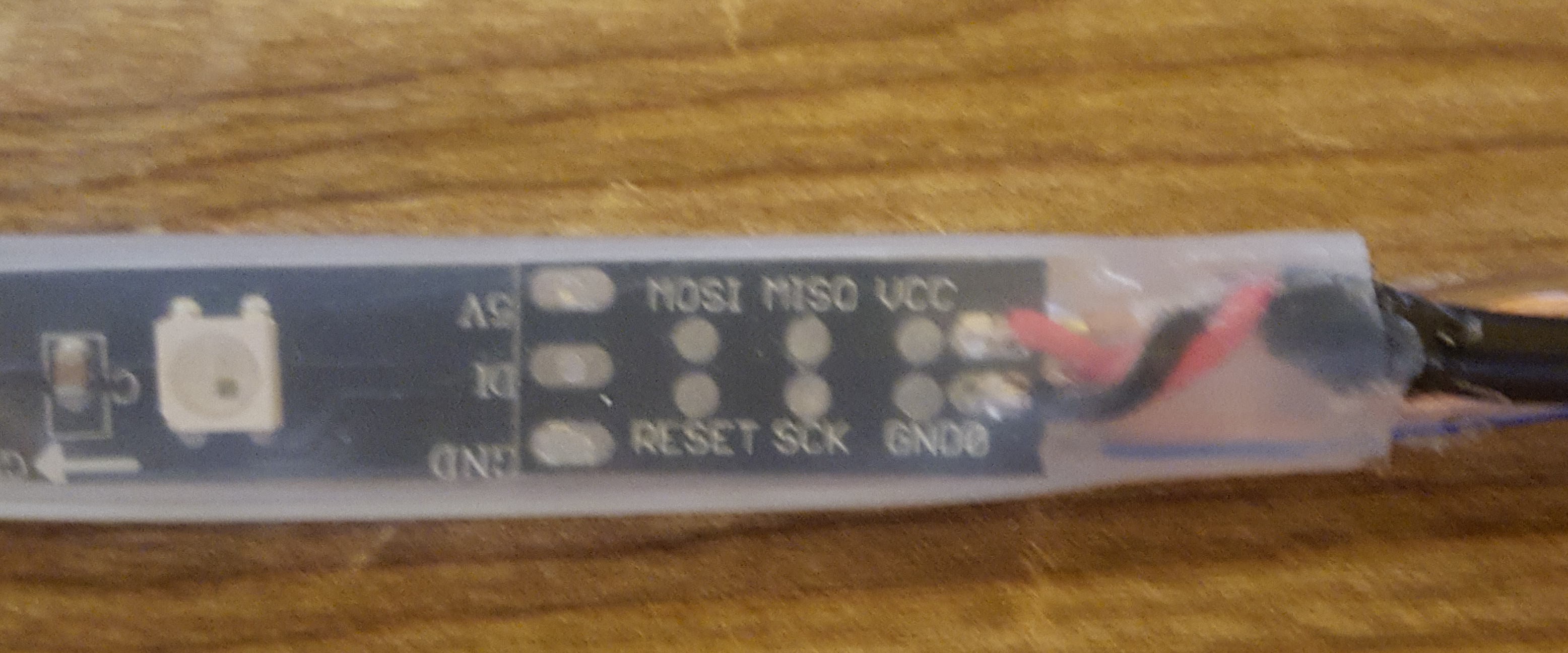

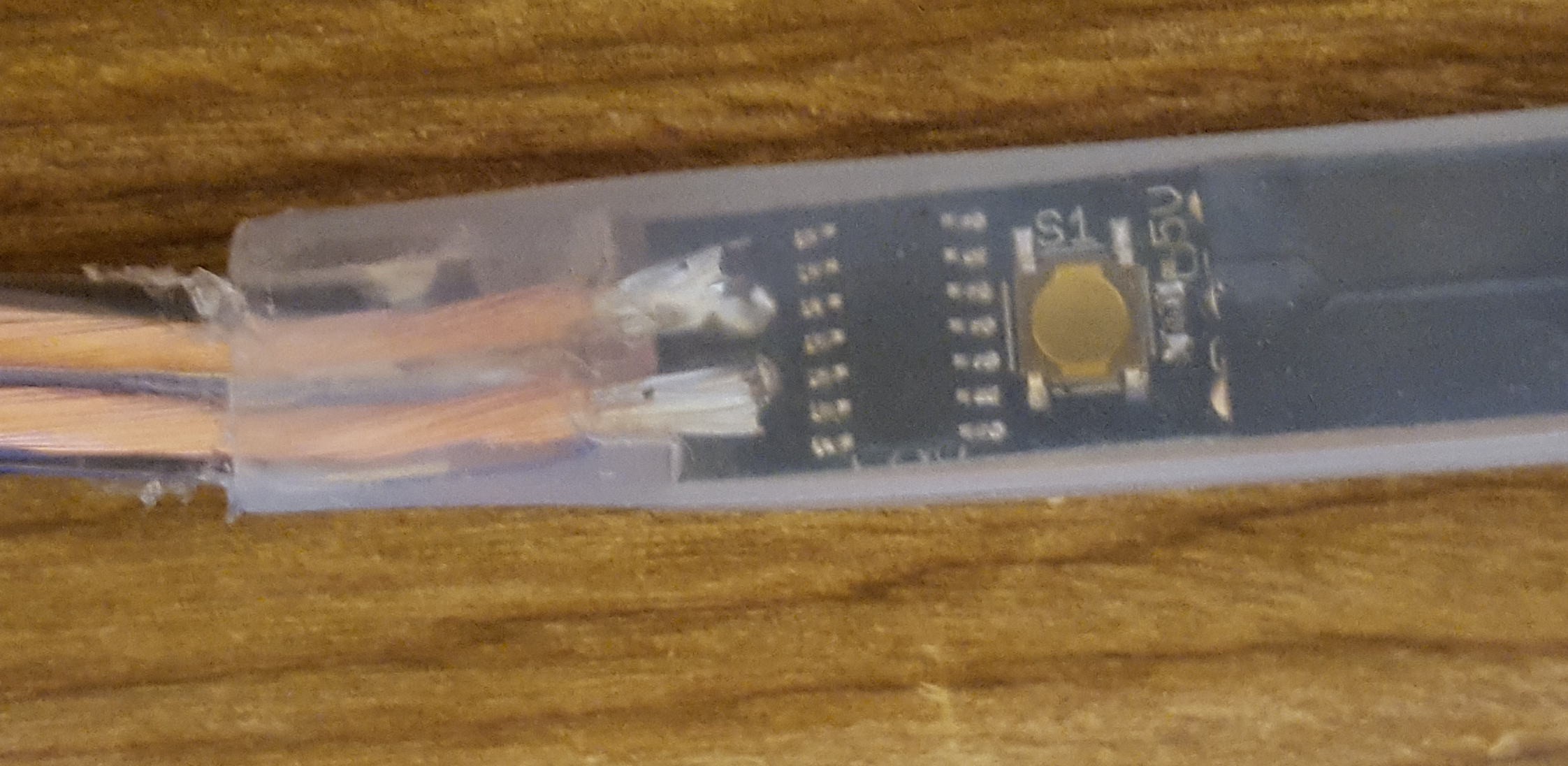

After assembly, here's what they look like slid into the silicone sleeve.

You may be asking yourself why the LED strip is upside down in its connection to the PCB. I don't really have a well-thought-out reason for this. The strips came with the 5V and GND in different places than I expected. It makes absolutely no difference, though.

Bob Baddeley

Bob Baddeley

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.