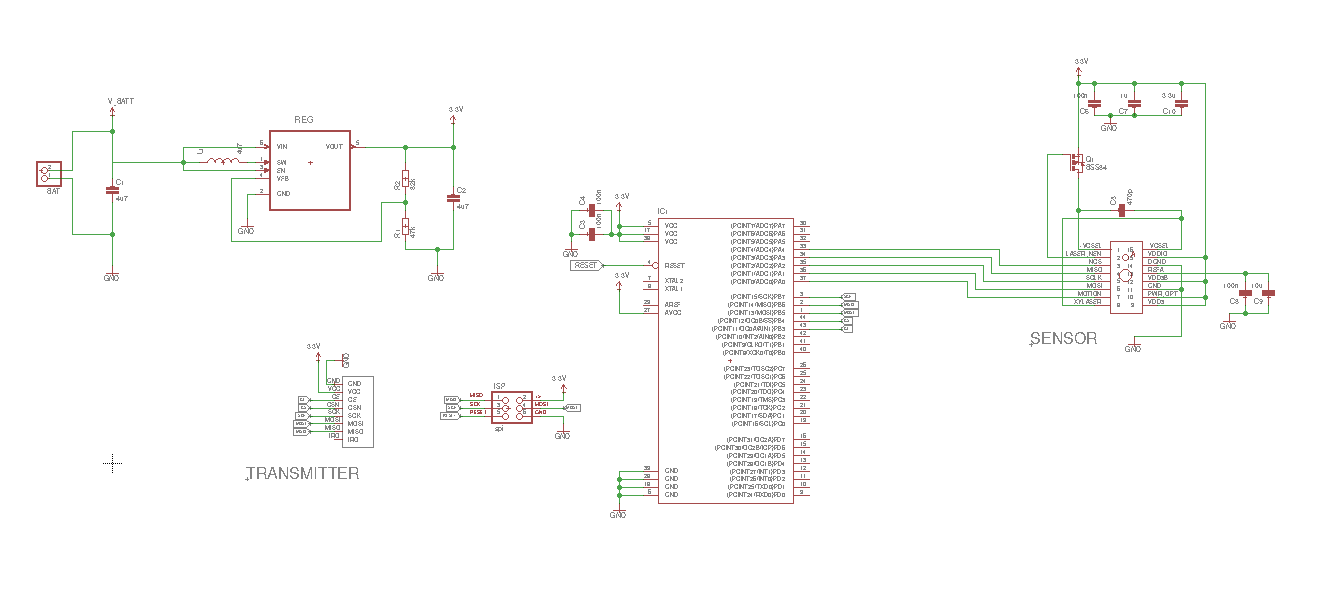

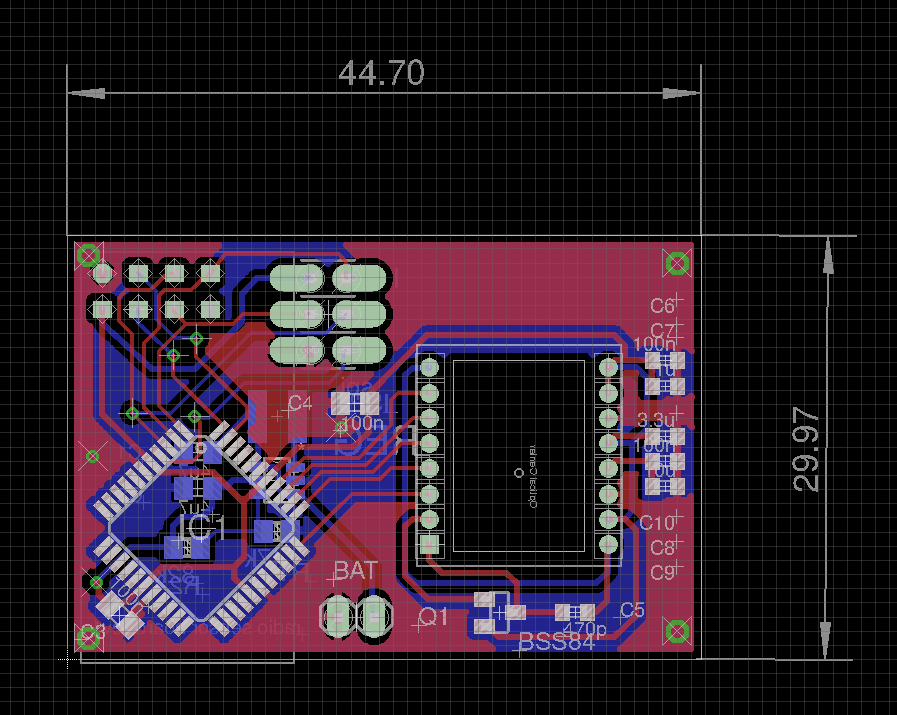

Sensor board

Sensor board is pretty straight-forward. It gets data from A9800, performs moving-average smoothing and sends it through NRF24. It is powered by single AAA battery with mean current draw of around 100mA which makes it usable for few hours of continuous work. It has to be mounted near sewing machine head around 2mm above the cloth surface.

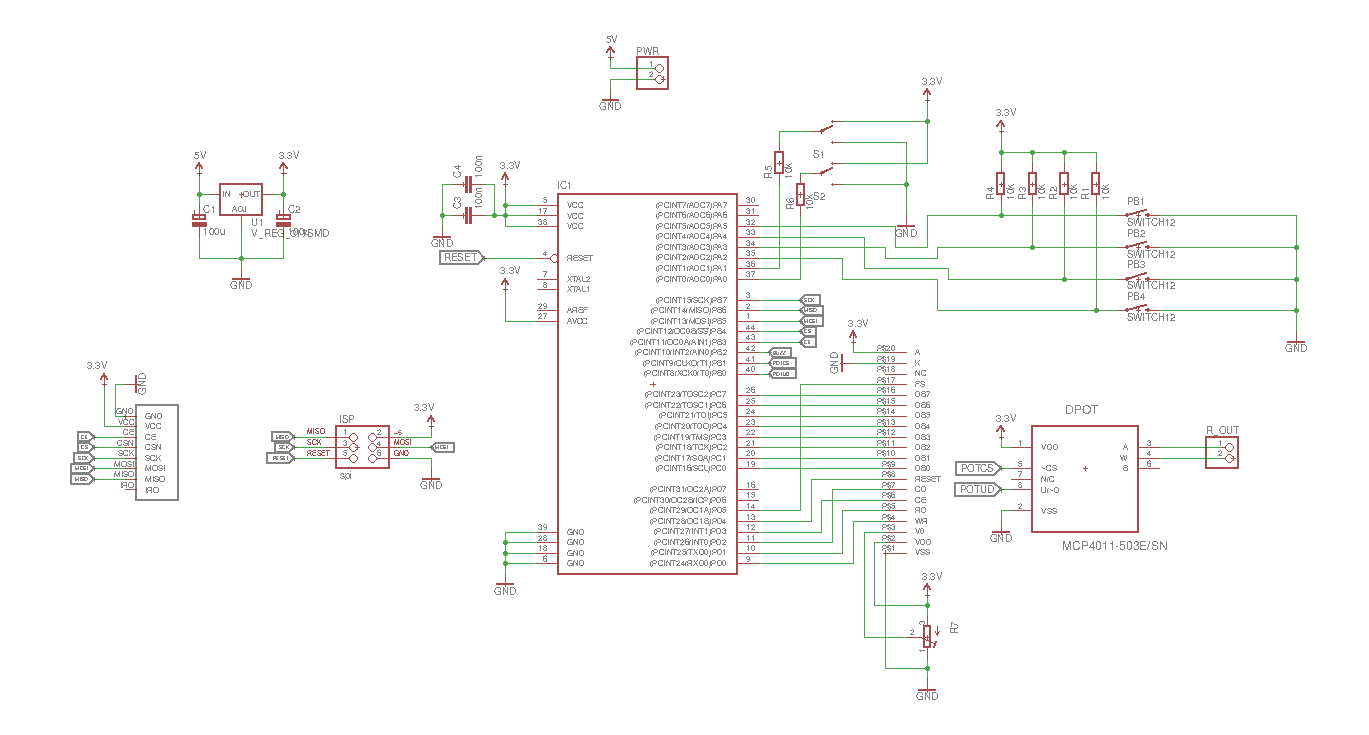

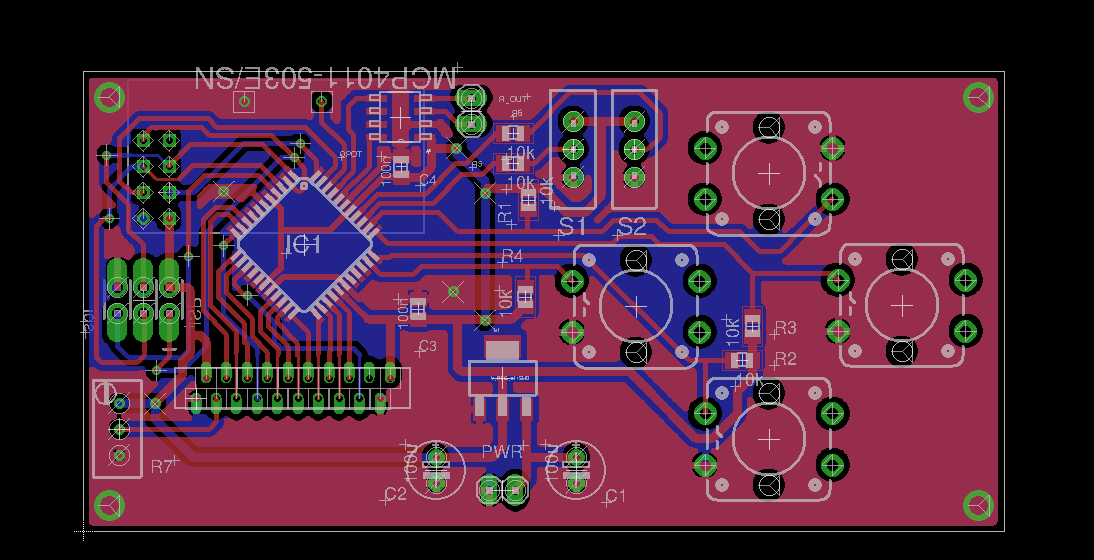

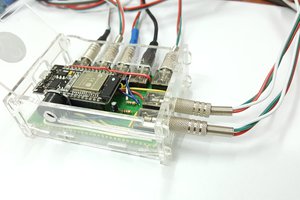

Display board

Display board is little bit more complicated. First of all it gathers data from sensor board (through NRF24), performs additional configurable smoothing and thresholding and then it sets value of programmable potentiometer. Resistance is then feed to sewing machine by jack port that normally is connected to analog speed pedal. Everything is configurable through simple gui which displays current readouts (I have used Nokia display here). There is one switch (SW2) which completely disabled potentiometer. SW1 contains additional element not displayed on diagram (10k resistor between +3.3V and its middle pin) which acts as voltage divider. SW1 middle pin is then connected to ground through jack connector where you can plug analog pedal to control sewing action (potentiometer output is enabled when pedal is pressed so user can easily maneuver cloth at low "idle" speed).

Display board is little bit more complicated. First of all it gathers data from sensor board (through NRF24), performs additional configurable smoothing and thresholding and then it sets value of programmable potentiometer. Resistance is then feed to sewing machine by jack port that normally is connected to analog speed pedal. Everything is configurable through simple gui which displays current readouts (I have used Nokia display here). There is one switch (SW2) which completely disabled potentiometer. SW1 contains additional element not displayed on diagram (10k resistor between +3.3V and its middle pin) which acts as voltage divider. SW1 middle pin is then connected to ground through jack connector where you can plug analog pedal to control sewing action (potentiometer output is enabled when pedal is pressed so user can easily maneuver cloth at low "idle" speed).

Maciej Żuk

Maciej Żuk

Rory

Rory

Khairey Nouhe

Khairey Nouhe

Abid Jamal

Abid Jamal

M.daSilva

M.daSilva

Hi. I'm interested in building your project. Ìs it possible to get all the information required to build it.