I can report success! To my big surprise, this works! And it works really well!

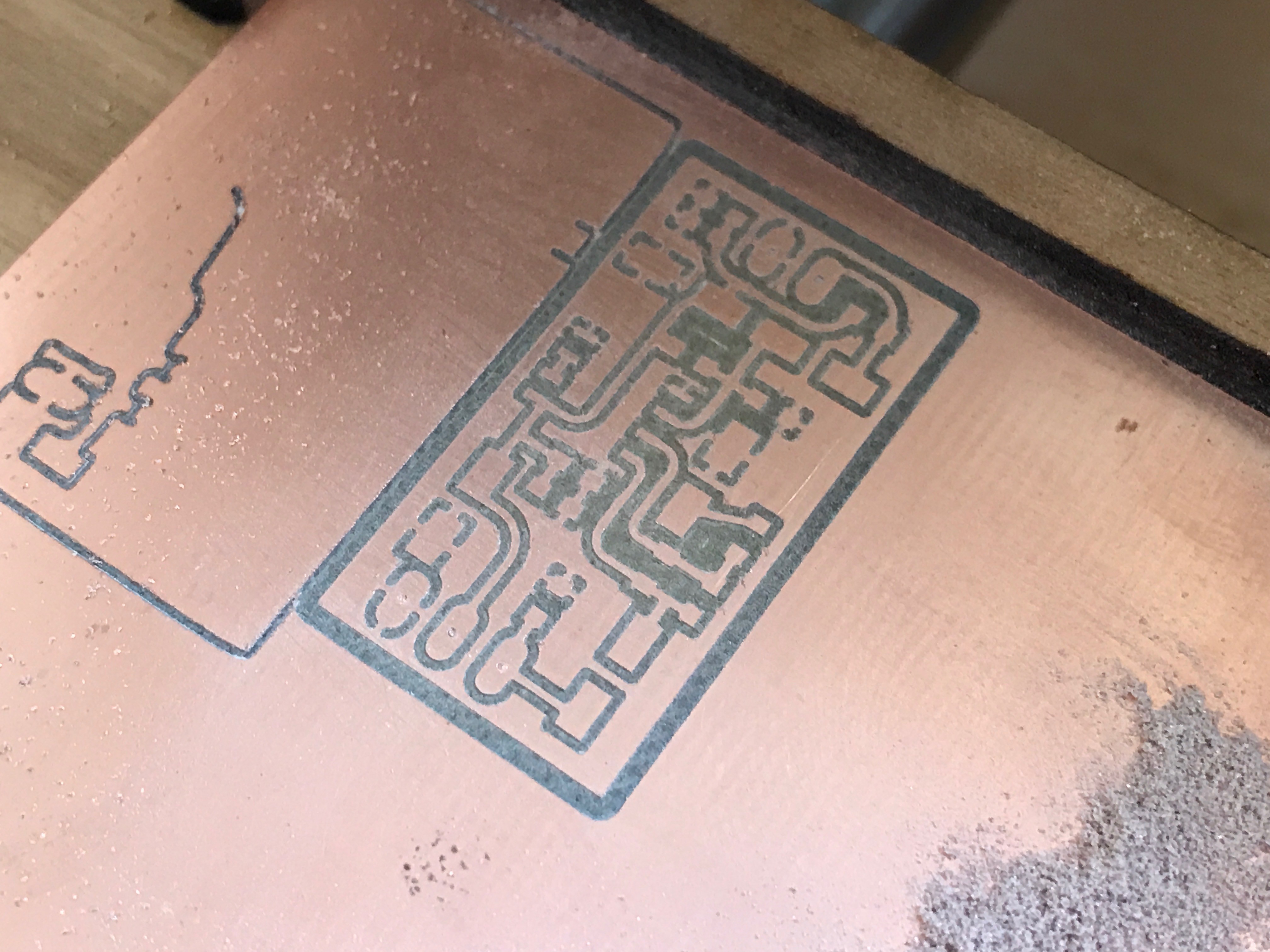

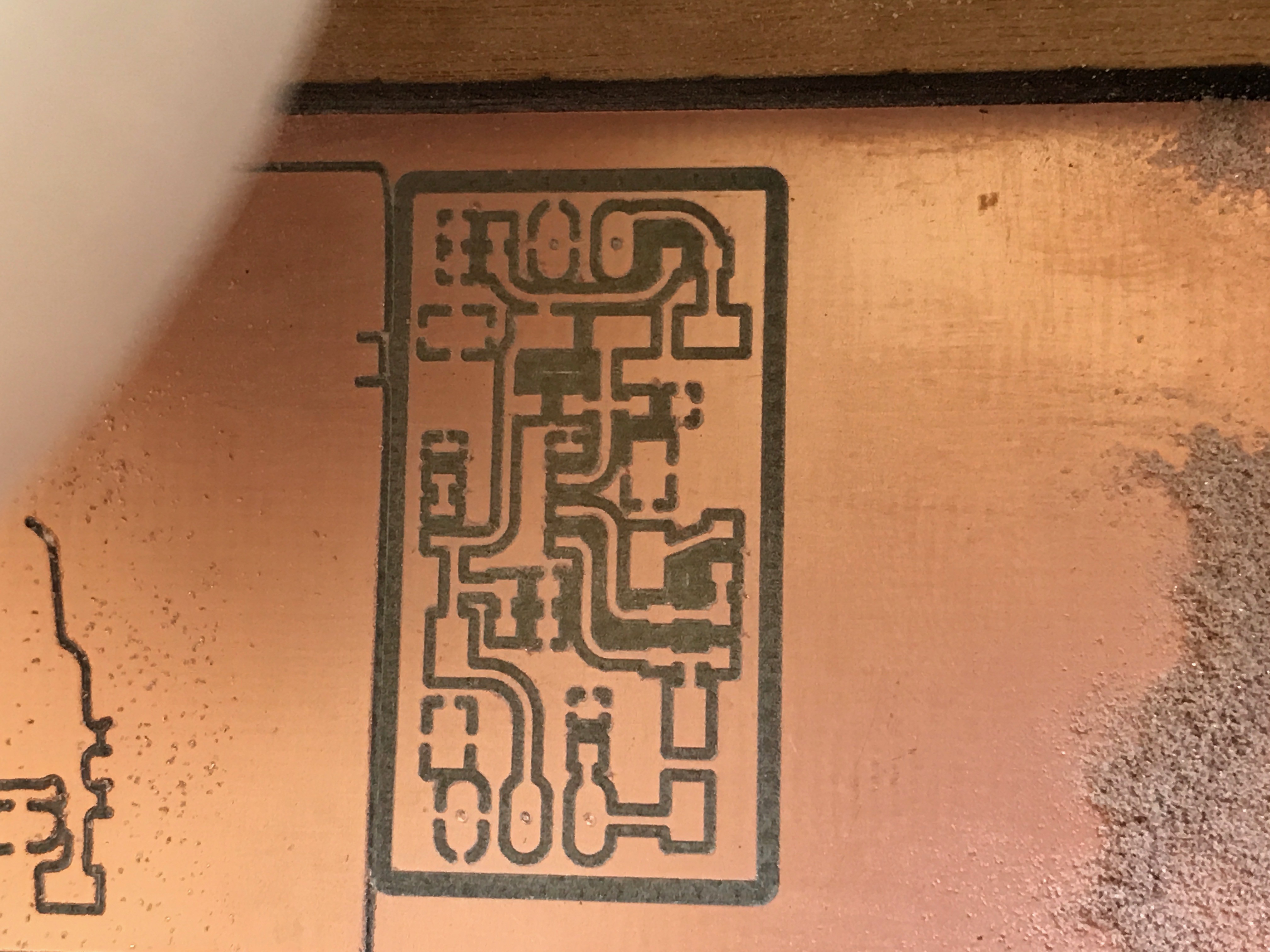

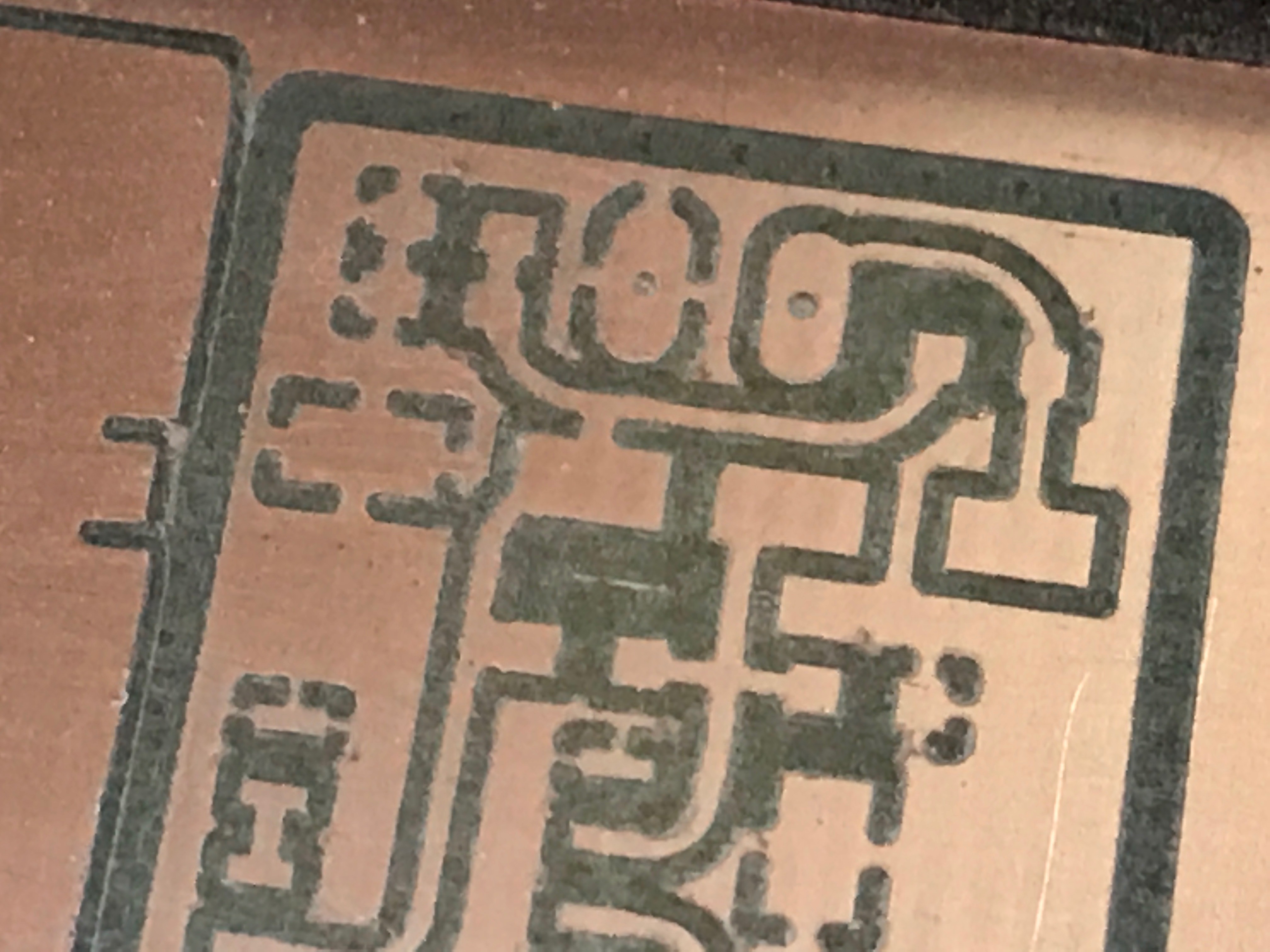

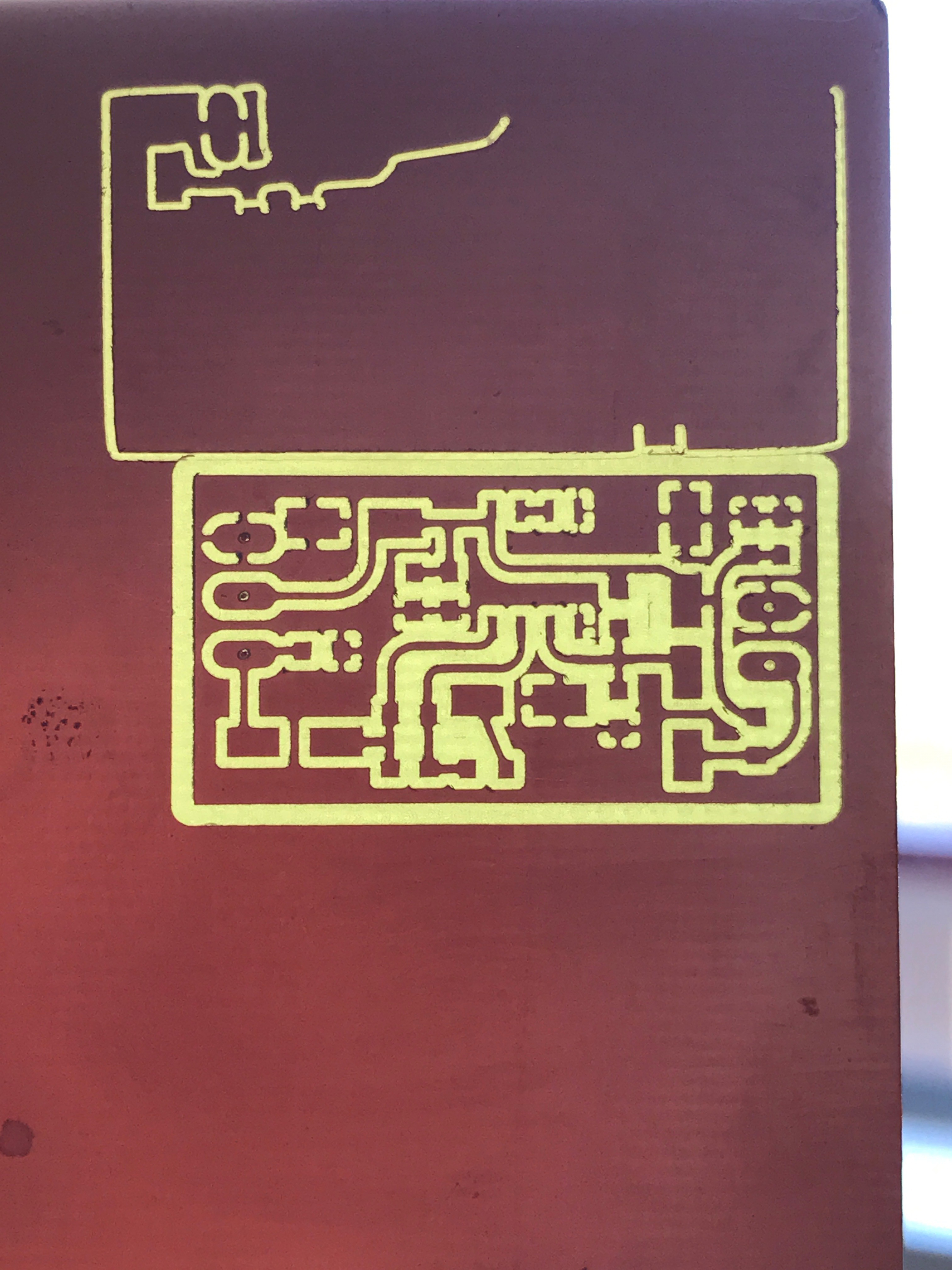

I ran one of my past projects on the mill just a moment ago. It is a microphone pre-amplifier that I used for my YouTube channel.

I can now autolevel the Z-height by using the actual mill bit and a crocodile clamp as a probe. That works really well. I will also try and use the CNC-gCode-Controller bed leveling function to probe the entire PCB to adjust automatically for unevenness of my board and mill bed.

For $200 this is a really good result. Much better than the results on my 3D printer and quite a bit better than on version 1 of this mill. I'm actually very surprised how well the cheap plywood works for this. The only downside is the noise the machine makes during milling. But that is something I can't really change except I build a large box with lots of sound dampening around it. But maybe that's even an option as long as I don't disturb my neighbors.

This board needs some minor cleanup using 400 sandpaper and then it's good to be soldered.

Next steps:

- Find a solution for noise reduction, specifically to the table it's standing on

- Make a new Z-Probe board with mounting holes

- Mount the Z-Probe board in a good location

- Laser cut the power backpack

- Integrate power backpack

- Identify a reliable configuration for drilling all holes with different bit sizes

- Identify a reliable configuration for milling the outlines of any board

- Identify a reliable configuration for milling double sided boards

Timo Birnschein

Timo Birnschein

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.