Tonight I started getting the pulley mould ready. PLA is a low temp plastic, and the heat of the SMA wire damages them quickly. Also, my printer doesn't have the ability to accurately print parts that small.

I printed out a pulley, jammed it on a nail, and put it in my drill press in to make a quick and dirty lathe.

I used some files to grind the pulley to a more circular shape. The result wasn't perfect, but good enough for now.

The next step was filing a target for drilling the cast part and filling the shaft hole with a bit of wax. From my experience holes that small can't be moulded.

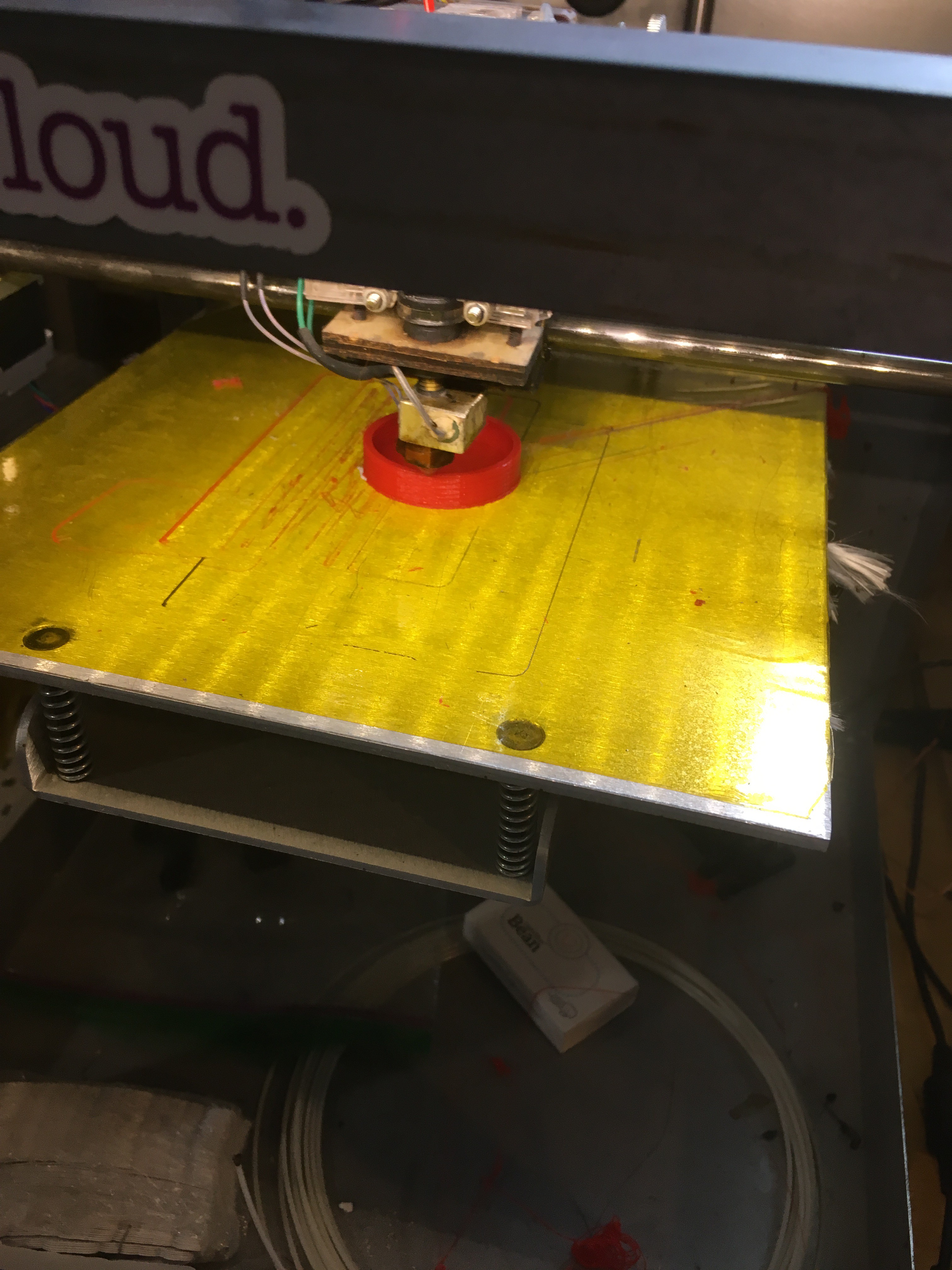

Next I printed out a cup for the mould, placed some nuts in case I want to do a 2 part mould in the future, and I'm waiting for my mixing cups to print.

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.