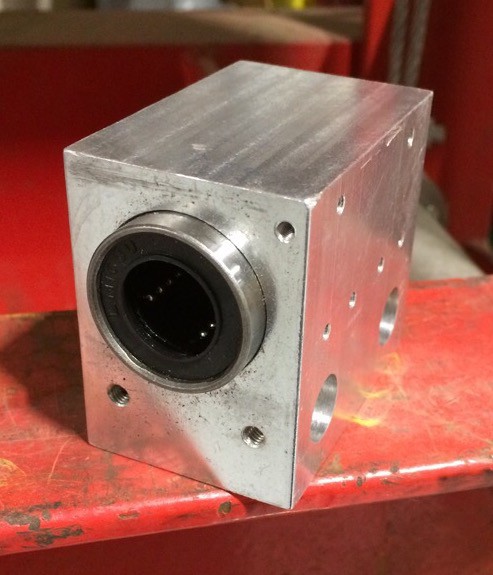

Yesterday I headed over to my local maker space TinkerMill to ream the slide bearing block and press in the new bearing. They have a set of adjustable reamers and a 25 ton hydraulic press. I used a size "I" (capital letter i), and turned it by hand, to remove just enough material to true up the hole and open it up slightly.

It was still a very tight fit, but the giant press handled it no problem. It chattered quite a bit on the way in, and I had to flip it over and back it out a bit to get the bearing centered in the block.

Darryl.N

Darryl.N

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.