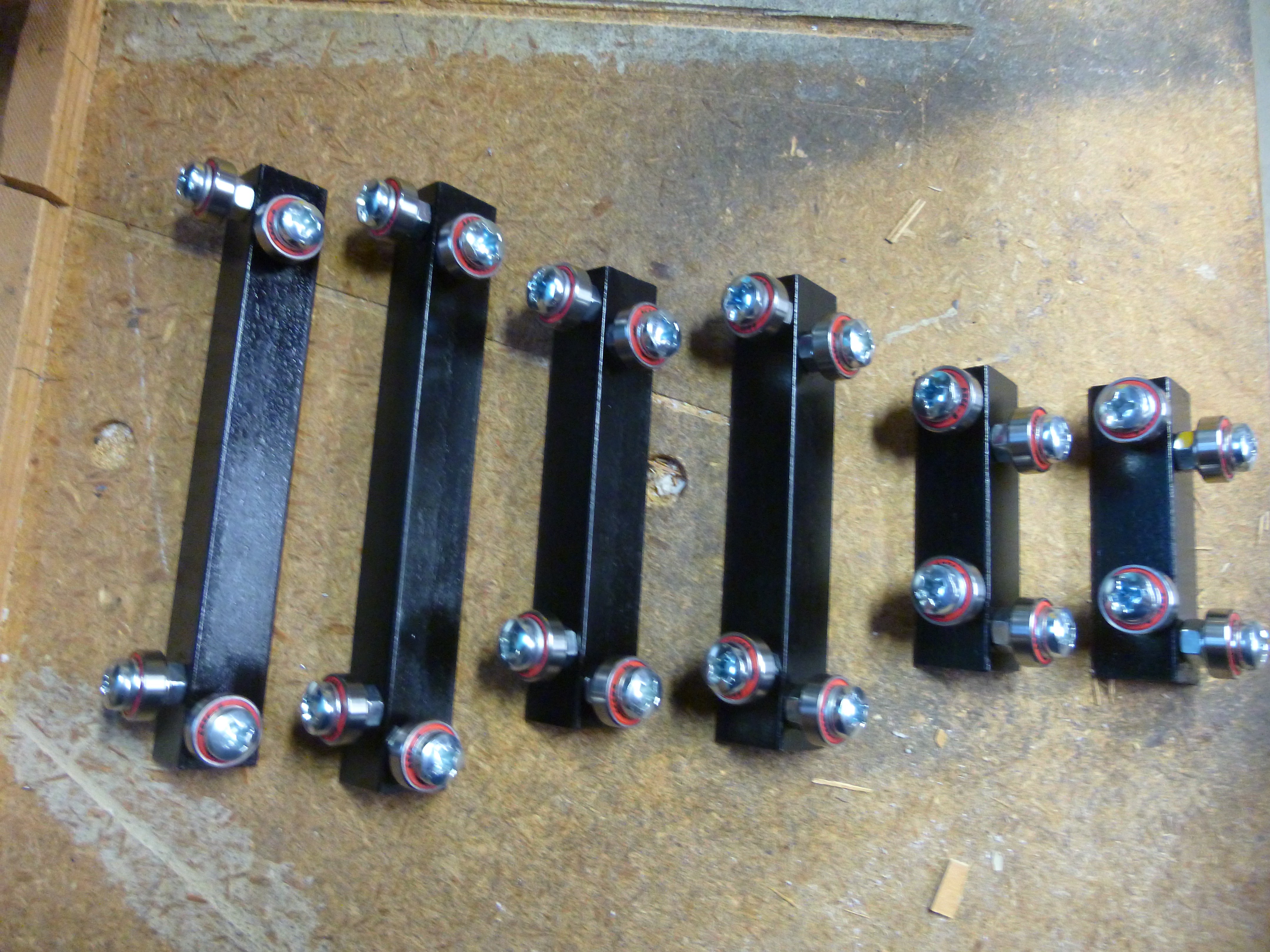

I already decided to modify my plans. Instead of going with 6" trucks for all three axis's. I shrunk the z-axis down to 4", and increased the x-axis to 8".

The trucks are built out of 1/8" steel angle, which was then drilled and tapped for 8mm bolts. the bolts were used to hold the bearing assembly.

I am not sure how well it shows in the image, but my jig is two pieces of scrap wood, nailed together, so the one forms a "wall" to set the angle against. I made a mark at 1" and 1/2", to line the angle against, and drilled away.

I am not sure how well it shows in the image, but my jig is two pieces of scrap wood, nailed together, so the one forms a "wall" to set the angle against. I made a mark at 1" and 1/2", to line the angle against, and drilled away.

After I drilled the holes in the ends of each piece, I tapped the holes for the m8 bolts I was using to hold the bearing assembly together.

Steel_9

Steel_9

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.