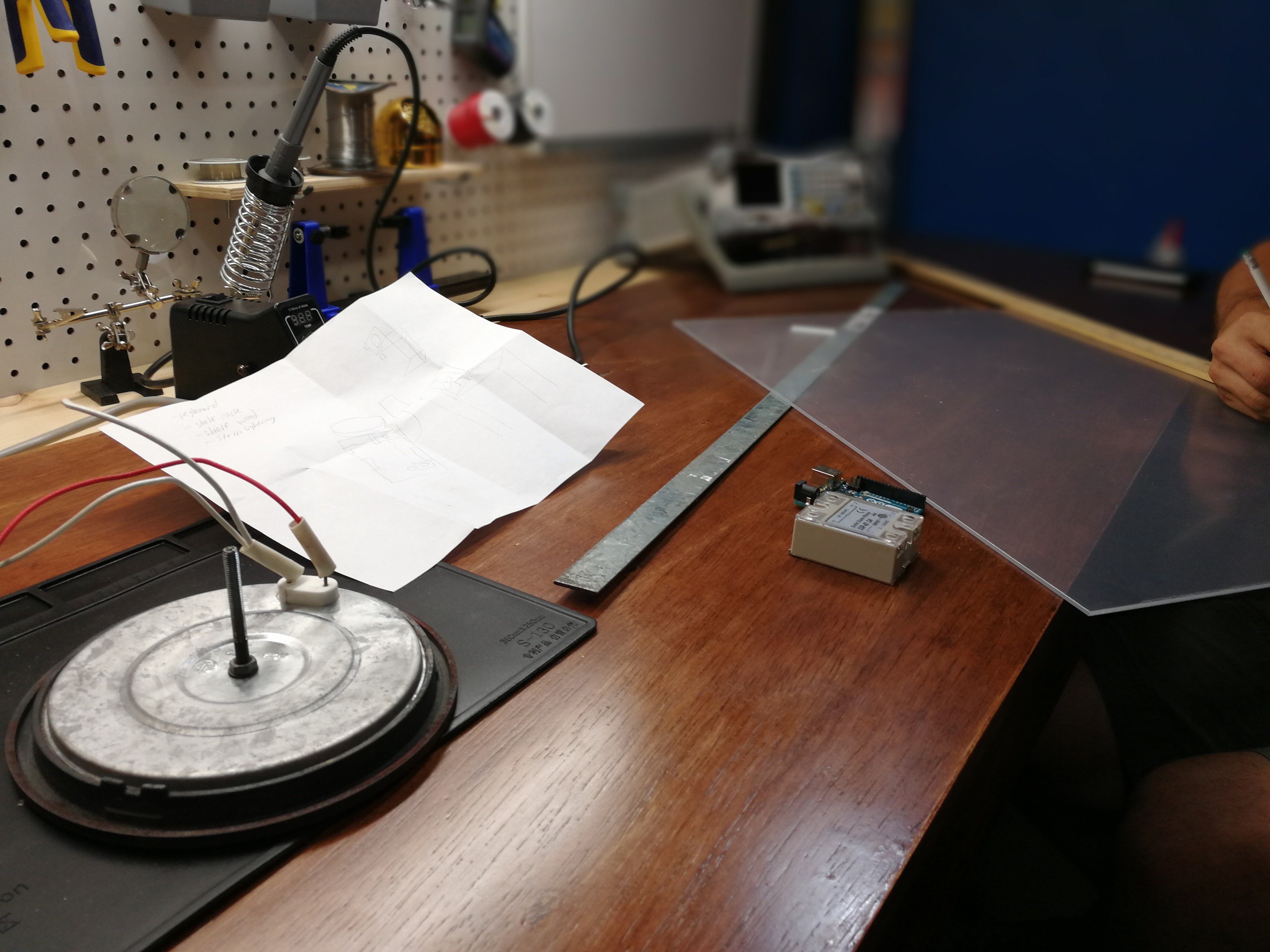

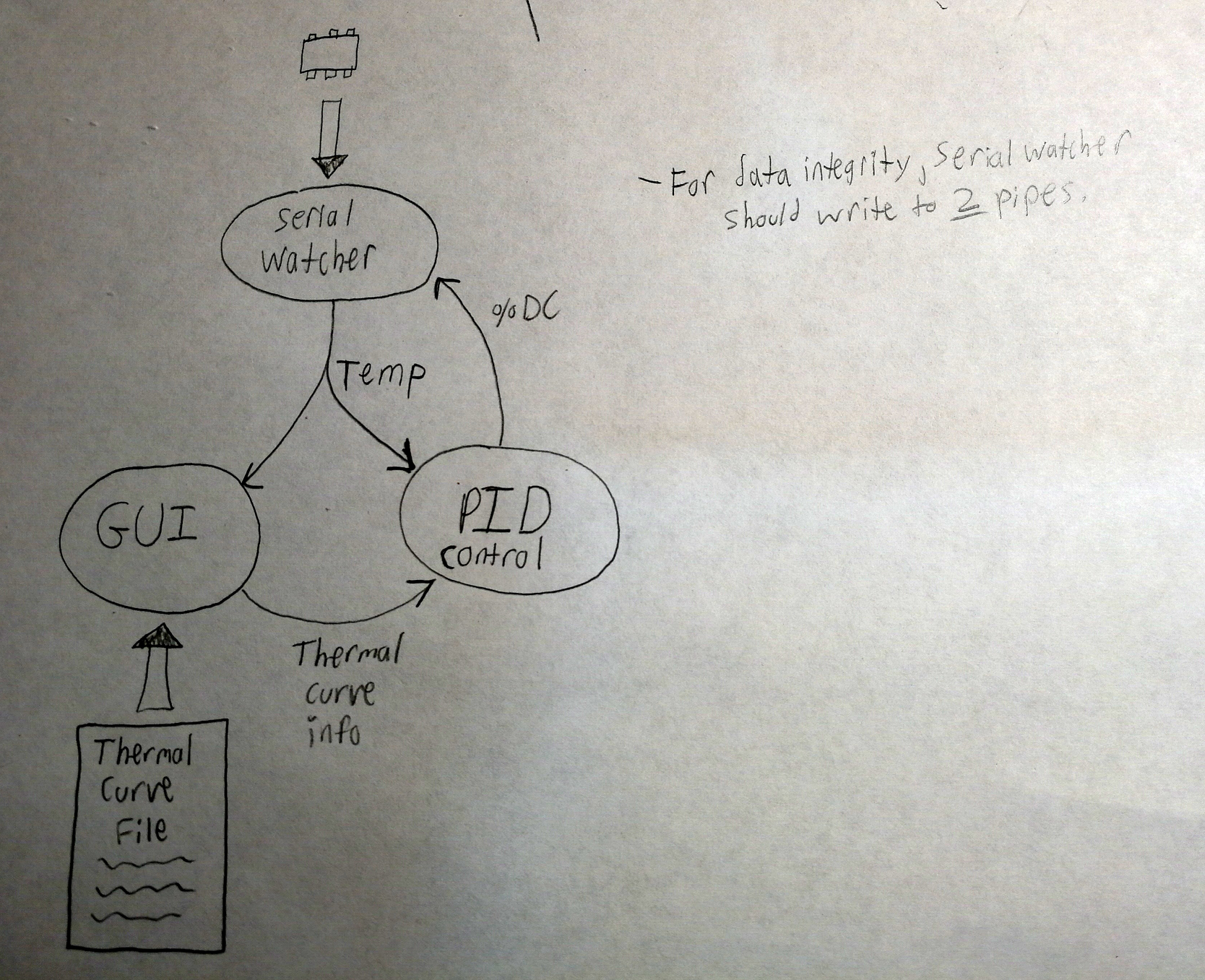

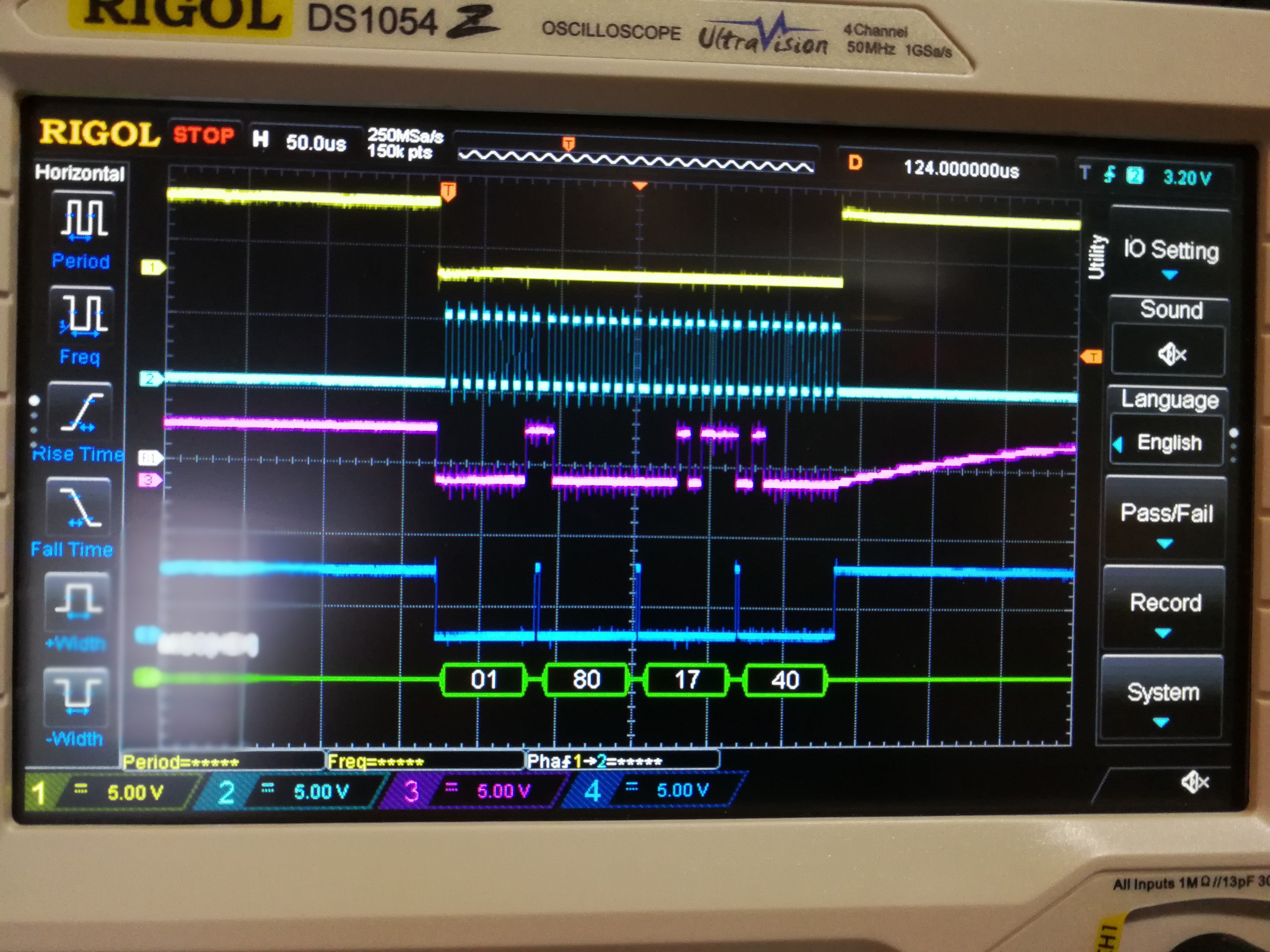

The plan is to use a small AVR microcontroller (ATtiny14?), K-type thermocouple with an Adafruit MAX31855 breakout board, an SSR, and a Python GUI linked to the ucontroller to have a stable temperature controlled hot plate that can have programmable temperature curves to match the solder paste/components to be soldered.

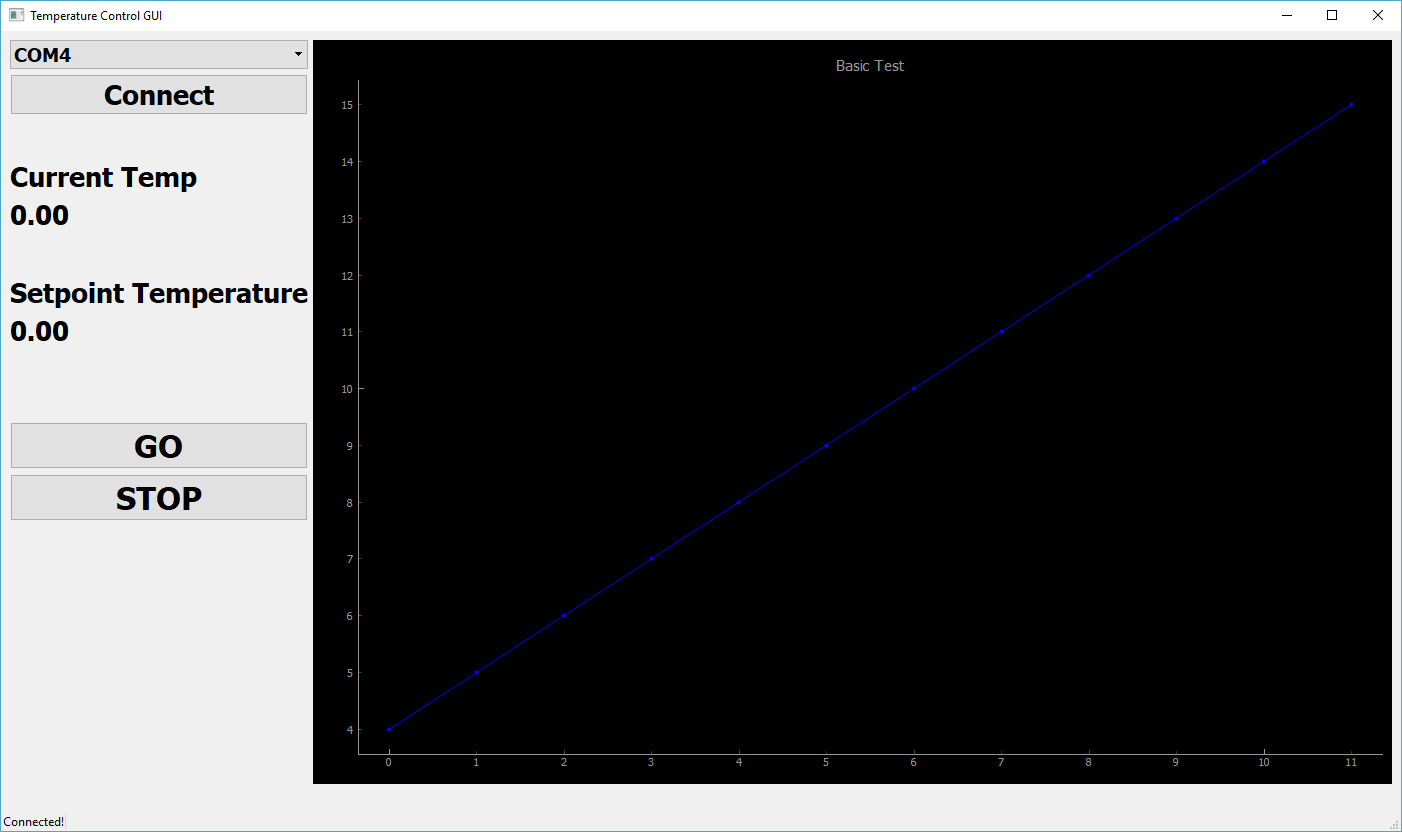

One thing that I think will be different in this project from other DIY reflow hotplates I've seen is that there will be no interface on the reflow oven itself - all the control and brains will be in the GUI on the PC. The ucontroller will really just turn on and off the SSR and read back temperature to the GUI, along with some safety fallbacks such as shutting down the system if things start getting to hot, ucontroller loses communication with the GUI, etc.

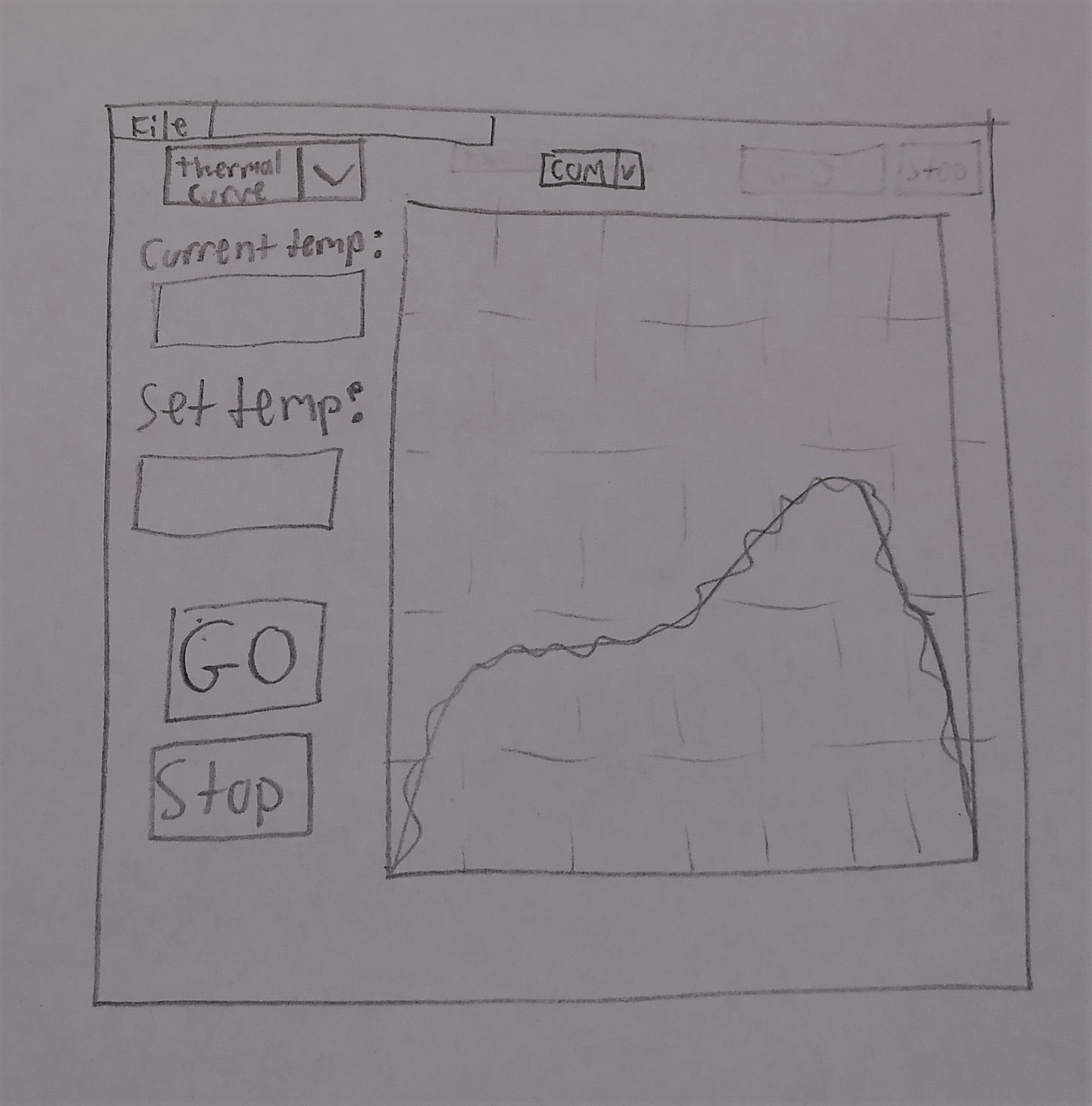

The reason behind not having an interface in the oven is several fold. A) I just don't want to deal with buying, soldering and interface programming to an LCD and various buttons. I kind of want this project to be quick and this is my way of doing that. B) I've been interested in getting better at GUI programming and thread programming. This could be a very very basic introduction to those concepts. C) From what I've seen offloading the temperature curve handling to a PC will allow for much diverse and easy selection of thermal curves and profiles. Want to switch over and perform a chemical reaction that needs exact temperature following? Well the idea is you could simply load up a different CSV file and go, rather than tinkering with two buttons for 10 minutes. It remains to be seen if such complex temperature profiles will ever be needed of course...

Hopefully the end result will be a cheap and versatile temperature controlled hot plate that can mainly be used to reflow small PCBs for projects at home.

Matt Dombroski

Matt Dombroski

Arturo Aldaco Perea

Arturo Aldaco Perea

Dominic DeMarco

Dominic DeMarco

Jorj Bauer

Jorj Bauer

Chris

Chris