Printed parts being drilled

The emitter holders were a different story. They were tapped using an ordinary tap, usually used on metals like mild steel and aluminum (aluminium) but they had no trouble tapping plastic. If these pieces are not tapped, it is necessary to use a nut on them which is a perfectly reasonable solution. If only a few taggers are being built, a tap would be an unwise investment since nuts are so inexpensive.

Tapped Emitter Holders

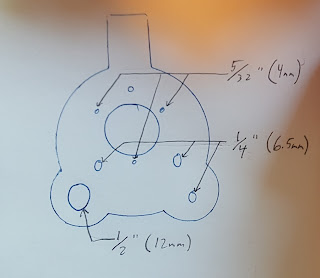

The drill bit sizes were documented on a tracing of the forward array for reference while the rest of the arrays were drilled. The small 5/32" (4mm) holes were for long machine screws 2 1/2" (65mm). The 1/4" (6.5mm) holes were for the LED holders and the 1/2" (12.5mm) holes were for the laser emitters.

Hole sizes for Forward Array

Brian McEvoy

Brian McEvoy

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.