One of the goals of the project is to take it into full production. That means picks that can be precision-replicated, and easily replaceable.

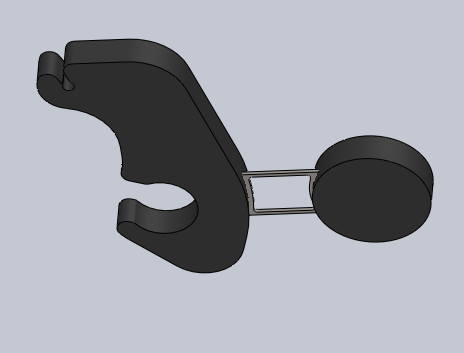

The first versions of the picks were fully captive on the pick axle, which meant you had to slide everything off of the pick bridge to replace a single pick. The latest version snaps into place on the shaft. The outline below shows the main axle snap feature (bottom left), and the control rod snap feature (top left).

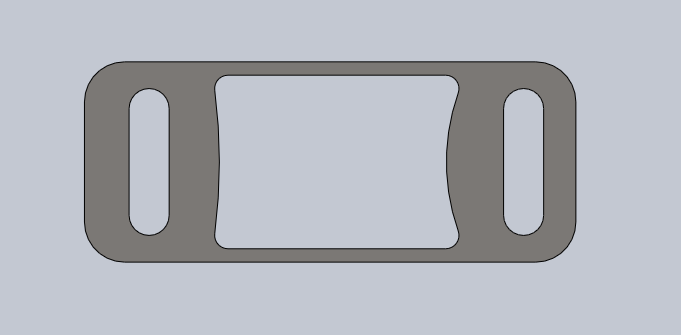

I also replaced the music wire springs with custom-designed, laser-cut leaf springs. They're made of spring-tempered bronze, and will be over-molded into the production picks.

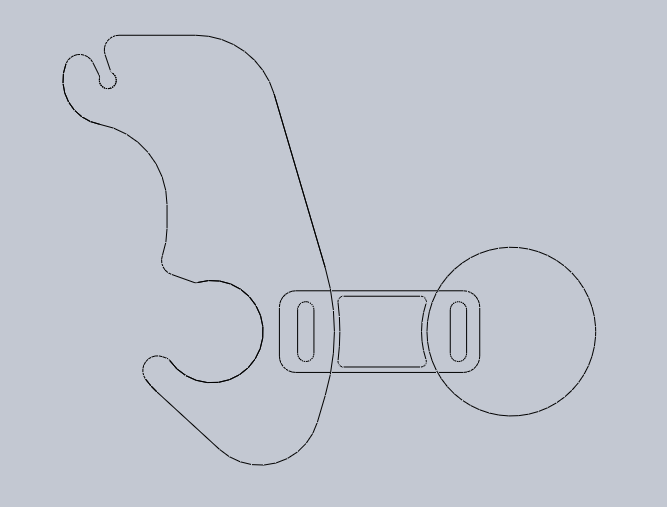

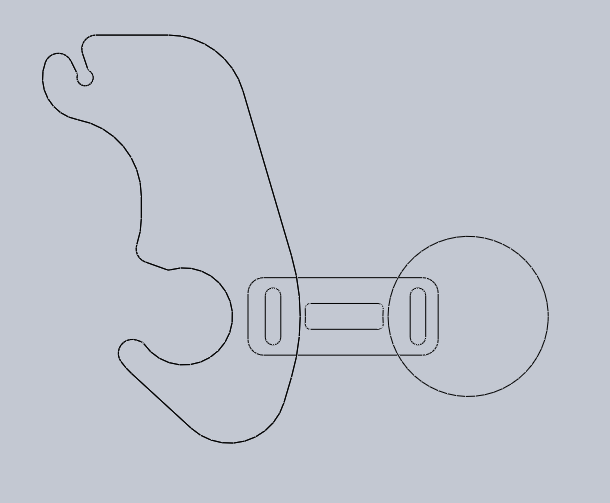

Here's a line drawing, showing how the spring is placed in the pick body:

I designed multiple variants of the leaf springs, each with different stiffnesses. Heavier gauge guitar strings get stiffer leaf springs. This way, you're low E string volume sounds the same as your high E string. The leaf below is stiffer than the one above.

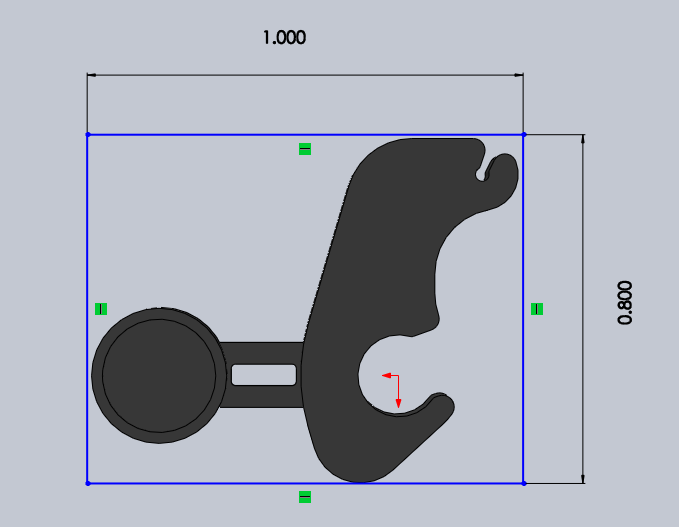

Here's the overall dimensions of a pick:

Of course, I had to try it out. I bought a desktop plastic injection molding machine from LNS technologies:

...had a mold made:

And here's the final product! These are as good as production-ready:

Joe

Joe

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.