MarkII is officially in production phase.

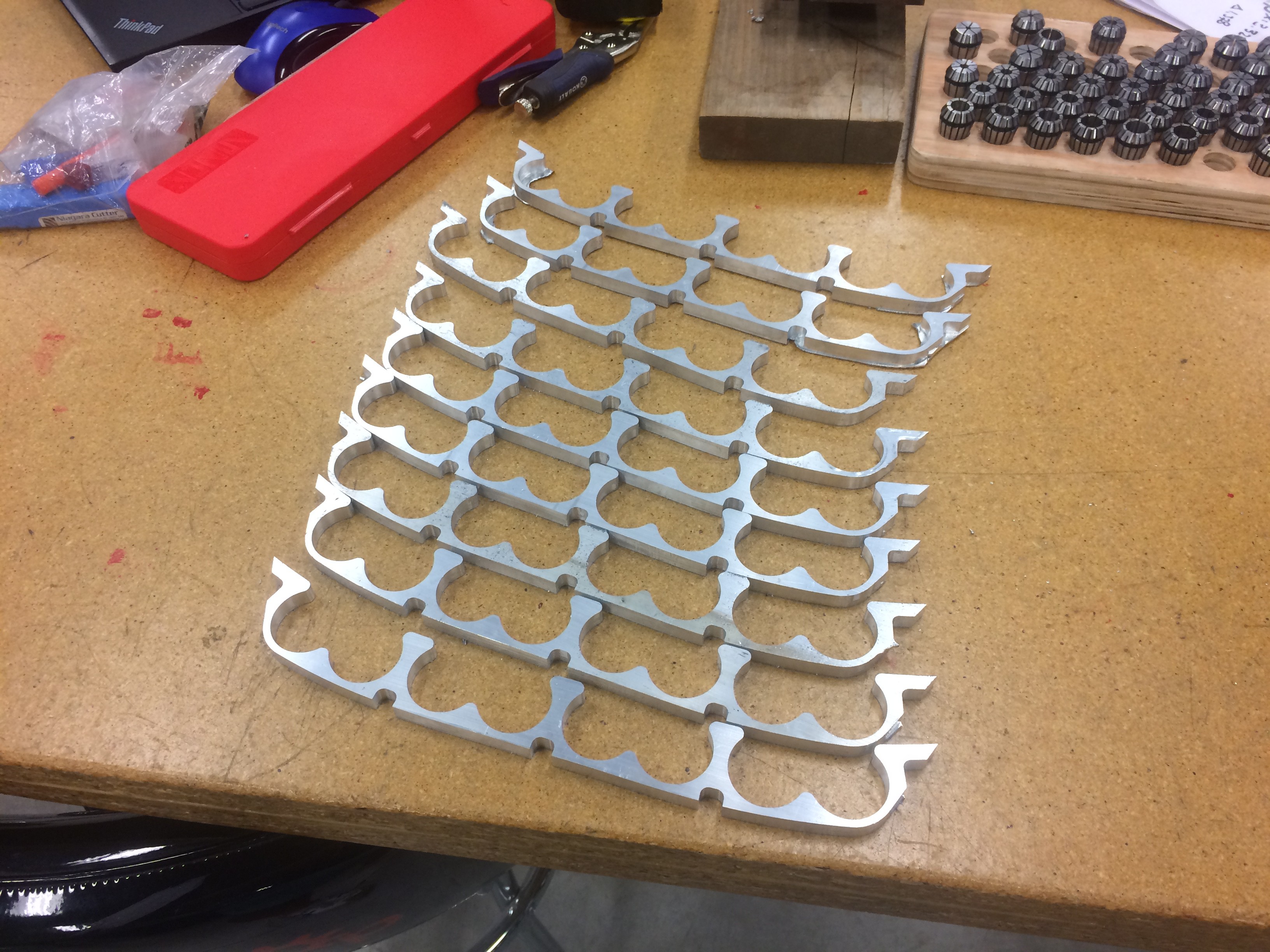

All the mechanical aspects of the board have been (pretty much) finalized, and I am spending my Saturday nights behind a Tormach CNC mill.

I am touching up the MDF mold with a set of chisels, and prepping for the vacuuming procedure.

The issue I am having is that I did not make the truck mounting holes, so the molds are somewhat difficult to align. If I do not figure out how to solve this, It will be back to the CNC wood router for me!

P.S. Waterjet cutters suck.

3$/min runtime and they give you a shit finish. Hence my CNCing.

Danny Andreev

Danny Andreev

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.