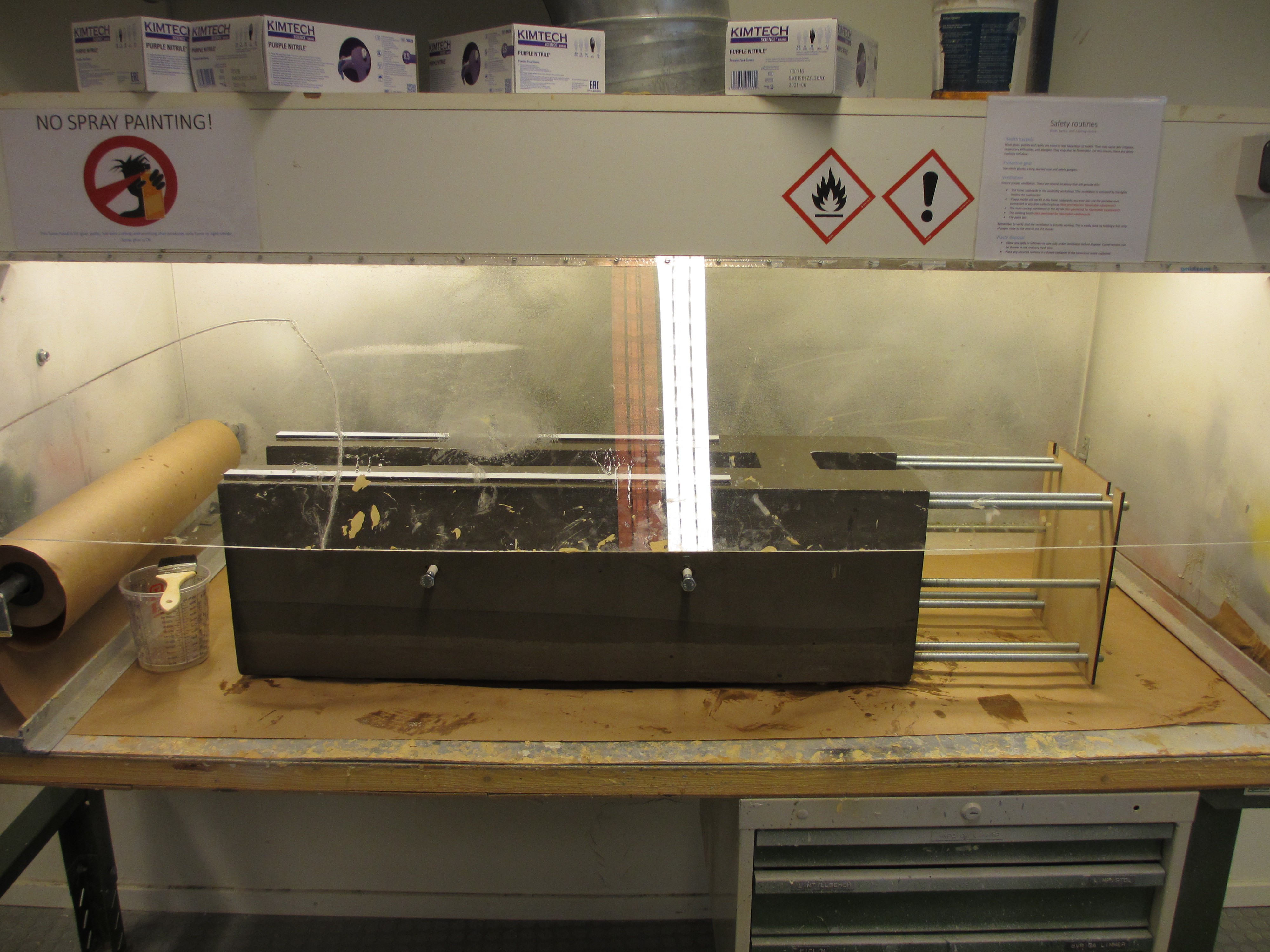

The tower was coated with epoxy as soon as it had cooled down. It was coated inside a fume cupboard. While modern epoxy is not very toxic, proper ventilation is still fantastic.

Besides sealing the concrete, it gives a nice glossy finish to the part.

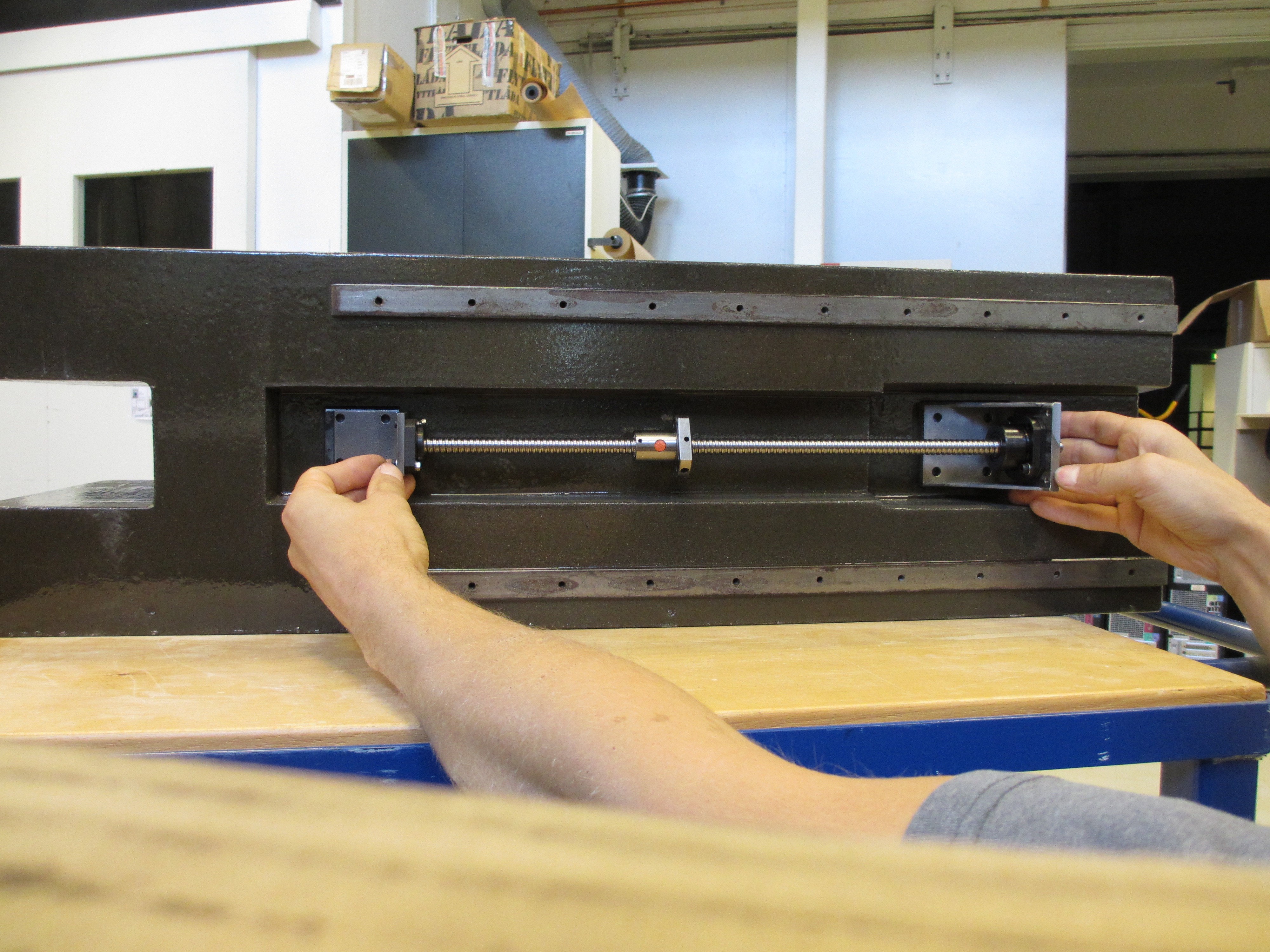

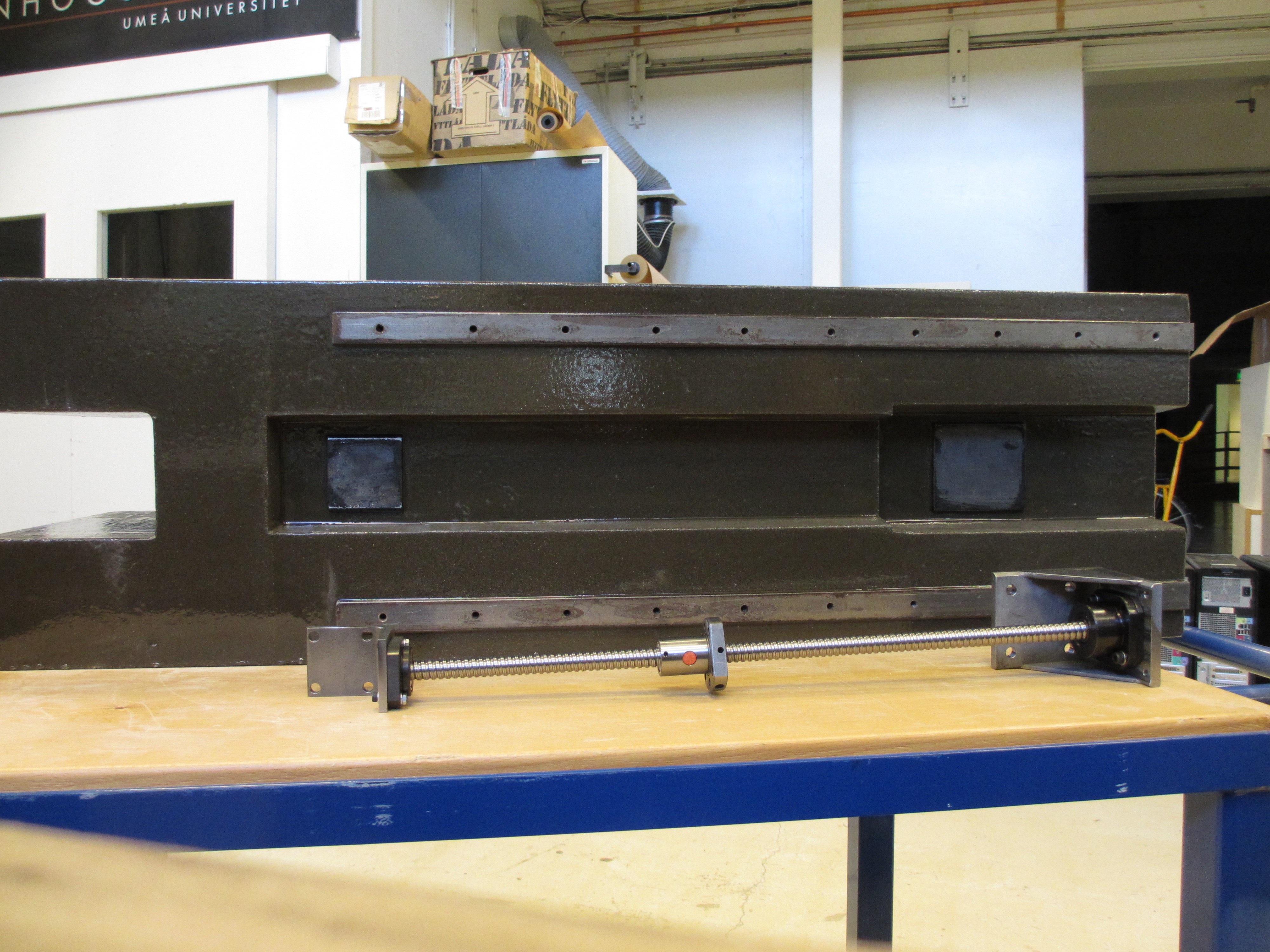

Next up is some mounting hardware for the Z-axis ballscrew.

The one for the floating side is simple, but the one for the fixed side is stiffened and machined on both sides, since it will also hold the stepper motor.

The one for the floating side is simple, but the one for the fixed side is stiffened and machined on both sides, since it will also hold the stepper motor.

Next up is a sanity check regarding the fit. I want to make sure that the steel inserts in the tower matches the mounts and the ballscrew. This is especially important since I'm not drawing anything in CAD, but only building it on the fly.

Looks good!

Next up is machining the steel inserts for precision, and drilling and tapping some holes for the ball screw mounts.

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.